I always tell students that unless you are using the exact same yarn in the exact same way that you have used it before, then your project is an experiment. Call it a full-size sample if you want to.

I’m OK with that. Who wants to do the same thing over and over? This is my latest warp. I wound 13 yards of mixed Solano County wool yarns. These are yarns that I have had spun in the last few years from the Timm Ranch, Anderson Ranch, and my own flock. Most were dyed with black walnuts–it’s amazing the range of colors you can get when you use a black walnut dye pot over and over…and over. It keeps on giving color. Look at the range of browns in the photo below.

This is my latest warp. I wound 13 yards of mixed Solano County wool yarns. These are yarns that I have had spun in the last few years from the Timm Ranch, Anderson Ranch, and my own flock. Most were dyed with black walnuts–it’s amazing the range of colors you can get when you use a black walnut dye pot over and over…and over. It keeps on giving color. Look at the range of browns in the photo below. The other thing to notice about this photo is that the last piece woven on it is so much narrower than the others. This was the fourth shawl on the warp. The one before this one is a different weave structure (advancing twill treadling), but the first two are the same structure as the fourth one. The only difference is the weft yarn. The first three shawls were woven with 2015 Timm Ranch yarn on cones. The weft for the fourth shawl is 2016 Timm Ranch yarn that has been dyed. This is a perfect example of the difference that “finishing” yarn can make.

The other thing to notice about this photo is that the last piece woven on it is so much narrower than the others. This was the fourth shawl on the warp. The one before this one is a different weave structure (advancing twill treadling), but the first two are the same structure as the fourth one. The only difference is the weft yarn. The first three shawls were woven with 2015 Timm Ranch yarn on cones. The weft for the fourth shawl is 2016 Timm Ranch yarn that has been dyed. This is a perfect example of the difference that “finishing” yarn can make.  This is one of the previous batch of shawls. It is mostly Jacob yarn but the weft is last year’s Timm Ranch/Jacob blend used from a cone without washing. In this case the width of the warp in the reed was 30″ with a sett of 6 epi. That is very open but when wet finished the shawl is lightweight and has great drape. However, the finished width is only about 20″ (33% draw-in and shrinkage). So I sett the brown warp the same at 6 epi but started with a 39″ wide warp.

This is one of the previous batch of shawls. It is mostly Jacob yarn but the weft is last year’s Timm Ranch/Jacob blend used from a cone without washing. In this case the width of the warp in the reed was 30″ with a sett of 6 epi. That is very open but when wet finished the shawl is lightweight and has great drape. However, the finished width is only about 20″ (33% draw-in and shrinkage). So I sett the brown warp the same at 6 epi but started with a 39″ wide warp.

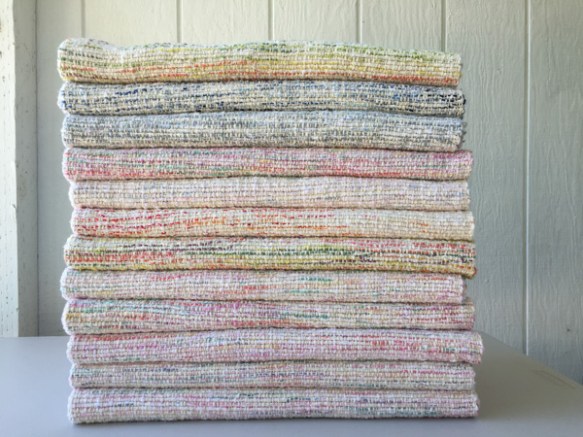

Here are the shawls from the brown warp after wet finishing. That one that was so much narrower on the cloth beam? That is the one that is a little wider here. It is now 27″ wide (30% draw-in and shrinkage). The shawl in the same pattern but woven with the white weft is 26″ wide (33% draw-in and shrinkage). The difference between width in the reed and the finished piece isn’t much, but the photos show the dramatic difference in how the yarn behaves while it is woven.

Here are the shawls from the brown warp after wet finishing. That one that was so much narrower on the cloth beam? That is the one that is a little wider here. It is now 27″ wide (30% draw-in and shrinkage). The shawl in the same pattern but woven with the white weft is 26″ wide (33% draw-in and shrinkage). The difference between width in the reed and the finished piece isn’t much, but the photos show the dramatic difference in how the yarn behaves while it is woven.  Here is a before and after photo. The bottom shawl has been wet finished. The top one is the same weft yarn and same pattern, but has not been washed. Look at the very first photo in this post. You can see how wide open the yarns are. Off the loom they are a little closer, but that looks nothing like it will when finished.

Here is a before and after photo. The bottom shawl has been wet finished. The top one is the same weft yarn and same pattern, but has not been washed. Look at the very first photo in this post. You can see how wide open the yarns are. Off the loom they are a little closer, but that looks nothing like it will when finished.  An example of trying to take product photos with the help of a Border Collie.

An example of trying to take product photos with the help of a Border Collie. Here is one of the final product photos. I noticed a surprise. I started to see a purple cast to one of the warp yarns. At first I thought that I just hadn’t noticed that shade inside while I was weaving. I tried to convince myself that it was still brown.

Here is one of the final product photos. I noticed a surprise. I started to see a purple cast to one of the warp yarns. At first I thought that I just hadn’t noticed that shade inside while I was weaving. I tried to convince myself that it was still brown. Do you see it here?

