Three days in a row with a blog post! I’m on a roll.

I didn’t write about my newest yarn because I wanted to have all the details. Here it is, although not on the website yet.

I shared this photo in a previous post. I just picked up the yarn from Valley Oak Mill a week or two ago. This is the last of the 2023 Jacob fiber.

The first thing I need to do before planning a weaving project and before listing the yarn for sale is evaluate the yarn. Measuring wraps/inch (WPI) is one step.

Look at what I finally figured out–how to put photos side-by-side. It only took 20 minutes of trial and error and I don’t know if I can do it again. Now if I could just figure out how to change the size of the spaces .

The point of this is to show the wpi measurements for the same yarn before and after wetting. The yarn on the left is wound straight from the cone. The sample yarn on the right shows the WPI after the yarn has “bloomed”. I soak the skeins in water for about five minutes and then spin them out and let them dry. It is important to plan a project based on what the yarn will look like when the knitted or woven or crocheted project is wet finished. In the case of all these yarns they measured 17 WPI when wound from the cone and 12 WPI after washing. That’s a big difference.

Here is how the black yarn looks.

Here is this yarn on the loom. I sett it at 8 epi (ends per inch) based on the 12 WPI measurement. It looks very open but remember that the yarn is under tension on the loom and it has not been wet finished. It will bloom as in the photos above.

The stars appear due to alternating 6 dark threads and 6 light threads in warp and weft AND the weave structure. Without the two colors you wouldn’t see stars and without the weave structure (tie-up and treadling) you would see a plaid. There is a trick to weaving this without cutting the yarn every time you change color and keeping the selvedges neat. I put boxes at the right height at each side of the loom and rest the unused shuttle there where I can reach under the yarn when I catch the active shuttle for six picks.

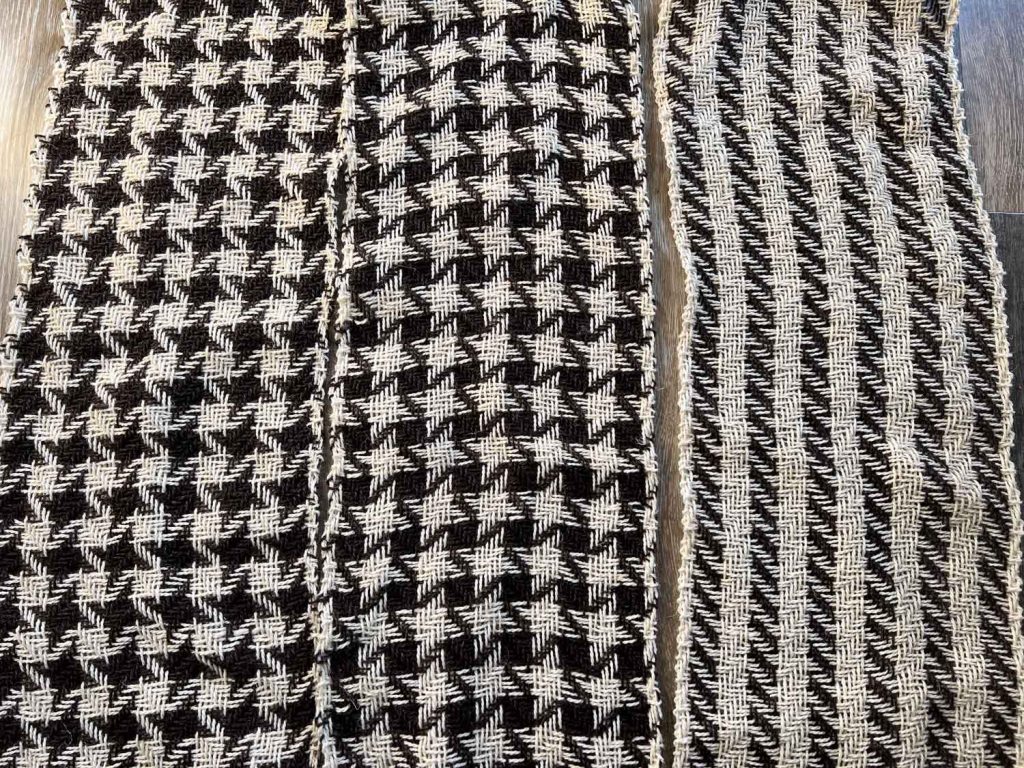

This is how the scarves look off the loom, not yet wet finished. The stars are black on one side of the scarf and white on the other.

Here are the finished scarves. I have two of the stars scarves and one of the stripes. They may be sold this weekend but I can make more before Christmas. I wonder if I should try other colors. I could use the Timm Ranch naturally dyed yarn or Ashford yarn. I’d like to weave some in cotton as well. Too many ideas, too little time. If you’d like one let me know soon.