I woke up at 5 and thought of things that need to be done. No point in staying in bed.

Rewrite minutes from Tuesday evening’s Artery Board meeting. ✓

Make one more 15′ length of e-net fence so I can switch sheep to another paddock. ✓

Walk across the road with Ginny. ✓

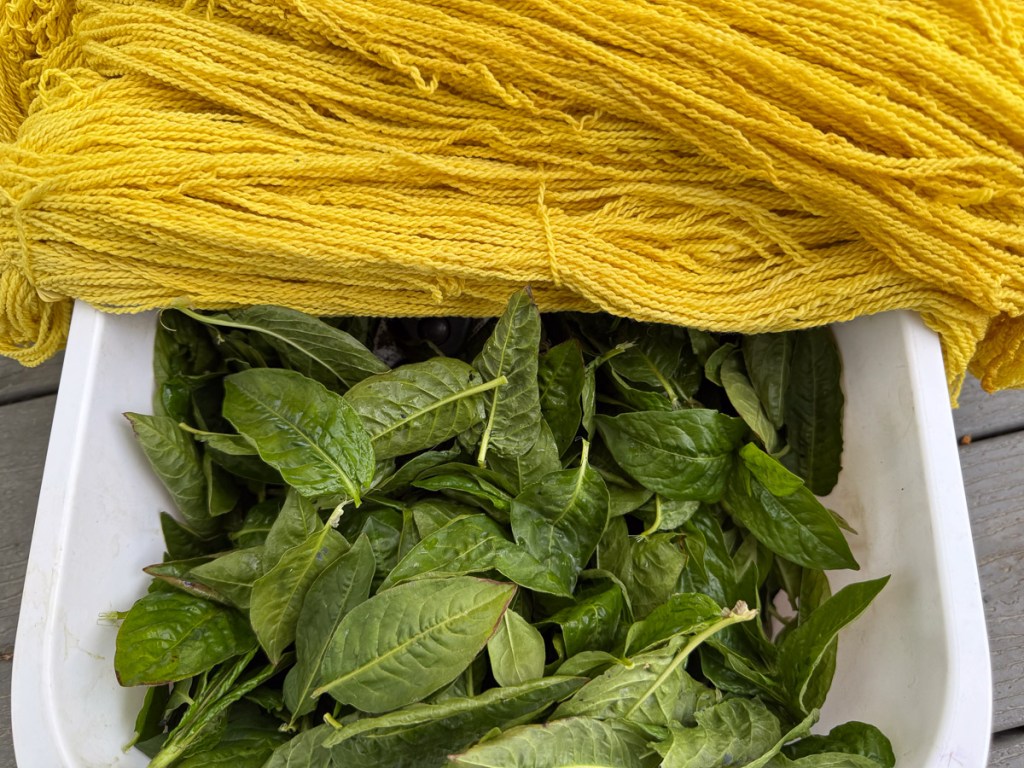

Do a fresh-leaf indigo dye bath to over dye the weld-dyed yellow yarn. ✓

Here are the photos to accompany that check list:

There are 3-wire electric fences every 60 feet in the south pasture. These are charged by attaching to a hot wire at the south border fence. I need to connect a 15′ net fence from that hot wire to these north-south fences. My goal was to have all electric net fences for blocking off the 60′ spaces and the 15′ connection fences in place and not have to move those lengths of fence every time I switch to a new paddock. I have finally accomplished that goal with this morning’s 15′ fence! (I think–maybe I need one more.)

Another accomplishment is to organize and label what’s left. There are three fences that will make up one long north-south fence if I decide to split the 60′ paddock in half lengthwise. The other two bags are leftover but still useable portions of net fence.

Time for a walk Across the Road. This is for Ginny’s mental benefit and for mine. If I go in the morning then all day I can remember that I got at least a little exercise.

This tractor was parked near the hayfield. That tire is taller than I am!

A view of the new paddock from the main road coming back from our walk.

