My largest loom is 60″ wide. A queen-size blanket is supposed to be about 90″ wide. When I weave a large blanket (full or queen size) I use double weave. This means that I weave two layers of cloth at the same time and they are connected on one side. When the blankets comes off the loom I open it up and it is double-width.

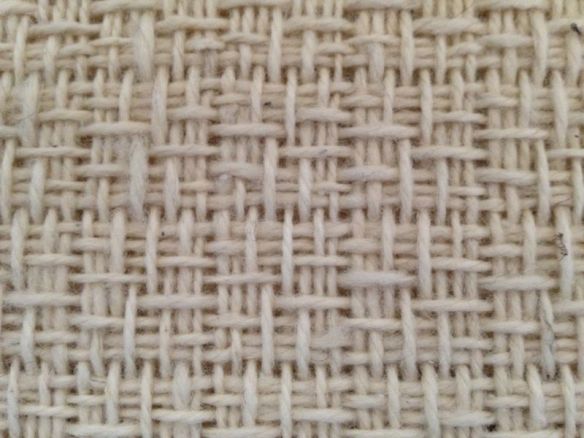

Sometimes things don’t go as planned. Here is an example: That is a big OOPS on the underside. (And that wasn’t the only one on this warp of two blankets. In fact some of you might notice another error that was THROUGHOUT the whole warp.) Both of these errors were fixable–it just takes time…and patience…

That is a big OOPS on the underside. (And that wasn’t the only one on this warp of two blankets. In fact some of you might notice another error that was THROUGHOUT the whole warp.) Both of these errors were fixable–it just takes time…and patience… …and a good audio book. Here is how I fixed the most obvious error (all those skipped warp threads).

…and a good audio book. Here is how I fixed the most obvious error (all those skipped warp threads). I knew that I could pull the warp threads out and needle weave them all the way back to the end of the warp (about 30″ I think). I found the correct path above the error and marked it with a needle. It’s not just a simple over-under. I think this pattern was under 2, over 1, under 1, over 1, under 1, over 2. I really didn’t want to have to do that pattern with a needle for all of those threads. So I tied a thin thread (brown) to the warp thread (wool yarn) that needed to be rewoven and as I pulled it out the brown thread held the place.

I knew that I could pull the warp threads out and needle weave them all the way back to the end of the warp (about 30″ I think). I found the correct path above the error and marked it with a needle. It’s not just a simple over-under. I think this pattern was under 2, over 1, under 1, over 1, under 1, over 2. I really didn’t want to have to do that pattern with a needle for all of those threads. So I tied a thin thread (brown) to the warp thread (wool yarn) that needed to be rewoven and as I pulled it out the brown thread held the place.

Then I untied the brown thread from the wool yarn. Using a tapestry needle I wove the wool yarn over and under the correct yarns in the area where there was a skip.

Then I untied the brown thread from the wool yarn. Using a tapestry needle I wove the wool yarn over and under the correct yarns in the area where there was a skip.  Then I tied the brown thread back to the wool yarn and pulled it all the way through to the end of the blanket….for all those threads. After fixing other errors the blankets were washed and they are finally in the mail.

Then I tied the brown thread back to the wool yarn and pulled it all the way through to the end of the blanket….for all those threads. After fixing other errors the blankets were washed and they are finally in the mail.

Here is the stack of blankets that I sent to the customer. There are 8 throws and 2 queen blankets (the ones on the bottom of the stack).

Gathering around a loom to talk about this sample. We wove a series of sample treadlings that showed varying amounts of each of the two warp layers and then we learned pick-up, changing sheds (opening between threads) three times in each pick (row of weaving)…

Gathering around a loom to talk about this sample. We wove a series of sample treadlings that showed varying amounts of each of the two warp layers and then we learned pick-up, changing sheds (opening between threads) three times in each pick (row of weaving)…