The sheep are now separated into only two flocks now. There is a smaller non-breeding group and the larger group of ewes who are all (hopefully) bred. A couple of days ago I put the young rams, Nash and Rotor back together and their ewes with the rest of the flock. The trick with putting rams together is to crowd them into a small space until they have figured out the pecking order. They will still fight but can’t do as much damage as if they had more room to bash each other. This was too much room even with the barrel taking up space. Rotor, the 4-horn ram was beating the heck out of Nash, the 2-horn. Nash is the bigger ram so it surprised me that Rotor was the dominant one.

The trick with putting rams together is to crowd them into a small space until they have figured out the pecking order. They will still fight but can’t do as much damage as if they had more room to bash each other. This was too much room even with the barrel taking up space. Rotor, the 4-horn ram was beating the heck out of Nash, the 2-horn. Nash is the bigger ram so it surprised me that Rotor was the dominant one. They spent the night in this space and I took out the middle panel the next morning.

They spent the night in this space and I took out the middle panel the next morning. Now they are back in the ram pen and best buddies. This is one of the photos I will send in for Nash’s registration.

Now they are back in the ram pen and best buddies. This is one of the photos I will send in for Nash’s registration. This is Rotor. Both are only 7 months old.

This is Rotor. Both are only 7 months old. Another March lamb I will register is Honey.

Another March lamb I will register is Honey.  After I sent Ringo off to a friend’s farm (when he comes back I’ll have to go through ram introduction all over again) the ewes were in the barn near Faulkner. Is this wishful thinking on his part?

After I sent Ringo off to a friend’s farm (when he comes back I’ll have to go through ram introduction all over again) the ewes were in the barn near Faulkner. Is this wishful thinking on his part? I sent him out to the field with all the ewes.

I sent him out to the field with all the ewes. He found at least one ewe who was interested in him.

He found at least one ewe who was interested in him.

Category Archives: Sheep production

Meanwhile Back at the Ranch…

I am grateful to my friends and family who are taking care of animals and the farm while I am gone. While driving through New Mexico on Tuesday I got a call and a text with this photo. That’s a yearling ram, Foley, with his horns stuck in the 2-year old ram’s upper horn.

That’s a yearling ram, Foley, with his horns stuck in the 2-year old ram’s upper horn.  My two friends had been trying to separate them but couldn’t do it and called for advice. Not only did the rams continue to push against each other but the curved horn was holding the straight horns too tight. What to do? I gave the OK to cut the horn and told them where the wire saw was. But that’s not an easy task. We finally thought of one more person to call–my future daughter-in-law’s brother who lives in the area. Fortunately he was home, came over, and cut Ringo’s horn.

My two friends had been trying to separate them but couldn’t do it and called for advice. Not only did the rams continue to push against each other but the curved horn was holding the straight horns too tight. What to do? I gave the OK to cut the horn and told them where the wire saw was. But that’s not an easy task. We finally thought of one more person to call–my future daughter-in-law’s brother who lives in the area. Fortunately he was home, came over, and cut Ringo’s horn.  That did the trick. Foley was fine but Ringo was a bit worn out–maybe from the angle of his head and neck for the whole time that they were stuck together and the fact that they had been struggling out in the hot sun. (He’s fine now.)

That did the trick. Foley was fine but Ringo was a bit worn out–maybe from the angle of his head and neck for the whole time that they were stuck together and the fact that they had been struggling out in the hot sun. (He’s fine now.) Lyle took the horn home as a souvenir.

Lyle took the horn home as a souvenir.

Once again, thanks to everyone who is helping while I’m gone.

Shearing at the Timm Ranch

Here is where Colleen (Fiber Confections) and I spent last Sunday. I first got fleece from the Timm Ranch, just a few miles from here, last year in preparation for my show at the Artery. Here is a blog post with info about the ranch and photos of the blankets I wove with the wool.  This is a view to the northwest taken while driving through the ranch.

This is a view to the northwest taken while driving through the ranch. Much of the 2700 acres is leased for cattle grazing.

Much of the 2700 acres is leased for cattle grazing. The last gate before the ranch headquarters.

The last gate before the ranch headquarters. There were about 90 ewes, several lambs, and five rams to shear. One group of sheep was already in the barn when we got there but I helped with the second group.