Do you see it here?  Another photo of one not washed (no purple) and one washed. I lined up the same warp threads in these two pieces.

Another photo of one not washed (no purple) and one washed. I lined up the same warp threads in these two pieces.  Depending on the light setting in the photo (and maybe your monitor) you may see it more clearly in one of these other photos.

Depending on the light setting in the photo (and maybe your monitor) you may see it more clearly in one of these other photos. In person it is clearly visible, although it doesn’t stand out.

In person it is clearly visible, although it doesn’t stand out.

The answer…that was a yarn dyed with mushrooms from a friend. It must have been rhe soap that caused the shift in color. I love it. Lisa, what is the name of that?

This is a selection of the BFL yarn in fingering weight. That’s a light weight yarn often used for knitting socks. You might wonder how purple and pink fit into cat and dog colors. The purple is called “cheshire cat”. I still didn’t understand how that fit until I googled “cheshire cat” and found that Disney’s version of the cheshire cat is indeed purple.

This is a selection of the BFL yarn in fingering weight. That’s a light weight yarn often used for knitting socks. You might wonder how purple and pink fit into cat and dog colors. The purple is called “cheshire cat”. I still didn’t understand how that fit until I googled “cheshire cat” and found that Disney’s version of the cheshire cat is indeed purple. What about this one? It’s called Kitten Nose Pink.

What about this one? It’s called Kitten Nose Pink. It’s easy to see the calico here.

It’s easy to see the calico here. These yarns are Merino fingering weight. They come in the same colorways. I bought a variety of each because I couldn’t get them all.

These yarns are Merino fingering weight. They come in the same colorways. I bought a variety of each because I couldn’t get them all. Here is my first project using one of the yarns. One skein will easily make a scarf.

Here is my first project using one of the yarns. One skein will easily make a scarf. I also tried the Zoom Loom to see how they looked. The yarn is too thin to use singly, but doubled it’s great!

I also tried the Zoom Loom to see how they looked. The yarn is too thin to use singly, but doubled it’s great! I was OK for Fire. I had wound the two white/off-white warps but wanted to start with something else to try out the colors.

I was OK for Fire. I had wound the two white/off-white warps but wanted to start with something else to try out the colors. I still have some warps leftover from my

I still have some warps leftover from my  Now was the time. I started with yellow but it didn’t cover the colors very well so this warp went to oranges and reds.

Now was the time. I started with yellow but it didn’t cover the colors very well so this warp went to oranges and reds. That was the “practice” warp. Now it was time for the “real” one and I decided to use just these colors.

That was the “practice” warp. Now it was time for the “real” one and I decided to use just these colors. You can see the yarns that I used weren’t all the same because I didn’t have enough of any one shade. Here is where my photo documentary of the process has holes. This was a cold, damp day. I was bundled up in overalls and Carhart jacket and wool layers. I had footwarmers in my boots but I had to keep switching from warm gloves to rubber gloves, neither of which lent themselves to taking lots of photos. And it was getting late in the day and I was starting to lose the light. So no more photos of these warps after dyeing.

You can see the yarns that I used weren’t all the same because I didn’t have enough of any one shade. Here is where my photo documentary of the process has holes. This was a cold, damp day. I was bundled up in overalls and Carhart jacket and wool layers. I had footwarmers in my boots but I had to keep switching from warm gloves to rubber gloves, neither of which lent themselves to taking lots of photos. And it was getting late in the day and I was starting to lose the light. So no more photos of these warps after dyeing.  I wasn’t satisfied with the dye job on the white warp so I wound another but this time used yellow yarns because I didn’t have anymore white. I dyed this in those same colors.

I wasn’t satisfied with the dye job on the white warp so I wound another but this time used yellow yarns because I didn’t have anymore white. I dyed this in those same colors. Dona was at the shop the day I was trying to get these warps to dry. She took this photo of them hanging near the heater.

Dona was at the shop the day I was trying to get these warps to dry. She took this photo of them hanging near the heater.  Back to the dye day. These were the blues. It was getting late so not many more photos.

Back to the dye day. These were the blues. It was getting late so not many more photos. Here is one of the Mountain Sky warps.

Here is one of the Mountain Sky warps.  I wove seven Fire scarves (two were finished the night before the show so aren’t photographed here) and five Mountain Sky scarves.

I wove seven Fire scarves (two were finished the night before the show so aren’t photographed here) and five Mountain Sky scarves.

I will do another post of how the Artery show looks.

I will do another post of how the Artery show looks.

This is one of only two yarns in this show that are not grown in Solano or Marin Counties but I included it because of the variety of colors, naturally dyed, and the quality of the yarn, and it is grown in the Pacific Northwest, which is Closer to Home than many places where wool is grown.

This is one of only two yarns in this show that are not grown in Solano or Marin Counties but I included it because of the variety of colors, naturally dyed, and the quality of the yarn, and it is grown in the Pacific Northwest, which is Closer to Home than many places where wool is grown.

That means that each of the blankets above was woven on the same warp threading in white yarn, but the patterns change by varying the treading and, of course, the color of the weft.

That means that each of the blankets above was woven on the same warp threading in white yarn, but the patterns change by varying the treading and, of course, the color of the weft.

At the end of the warp I just wove in white instead of making it plaid and then I felted the fabric. That made great fabric for pillows.

At the end of the warp I just wove in white instead of making it plaid and then I felted the fabric. That made great fabric for pillows.