I scheduled a Farm Day today to take care of some chores prior to shearing next week. The ewes were ready to be vaccinated to provide the highest level of antibodies in the colostrum. I wanted to clip fleece samples from the yearlings (their second fleeces) to send in for micron testing. We also made sure that the ear tags were clean enough to read and that the tags would match the cards that go with each fleece.

Some long-time Farm Club members were there as well as some people who are new to Farm Club. It all went very smoothly and it took only a couple of hours to work through all the sheep and take time to take a closer look at some of those fleeces.

Farm Club members get a chance to reserve a fleece at this Fleece Preview Farm Day.

Deborah took the photos from above and this is me remembering to take at least a few photos. Often we get so busy that I overlook that.

While most of us were in with the sheep Susan, Chris, and Nikki volunteered to clean behind the barn. That’s always a big chore. When they finished here they moved to the ram pen and cleaned the ram barn.

Mary checked off the list on the clip board and made sure the cards matched the ear tags. Susan drew up vaccine into syringes.

Marina and Katy caught sheep, marked faces, and cleaned ear tags.

Rachel and Siobhan also helped catch and mark sheep.

The photos below are what it is all about. I had been thinking that the sheep are looking a bit bedraggled, but when I got hands-on those fleeces I changed my mind. They are looking good.

April is a yearling ewe, almost 2 year old.

Queen Q is the same age. The photos below are an on-the-hoof look at the fleeces of the four rams I have here.

Meridian Blizzard (Meridian Silverado x Meridian Bessie), 10 month old ram.

Meridian Typhoon (Meridian Turbo x Meridian Rocha)

Fair Adventure Horatio, 3 year old ram, from Colorado.

Hillside Gabby’s Barrett, 3 year old ram, from Michigan.

Shearing Day is Sunday, January 21.* We’ll be shearing about 70 sheep. Fleeces are available on shearing day and for a month or two afterwards as I skirt them and post them on-line. If you live in the area you can come here to choose a fleece. Contact me.

*I just fixed this. A friend pointed out that I wrote June 21. Yikes!

into the corner at the end of the room. I didn’t finish until the next day.

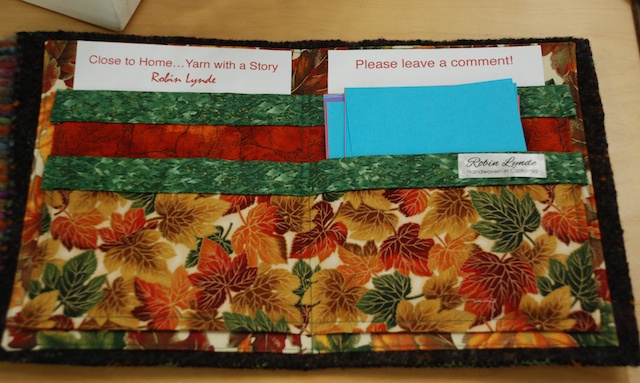

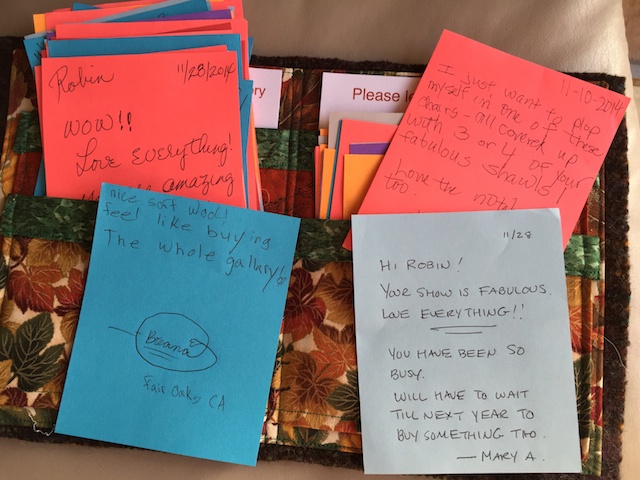

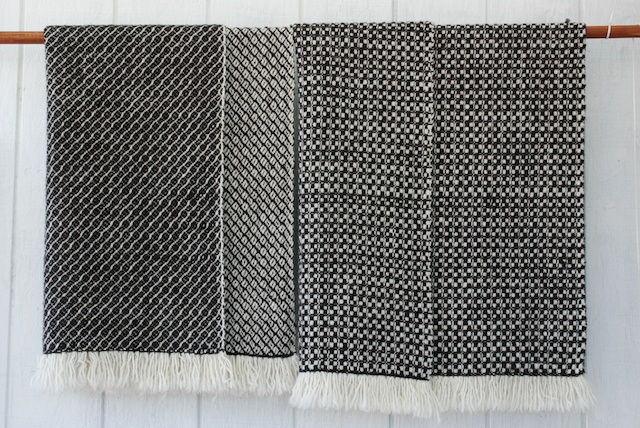

into the corner at the end of the room. I didn’t finish until the next day. This is some of the blankets all tagged and ready to show again.