There were about 90 ewes, several lambs, and five rams to shear. One group of sheep was already in the barn when we got there but I helped with the second group.  These are a “ranch mix” developed many years ago and are a blend of Rambouillet, Targhee, and Polypay.

These are a “ranch mix” developed many years ago and are a blend of Rambouillet, Targhee, and Polypay.

The sheep are brought into the barn (on the left)…

The sheep are brought into the barn (on the left)… …move along a lane in the north side of the barn…

…move along a lane in the north side of the barn… …and end up in the pens in the middle where they are visually contained by burlap drapes.

…and end up in the pens in the middle where they are visually contained by burlap drapes.  The shearer pulls the next sheep to shear through the drape and when he is finished the sheep is released and…

The shearer pulls the next sheep to shear through the drape and when he is finished the sheep is released and…

…it walks out the door to the back.

…it walks out the door to the back. The wool is pushed through the window of the barn into a pile where it is later loaded into a wool press that compresses the wool into bales.

The wool is pushed through the window of the barn into a pile where it is later loaded into a wool press that compresses the wool into bales. These bales can weigh 300-400 pounds.

These bales can weigh 300-400 pounds.

In this case Colleen and I diverted many fleeces to our piles and inspected, bagged, and weighed them. I had bagged up my predetermined amount of 200 pounds and was ready to leave (having been battling a cold for days and at this point in the day had completely lost my voice). But then it was time to shear the five rams.

In this case Colleen and I diverted many fleeces to our piles and inspected, bagged, and weighed them. I had bagged up my predetermined amount of 200 pounds and was ready to leave (having been battling a cold for days and at this point in the day had completely lost my voice). But then it was time to shear the five rams. I figured that I’d been there this long. What’s another half hour?

I figured that I’d been there this long. What’s another half hour?

The ram fleeces were gorgeous. Whereas the ewe fleeces weighed 5+ to 8 pounds the ram fleeces I bought weighed 12 pounds (two mature rams) and 8 pounds (the yearling ram with the horns).

The ram fleeces were gorgeous. Whereas the ewe fleeces weighed 5+ to 8 pounds the ram fleeces I bought weighed 12 pounds (two mature rams) and 8 pounds (the yearling ram with the horns).

Last year I had the wool spun into yarn and put on cones (easy for weaving). I think that I’ll have this year’s fiber put into skeins because of the appeal to knitters. Last year’s fiber tested at an average of 23.5 microns. I think I’ll send some more samples in from this year’s wool. Be looking for this yarn in a few (several?) months.

Lambs

I started the last post with a photo of my “lambing board” with two entries. It’s full now… …and there is overflow onto another board. I have 72 lambs with 3 more ewes to lamb. Celeste lambed this morning.

…and there is overflow onto another board. I have 72 lambs with 3 more ewes to lamb. Celeste lambed this morning. These lambs are #71 and 72.

These lambs are #71 and 72.

Most of the others are in the field.

Most of the others are in the field.

That’s no lamb. That’s Puddleduck Petra coming to the barn. You can meet these lambs at our spring open house, Meet the Sheep, Saturday, April 4.

That’s no lamb. That’s Puddleduck Petra coming to the barn. You can meet these lambs at our spring open house, Meet the Sheep, Saturday, April 4.

Reviving a Lamb

I went to the barn a little after 6 a.m. this morning and found what looked like a dead lamb along with two lambs who were up and nursing. The lamb that was flat out on the ground had membranes over his face and was cold and still. I pulled the membranes off of the nose and surprise! That lamb wasn’t quite dead yet. It made a little sound and started to breath raspilly. (Spellcheck says that’s not a word, but it works for me.)

First, get lamb warm. The heat lamp wasn’t fast enough… …so I brought it to the house.

…so I brought it to the house. After it started to revive I substituted a heating pad for the hot water.

After it started to revive I substituted a heating pad for the hot water. Tube feeding with colostrum was next. Fortunately I had a couple of ounces in the freezer.

Tube feeding with colostrum was next. Fortunately I had a couple of ounces in the freezer.  I switched the heating pad from under the lamb to over the lamb while Rusty made sure he didn’t go anywhere.

I switched the heating pad from under the lamb to over the lamb while Rusty made sure he didn’t go anywhere. I carried the whole bundle back to the barn so I could get on with chores. That’s when I set up the heat lamp. I also milked some colostrum out of the mom and tube fed the lamb another few ounces.