Indigo in the garden.

I harvested about a pound of leaves to overdye the yellow yarn I dyed with weld the day before. I dye with fresh leaves using ice water and a blender. After that dye bath was in place I could move on to something else.

What is the plan for the afternoon?

Make more horn buttons ✓

Thread the hemp warp that is on one of the looms. ✓

Photograph all the unfinished pieces for yesterday’s blog post. ✓

I cut more buttons. The next step is to drill holes and then sand. I found some that already had holes but I had not sanded them. Those are in the three cups at the bottom. I keep track of buttons that will match by keeping all from one horn together through the process. I sanded all those that already had holes in them, but still need to drill the others.

While I was working in the barn on buttons we had a hay delivery. This is 88 bales that need to go in the barn.

I took the indigo-dyed yarn out of the bucket and hung it up to drip. When I’m finished here I’ll cut apart the bundled skeins so they can dry better. The yellow one is what the green ones looked like before putting in the indigo. The blue yarn was white yarn in the same bucket.

I went to one of the looms in the shop to thread my space-dyed hemp yarn and finished about chore time. Now it’s ready to weave. That is on today’s list, along with sanding those buttons.

Dottie brought a car-load of supplies. She put indigo in a tea strainer and we watched the water turn color. We also noticed a metallic sheen on the water and weren’t sure what to do about that. We forged ahead…

Dottie brought a car-load of supplies. She put indigo in a tea strainer and we watched the water turn color. We also noticed a metallic sheen on the water and weren’t sure what to do about that. We forged ahead… …sampling with cotton fabric that Dottie had brought with her. The metallic stuff showed up on the fabric but it seemed that we could wipe it off easily.

…sampling with cotton fabric that Dottie had brought with her. The metallic stuff showed up on the fabric but it seemed that we could wipe it off easily. So we went ahead with the dress. When dyeing with indigo you don’t want to stir up the dye bath because indigo dyeing relies on a chemical reaction as the fabric comes out of the dye and reacts with oxygen. If you introduce oxygen into the dye bath you lose some of the effectiveness of the indigo.

So we went ahead with the dress. When dyeing with indigo you don’t want to stir up the dye bath because indigo dyeing relies on a chemical reaction as the fabric comes out of the dye and reacts with oxygen. If you introduce oxygen into the dye bath you lose some of the effectiveness of the indigo. When you bring something out of an indigo bath it is green at first.

When you bring something out of an indigo bath it is green at first. As it reacts it turns blue. Usually you rely on several dips to darken the color, but this one came out fairly dark the first time. However, we saw unevenly dyed areas where I had been too careful about lowering the dress into the bath and the dye didn’t get into the folds. There was also that metallic stuff in spots. I decided to hose the dress off (no pictures at this point) and see what it looked like. Not good. Very splotchy and not in a good way. So I tried again, this time stirring the dress in the pot with my hands. It was more important to get an even dye job than to save the dye bath for later.

As it reacts it turns blue. Usually you rely on several dips to darken the color, but this one came out fairly dark the first time. However, we saw unevenly dyed areas where I had been too careful about lowering the dress into the bath and the dye didn’t get into the folds. There was also that metallic stuff in spots. I decided to hose the dress off (no pictures at this point) and see what it looked like. Not good. Very splotchy and not in a good way. So I tried again, this time stirring the dress in the pot with my hands. It was more important to get an even dye job than to save the dye bath for later. Here is the final product. But we weren’t done. There was another step and that was a surprise to me. First though the dress had to be completely dry, so that step was going to have to wait until later.

Here is the final product. But we weren’t done. There was another step and that was a surprise to me. First though the dress had to be completely dry, so that step was going to have to wait until later. No, one of us didn’t grow an extra hand. Dottie came with a friend who took some of these photos while we were working.

No, one of us didn’t grow an extra hand. Dottie came with a friend who took some of these photos while we were working.