This is some of the blankets all tagged and ready to show again.

This is one of only two yarns in this show that are not grown in Solano or Marin Counties but I included it because of the variety of colors, naturally dyed, and the quality of the yarn, and it is grown in the Pacific Northwest, which is Closer to Home than many places where wool is grown.

This is one of only two yarns in this show that are not grown in Solano or Marin Counties but I included it because of the variety of colors, naturally dyed, and the quality of the yarn, and it is grown in the Pacific Northwest, which is Closer to Home than many places where wool is grown.

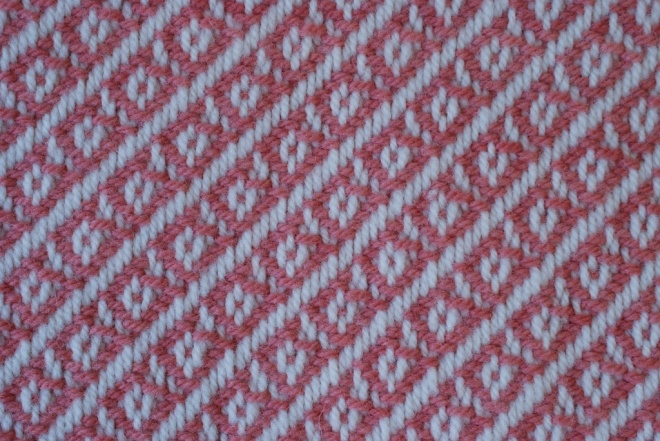

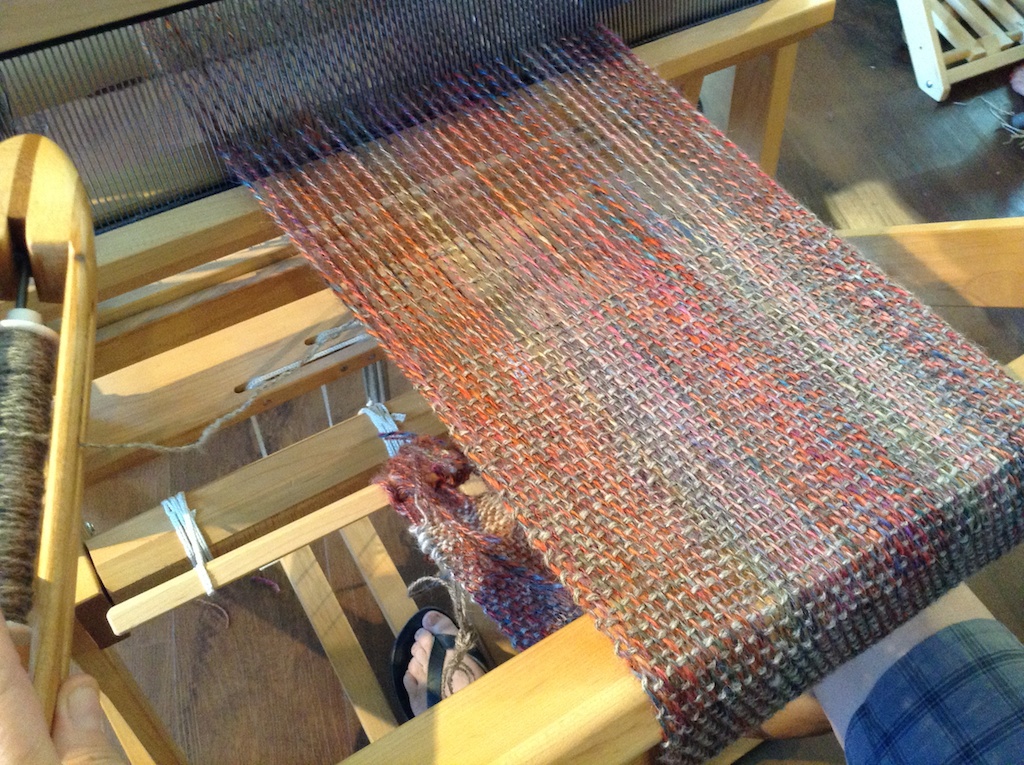

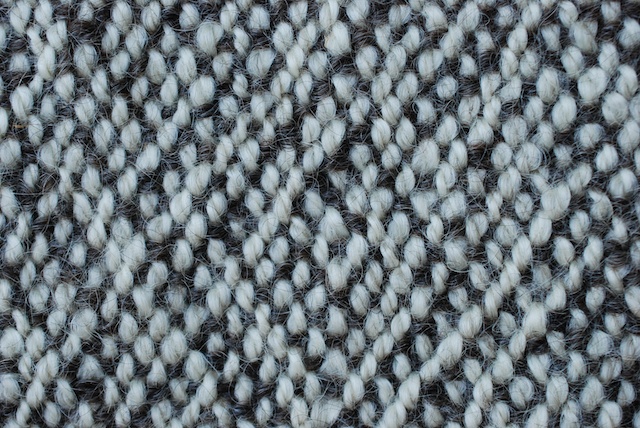

That means that each of the blankets above was woven on the same warp threading in white yarn, but the patterns change by varying the treading and, of course, the color of the weft.