I carried the whole bundle back to the barn so I could get on with chores. That’s when I set up the heat lamp. I also milked some colostrum out of the mom and tube fed the lamb another few ounces. It got up before long and now sports the most glamorous in lamb-wear. If a ewe lambs with a single lamb in the next few days I will try to graft this one on. That will be another post.

It got up before long and now sports the most glamorous in lamb-wear. If a ewe lambs with a single lamb in the next few days I will try to graft this one on. That will be another post. These are the other two sets of triplets and their moms.

These are the other two sets of triplets and their moms.

Lambing in Threes – Not Always Pretty

Lambing count so far: 4 sets of twins and 2 sets of triplets. I hope this is not indicative of the rest of lambing season.

After checking Ventura every so often for lambing progress I found her with only a tail hanging out. Not a good sign. I don’t know any other way to deliver a lamb in that position other than to push it back in and find some feet to pull. This is lamb #1. With lamb #1 at 5 lb 6 oz and in an abnormal presentation that’s an indication that this is a triplet delivery.

I don’t know any other way to deliver a lamb in that position other than to push it back in and find some feet to pull. This is lamb #1. With lamb #1 at 5 lb 6 oz and in an abnormal presentation that’s an indication that this is a triplet delivery. Lamb #2.

Lamb #2. Here are all three.

Here are all three.

Ventura with all three lambs the next day. They clean up pretty well.

Here is what I found in the barn this morning: Loretta had one small lamb that had obviously been up for awhile and there were multiple fluid filled membranes. Triplets again? Yes.The second two were trying to come at the same time. Match up a head and two feet and pull that one. The next one comes easily.

Loretta had one small lamb that had obviously been up for awhile and there were multiple fluid filled membranes. Triplets again? Yes.The second two were trying to come at the same time. Match up a head and two feet and pull that one. The next one comes easily.

That third lamb took quite awhile to get going. I let her stay in that sunny spot as long as the sun was there.

That third lamb took quite awhile to get going. I let her stay in that sunny spot as long as the sun was there.

Not triplets but three happy Farm Club members and three babies.

Not triplets but three happy Farm Club members and three babies.

Five Months to Lambs

Monday was Sorting Day (but not like at Hogwarts, although I know that some of you could probably come up with some Harry Potter analogies). It was also the first day of the Spinzilla competition. Spinners from Team Meridian Jacobs were going to gather here in the afternoon but some of the team members are also Farm Club members. Several of them came early to help with sorting ewes and rams into breeding groups. Faulkner, the BFL ram, was first to get his girls and they happy to meet him. I knew that Athena was ready because she had been hanging out next to the fence. But so were Delight, Delilah, and Shelby. Four of the seven ewes with Faulkner were bred yesterday. (The red on the ewes’ rumps is the mark from the crayon in the ram harness.)

Faulkner, the BFL ram, was first to get his girls and they happy to meet him. I knew that Athena was ready because she had been hanging out next to the fence. But so were Delight, Delilah, and Shelby. Four of the seven ewes with Faulkner were bred yesterday. (The red on the ewes’ rumps is the mark from the crayon in the ram harness.)

Next up was Crosby, a lilac ram lamb. I wasn’t going to use him this year because it’s hard to split the flock into too many groups. But transport for the ram that I am buying is now delayed so I thought I’d give Crosby a shot. He just got back from Lambtown where he won Champion ram of the Primitive Breeds division. It was a small show, but a win is a win, right? The judge loved his fleece and so do I.

He just got back from Lambtown where he won Champion ram of the Primitive Breeds division. It was a small show, but a win is a win, right? The judge loved his fleece and so do I. The girls, however, were not as impressed. It seems that ribbons aren’t everything.

The girls, however, were not as impressed. It seems that ribbons aren’t everything. To Crosby’s credit he tried hard…

To Crosby’s credit he tried hard… …he didn’t give up…

…he didn’t give up… …but to no avail. None of the four ewes wanted much to do with him. I don’t have a photo but I did see him finally lying down by the fence looking exhausted and dejected.

