Here is a blanket that has become one of my favorites to weave.

In the book where I saw this draft it is called Breaks & Recesses. I think I need to come up with a different name.

I have mentioned before how much a woven piece changes after it is has been properly finished. In the case of wool that means wet-finishing or some degree of fulling. When a piece is fulled the individual threads become less distinct as the wool fibers catch on each other and the piece becomes cloth instead of a bunch of separate threads. (Fulling is an irreversible process that needs to be controlled–picture a wool sweater that goes through the washing machine and dryer.)

This is a dramatic example. The blanket on the right is the same draft and using the same yarn, but it has not been finished yet. This yarn is one that was mill-spun of wool from sheep at the place where I used to go for sheepdog training. The yarn feels harsh and oily, but it softens beautifully when fulled.

A custom blanket customer saw a similar blanket and wanted me to weave her a queen size blanket using this pattern. “Sure”, I said. “No problem.”

I use double weave to weave a queen (84 x 90) blanket on a 60″ wide loom. That means that I weave two layers at a time with a fold on one side. I have to allow for take-up and shrinkage (part of that is the fulling I described) so this blanket measured 54″ wide on the loom (double–opened up that would be 108″) and I planned to weave 100″ in length. A lot of this is educated guessing based on previous similar projects.

This pattern is woven on 8 shafts. To weave a double width blanket I used 16 shafts, 8 for each layer. First I had to figure out that part. None of this will make sense if you are not a weaver and I didn’t intend for this post to be an explanation of all the steps. One of these days maybe I’ll do that, but not now.

This looks nothing like the pattern in the finished blanket. That’s because in this draft every other horizontal and vertical line is the opposite layer (odd numbers are the top and even numbers are the bottom). When I buy new software it will be something that will show me the top and bottom layers.

When I finally started weaving the blanket I knew that something wasn’t right, but I had a hard time figuring out exactly what it was. I used a mirror to see the lower layer but I had to go back to the book and the computer to see that I had reversed some of the squares in the draft.

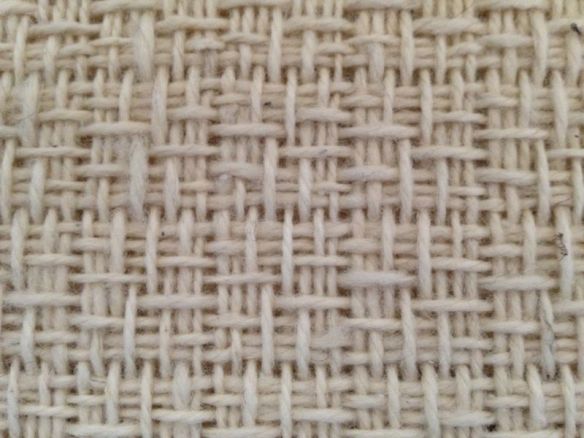

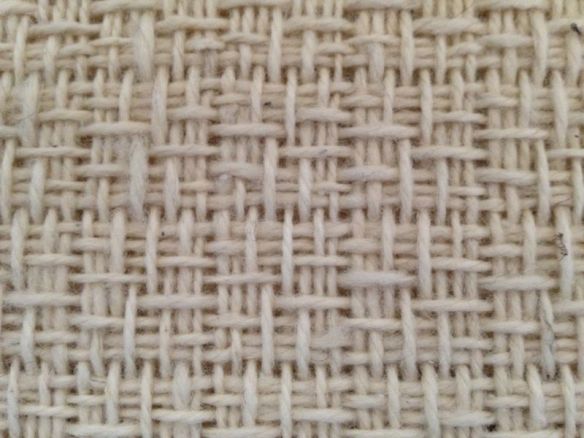

Here is a close-up of the top layer as I was weaving.

This is what the computer looks like as I am weaving. I have what is called a compu-dobby and the computer drives which shafts lift, although I do all the work.

See the shuttle at the other side of the loom?

As I step on the treadle certain shafts lift so that the shuttle can carry the yarn in between the threads.

This is after the shuttle has gone from left to right and is now on the other side.

This is a view of the left side where I can separate the layers. The fold is on the right.

I finished weaving this blanket today and am working on correcting a few errors. Then I will have to crochet the edges before I full it. I should take photos of these processes and report back.

This is a stack of 19 blankets that I just finished. There is still warp on the loom, but I needed to get these off the loom (and I needed to give my shoulder a break–now it’s the right one giving me trouble). My daughter will choose one when she is here this week and the rest will go to The Artery for sale. They are also on my website.

This is a stack of 19 blankets that I just finished. There is still warp on the loom, but I needed to get these off the loom (and I needed to give my shoulder a break–now it’s the right one giving me trouble). My daughter will choose one when she is here this week and the rest will go to The Artery for sale. They are also on my website.

Camo anyone?

Camo anyone?

And here is the floor behind the loom.

And here is the floor behind the loom.