Before the last couple of lamb posts I started to take a look back at weaving in 2023. Here is the next about weaving

Warp #1308 was baby blankets. I need to get another baby blanket warp on the loom because I’m almost out. Do you know that one of the first things I wove was a baby blanket for my son who is now 43? I have been weaving pretty much the same blankets all this time. If people still like them I guess that’s OK. I have a lot of other ideas though. Just no time.

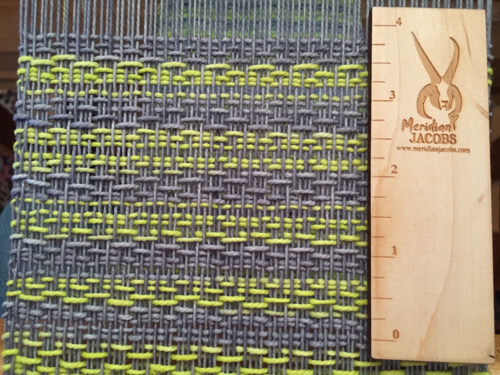

Warp # 1311 was for samples using the yarn I got back from one of the mills. The samples are Jacob warp with Jacob and Timm Ranch weft at two different setts. The photo on the left is before washing and the right is after washing. That is where differences in take-up and draw-in really show up.

These samples were all from one warp but resleyed to weave at 15 epi, 18 epi, and 24 epi. I used these for a Yarn Lab article for the Jan/Feb 2024 Handwoven magazine.

This is one of several clasped warp scarves and shawls I wove. They will be in an upcoming issue of Handwoven.

Warp 1326 was Timm Ranch yarn and I wove two shawls, one with indigo-dyed weft, and one with 3 supplementary warps to create the design.

The next warp is Jacob wool. I really like how the two sides of this pattern are so different.

This is Warp 1328 with 14 blankets. I weave these on my 60″ wide AVL production loom.

They look a little better when finished. Some of these are on the website now (here is one). Some are Year to Remember blankets that were custom orders.

This is another clasped warp scarf using Timm Ranch wool that I dyed with homegrown indigo.

Warp 1337 on the loom. This is Timm Ranch warp and Jacob weft.

I wove enough for four pieces and made two into mobius shawls.

So many ideas and so little time. Back to the barn to feed lambs now.

Here is a close-up.

Here is a close-up.