…but to no avail. None of the four ewes wanted much to do with him. I don’t have a photo but I did see him finally lying down by the fence looking exhausted and dejected. Alex was ready for his ewes. He is a yearling ram whose fleece is beautiful. I didn’t try to use him as a lamb last year because he had bluetongue in the fall. Even if he could have bred, he likely would have been sterile from the high fever.

Alex was ready for his ewes. He is a yearling ram whose fleece is beautiful. I didn’t try to use him as a lamb last year because he had bluetongue in the fall. Even if he could have bred, he likely would have been sterile from the high fever.

Out of his group of 14 ewes, Alex found only one ewe who was interested.

Out of his group of 14 ewes, Alex found only one ewe who was interested.

Poor Celeste. With no one else interested in him, Celeste got all Alex’s attention. Good thing that I moved Shearing Day to January. Hopefully rain will wash out some of this color.

Poor Celeste. With no one else interested in him, Celeste got all Alex’s attention. Good thing that I moved Shearing Day to January. Hopefully rain will wash out some of this color.

The rest of the flock is waiting for a ram to show up in a few weeks. Lambing season will be a bit longer this year.

Sheep Grow Up

I didn’t get around to registering most of the lambs that I kept last year. JSBA was in transition from me being the Registrar to having an outside organization handle it. So I waited. Why add more workload? Besides, the applications can now be submitted electronically (no more printing lots of photos for each sheep) and photos will show up on the registration certificates. Here are the sheep that I submitted, now yearlings. Meridian Santana = Puddleduck Sullivan x Genesis Farms Belinda

Meridian Santana = Puddleduck Sullivan x Genesis Farms Belinda Meridian Alex = Kenleigh’s Matrix x Meridian Alexandria

Meridian Alex = Kenleigh’s Matrix x Meridian Alexandria Meridian Lana = Meridian Fogerty x Meridian Loretta

Meridian Lana = Meridian Fogerty x Meridian Loretta Meridian Raquel= Meridian Miller x Meridian Rosie

Meridian Raquel= Meridian Miller x Meridian Rosie Meridian Cascade = Meridian Miller x Meridian Sierra

Meridian Cascade = Meridian Miller x Meridian Sierra Meridian Mae = Meridian Miller x Meridian Mary

Meridian Mae = Meridian Miller x Meridian Mary Meridian Sophia = Kenleigh’s Matrix x Meridian Jazz

Meridian Sophia = Kenleigh’s Matrix x Meridian Jazz This is Marilyn who was registered last year so I didn’t get a new photo of her. This photo is before shearing her as a lamb. Marilyn = Meridian Miller x Meridian Hot Lips.

This is Marilyn who was registered last year so I didn’t get a new photo of her. This photo is before shearing her as a lamb. Marilyn = Meridian Miller x Meridian Hot Lips. This is some of Marilyn’s wool. I am spinning her fleece now during the Tour de France as part of Meridian Jacob’s unofficial Tour de Fleece group on Ravelry. Join us!

This is some of Marilyn’s wool. I am spinning her fleece now during the Tour de France as part of Meridian Jacob’s unofficial Tour de Fleece group on Ravelry. Join us!

Who will the 2014 keepers be? This is one. Meridian Ginny = Meridian Hendrix x Mud Ranch’s Ginseng

This is one. Meridian Ginny = Meridian Hendrix x Mud Ranch’s Ginseng Maybe this one shown with her mom. Not named yet = Meridian Miller x Meridian Vicki.

Maybe this one shown with her mom. Not named yet = Meridian Miller x Meridian Vicki. Meridian Miller x Meridian Jane

Meridian Miller x Meridian Jane Meridian Hendrix x Meridian Alison

Meridian Hendrix x Meridian Alison

Road Trip – 2nd half of Day 8 – Oregon

After touring Pendleton Woolen Mill we got on the road again. Just as we were getting on the freeway to head west we saw this scene: Herding cattle next to the freeway and across lawn? Look again.

Herding cattle next to the freeway and across lawn? Look again. These are beautifully made full-size sculptures.

These are beautifully made full-size sculptures. Not far from Pendleton Highway 84 meets up with and then follows the Columbia River.

Not far from Pendleton Highway 84 meets up with and then follows the Columbia River.  We followed the Columbia River. This is the John Day Lock and Dam.

We followed the Columbia River. This is the John Day Lock and Dam. In some places we saw windsurfers on the river, but elsewhere there were huge barges. I don’t have photos but we also saw several bighorn sheep on the rocky cliffs just south of the highway in this area.