That means that each of the blankets above was woven on the same warp threading in white yarn, but the patterns change by varying the treading and, of course, the color of the weft.

At the end of the warp I just wove in white instead of making it plaid and then I felted the fabric. That made great fabric for pillows.

At the end of the warp I just wove in white instead of making it plaid and then I felted the fabric. That made great fabric for pillows.

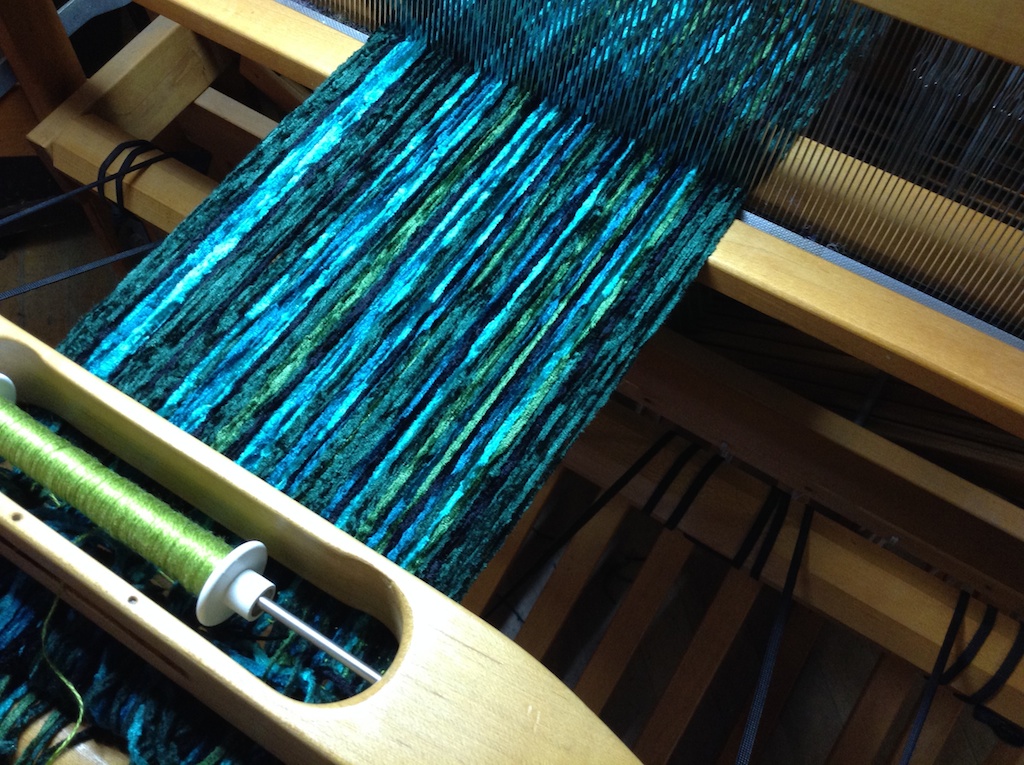

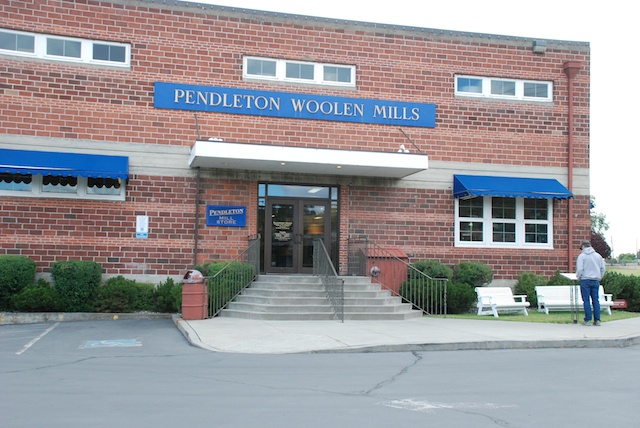

There were about a dozen people there for the tour even at 9 a.m. on a Monday morning. It was interesting to see the workings of the mill but now I have a lot of unanswered questions. We all wore headsets so that we could hear the tour guide over noise of the mill machinery but that meant that there was no opportunity to ask questions while we were walking. And the tour was fast. I would have liked to stop and watch what was going on with each loom. Now that I’m looking at my photos I realize that I have even more questions about what I was seeing. I guess I’ll just have to go back!

