As the title indicates, I have already written one blog post about lambing. That described that lambing began on February 22. That’s nine days ago now, and a lot has happened. I started this post yesterday and it’s already outdated. However, I’m going to go with it because these photos are already loaded. Just play along and pretend it’s Monday. I was sharing photos in reverse order. Now I just need to add the text.

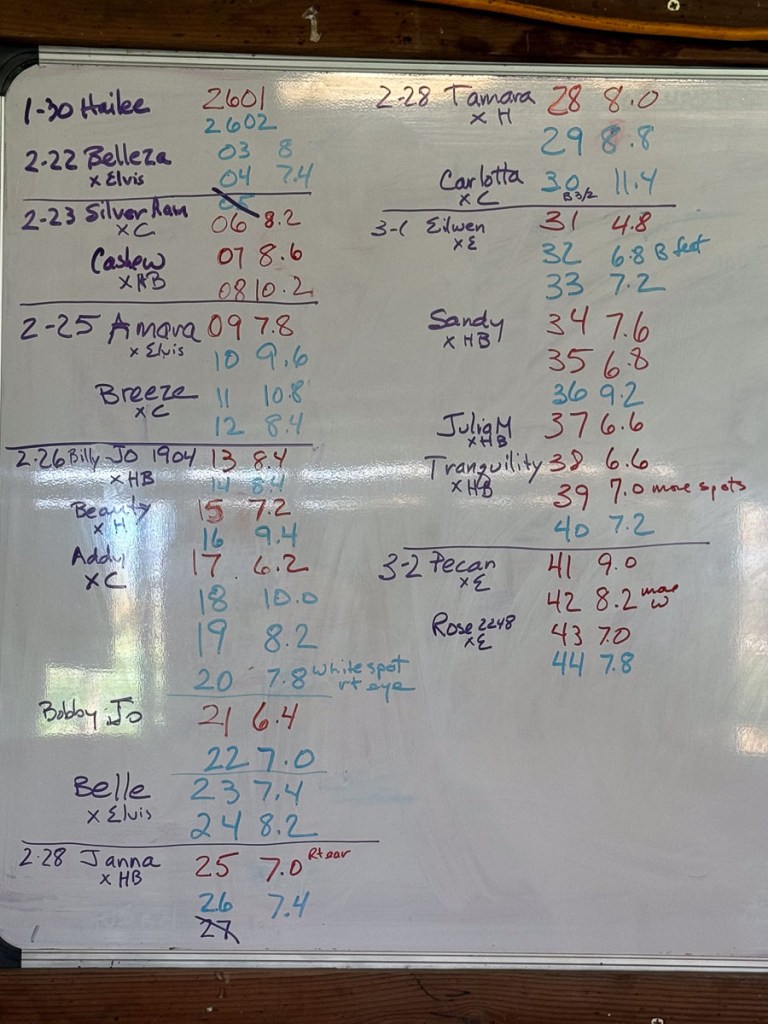

This is how I keep track of all the details. The numbers are the lamb ID, each with a 26 in front. Red ones are ewe lambs and blue are ram lambs. The next column is birth weight. The X _ indicates the sire: Hornblower, Clancy (BFL), Elvis, and Hunter.

The last one on the board is Rose with twins. I usually try to have them in the lambing pen area when they are in labor but I missed this one.

Pecan was just before Rose with twins.

Tranquility lambed the night before with triplets.

This is how Tranquility looked earlier in the day. When a ewe gets that sunken look in front of the hips that is a sign that the lambing is imminent. Maybe imminent isn’t the right word because I put her in the lambing area earlier in the day and she didn’t deliver until about 10:30 p.m.

Julia is a yearling who lambed in the pasture. One of the Farm Club members who was here brought her lamb to the barn, carrying it low so the ewe would follow.

Sandy had lambed earlier in the morning with triplets. I set up panels to separate Sandy from Eilwen (next photo). This is like having hospital beds in the hall. The lambing pens were full and I already had overflow pens in the alley of the barn.

Eilwen with triplets around 2 a.m.

At night the chickens roost on the wall behind the lambing pens.

This is Carlotta from the previous day. She is a Romney/Lincoln/Corriedale cross. The lamb’s sire is Clancy, the BFL.