In some places we saw windsurfers on the river, but elsewhere there were huge barges. I don’t have photos but we also saw several bighorn sheep on the rocky cliffs just south of the highway in this area.  We turned south onto Highway 97 which would take us all the way to California.

We turned south onto Highway 97 which would take us all the way to California. More stunning landscape, sky and wide, open spaces.

More stunning landscape, sky and wide, open spaces. Rolling hills of wheat.

Rolling hills of wheat. Isolated ranches and distant mountains.

Isolated ranches and distant mountains.

We passed the town of Shaniko (population of 36 at 2010 census) which was known in 1900 as the Wool Capitol of the World. The largest landowner at the time was R.R. Hinton who had first homesteaded in the 1870’s and continued to purchase land until his Imperial Stock Ranch became the largest individually owned ranch in Oregon. The Imperial Stock Ranch eventually ran 35,000 head of sheep in 12-14 bands that would winter on the home ranch and be trailed to summer range on Forest Service land. Hinton was involved in breeding programs that led to the one of the first sheep breeds developed in the U.S., the large-framed, fine-wooled Columbia sheep, originating from Lincoln and Rambouillet ancestors. The newly formed town of Shaniko (built as the railroad reached the area) was less than 15 miles from the Imperial Stock Ranch’s headquarters, and its wool warehouse shipped 4 million pounds of wool by rail in 1901. Imperial Stock Ranch is now owned by Dan and Jeannie Carver and they have developed the Imperial Yarn Company using Columbia wool produced on the ranch and elsewhere in the state. This is some of my favorite yarn in the shop and I have recently been using it to weave blankets. Since we were going to be driving through this part of Oregon I had asked if we could visit the ranch. The photo above is the road into the headquarters.

Imperial Stock Ranch is now owned by Dan and Jeannie Carver and they have developed the Imperial Yarn Company using Columbia wool produced on the ranch and elsewhere in the state. This is some of my favorite yarn in the shop and I have recently been using it to weave blankets. Since we were going to be driving through this part of Oregon I had asked if we could visit the ranch. The photo above is the road into the headquarters.

Keelia, lives on the ranch and was there to show us around the headquarters. This is the house built by R.R. Hinton, now headquarters of the Yarn Company. The headquarters complex has been entered into the National Register of Historic Places and the history of the buildings and the Hinton family are available for review.

The headquarters complex has been entered into the National Register of Historic Places and the history of the buildings and the Hinton family are available for review.

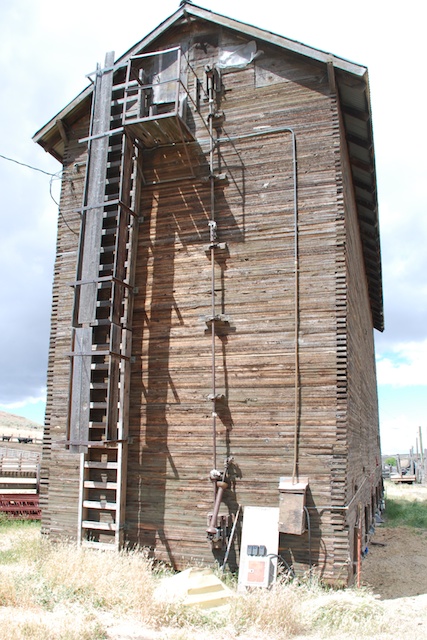

The grain silo. See the detail of the construction below.  This is one sturdy building. We also saw the shearing shed and other buildings that are still in use.

This is one sturdy building. We also saw the shearing shed and other buildings that are still in use. A few bottle lambs hand out under the house to greet visitors.

A few bottle lambs hand out under the house to greet visitors. As we left the ranch headquarters some of the sheep were near enough the road to get some photographs of them in this majestic setting.

As we left the ranch headquarters some of the sheep were near enough the road to get some photographs of them in this majestic setting.

Back on the road on the last leg of the trip.

Back on the road on the last leg of the trip.

Next post: California’s scenery isn’t too shabby either. Mt. Shasta and home.