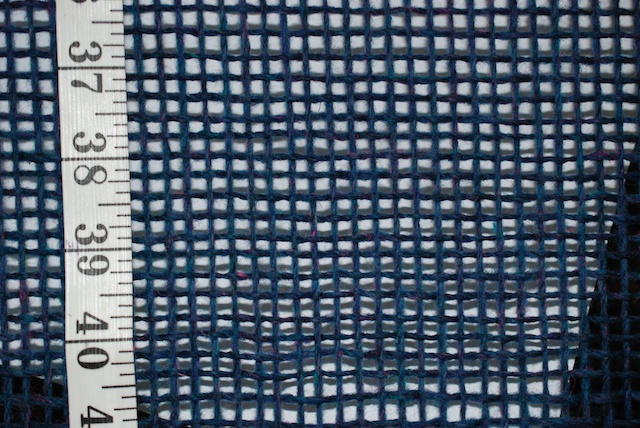

There were about a dozen people there for the tour even at 9 a.m. on a Monday morning. It was interesting to see the workings of the mill but now I have a lot of unanswered questions. We all wore headsets so that we could hear the tour guide over noise of the mill machinery but that meant that there was no opportunity to ask questions while we were walking. And the tour was fast. I would have liked to stop and watch what was going on with each loom. Now that I’m looking at my photos I realize that I have even more questions about what I was seeing. I guess I’ll just have to go back! The Mill uses Rambouillet wool from Oregon and surrounding states and Merino wool from New Zealand and Australia. The wool is scoured in Texas and then comes to Oregon for spinning and weaving. The carding and spinning equipment was on the second floor. That room was quite humid. The guide told us that high humidity lessons the quantity of airborne particles so employees don’t have to wear dust masks. Now I wonder if that is the main reason for the humidity or if it makes carding and spinning more efficient (or both). The photo above shows the carding equipment operating behind plexiglass.

The Mill uses Rambouillet wool from Oregon and surrounding states and Merino wool from New Zealand and Australia. The wool is scoured in Texas and then comes to Oregon for spinning and weaving. The carding and spinning equipment was on the second floor. That room was quite humid. The guide told us that high humidity lessons the quantity of airborne particles so employees don’t have to wear dust masks. Now I wonder if that is the main reason for the humidity or if it makes carding and spinning more efficient (or both). The photo above shows the carding equipment operating behind plexiglass.

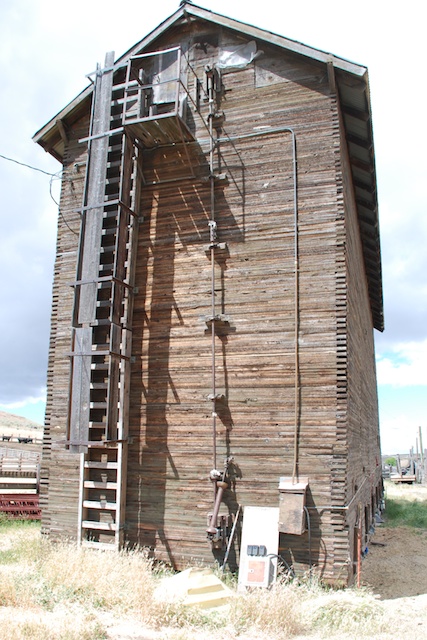

The sheep are gathered at the back of a trailer that is hauled from ranch to ranch with all the gear. They go up the chute with the encouragement of…

The sheep are gathered at the back of a trailer that is hauled from ranch to ranch with all the gear. They go up the chute with the encouragement of…

Here is a view from the other end of the trailer. That sheep in front hangs out for awhile in that position because the other sheep are more likely to go forward if they see a sheep in front of them. Notice how the sheep walk on a raised alleyway while the freshly shorn fleeces are shoved out of the trailer below them.

Here is a view from the other end of the trailer. That sheep in front hangs out for awhile in that position because the other sheep are more likely to go forward if they see a sheep in front of them. Notice how the sheep walk on a raised alleyway while the freshly shorn fleeces are shoved out of the trailer below them.