Spring Shearing in a Big Way

A couple of friends and I went to see shearing on a commercial sheep ranch about 30 miles south of here. We got there in just enough time to see the last part of shearing 3000 sheep in 2 1/2 days. The original flock was made up of Corriedale sheep and over the years was crossed with Targhee and other commercial white-faced sheep.

The original flock was made up of Corriedale sheep and over the years was crossed with Targhee and other commercial white-faced sheep.  The sheep are gathered at the back of a trailer that is hauled from ranch to ranch with all the gear. They go up the chute with the encouragement of…

The sheep are gathered at the back of a trailer that is hauled from ranch to ranch with all the gear. They go up the chute with the encouragement of… …Border Collies as well as people.

…Border Collies as well as people. Here is a view from the other end of the trailer. That sheep in front hangs out for awhile in that position because the other sheep are more likely to go forward if they see a sheep in front of them. Notice how the sheep walk on a raised alleyway while the freshly shorn fleeces are shoved out of the trailer below them.

Here is a view from the other end of the trailer. That sheep in front hangs out for awhile in that position because the other sheep are more likely to go forward if they see a sheep in front of them. Notice how the sheep walk on a raised alleyway while the freshly shorn fleeces are shoved out of the trailer below them. Here is a photo of the inside of the trailer. There are seven shearers at work. The sheep walk forward on the raised alley. Fleeces are pushed out beneath.

Here is a photo of the inside of the trailer. There are seven shearers at work. The sheep walk forward on the raised alley. Fleeces are pushed out beneath. When the shearer is ready for the next sheep he pulls the door down with his foot and flips the sheep off the alleyway into position for shearing.

When the shearer is ready for the next sheep he pulls the door down with his foot and flips the sheep off the alleyway into position for shearing.

After the sheep are shorn they are sent out the doors on the other side of the trailer.

After the sheep are shorn they are sent out the doors on the other side of the trailer.

The fleeces are scooped from the trailer and quickly examined by a sorter/classer who determines where they end up.

The fleeces are scooped from the trailer and quickly examined by a sorter/classer who determines where they end up.

The fleeces are thrown into the appropriate pile. My friends who owns the ranch had requested that the finer fleeces shorn on that day be put aside for us to look at. It turns out that even the not-so-fine fleeces seemed just as nice to us. Last year’s core samples indicated that most of this flock’s wool graded in the mid-20’s (microns) and the finer fleeces were in the low 20’s. For reference Jacob fleece ranges from about 25-35 microns and most of mine is probably about 28 to 29 microns. So all of this wool is finer than what I am used to using.

The fleeces are thrown into the appropriate pile. My friends who owns the ranch had requested that the finer fleeces shorn on that day be put aside for us to look at. It turns out that even the not-so-fine fleeces seemed just as nice to us. Last year’s core samples indicated that most of this flock’s wool graded in the mid-20’s (microns) and the finer fleeces were in the low 20’s. For reference Jacob fleece ranges from about 25-35 microns and most of mine is probably about 28 to 29 microns. So all of this wool is finer than what I am used to using. The fine fleece pile is the one nearest the table. The pile to the left are tender fleeces (fleeces that have a weak place usually due to nutritional stress or illness). The pile just barely visible behind the plywood is the “not as fine” pile. We chose our fleeces (all of the fine pile and a lot of the one behind the plywood) and the remaining wool was quickly baled.

The fine fleece pile is the one nearest the table. The pile to the left are tender fleeces (fleeces that have a weak place usually due to nutritional stress or illness). The pile just barely visible behind the plywood is the “not as fine” pile. We chose our fleeces (all of the fine pile and a lot of the one behind the plywood) and the remaining wool was quickly baled.

The wool is shoved into this wool press…

The wool is shoved into this wool press…

…and compacted… …and sealed into bales that are marked with the pertinent information. I forgot to ask how much these weigh but on-line sources say they would hold 240 to 450 pounds each.

…and sealed into bales that are marked with the pertinent information. I forgot to ask how much these weigh but on-line sources say they would hold 240 to 450 pounds each. Before we left the shearing trailer was pulling out and everyone was getting ready to go to the next job.

Before we left the shearing trailer was pulling out and everyone was getting ready to go to the next job. Freshly shorn sheep turned out to graze.

Freshly shorn sheep turned out to graze.

In about six months I hope to have blankets woven from this wool. They will be available at the Artery and the Fibershed Marketplace.