I number all my warps (except for the ones I forget to put in my notebook like some of the rigid heddle projects). Someday I’ll have to look for the notebook with #1, although that wouldn’t be truly #1–it would be the first one I recorded. I think that notebook is here somewhere.

The first one this year was #1351. The notebook page says 12-26-2023, but that would be when I started winding warp. I wove most of the ten blankets in 2024. This photo is two Year to Remember blankets. The one on the left was a custom blanket, commemorating the recipient’s wedding anniversary.

This Year to Remember blanket (Vacaville, 2023) is woven with yarn I dyed using plant material growing here. It is still available on the website.

One of my favorite patterns, also woven on this warp using gray Jacob yarn for weft.

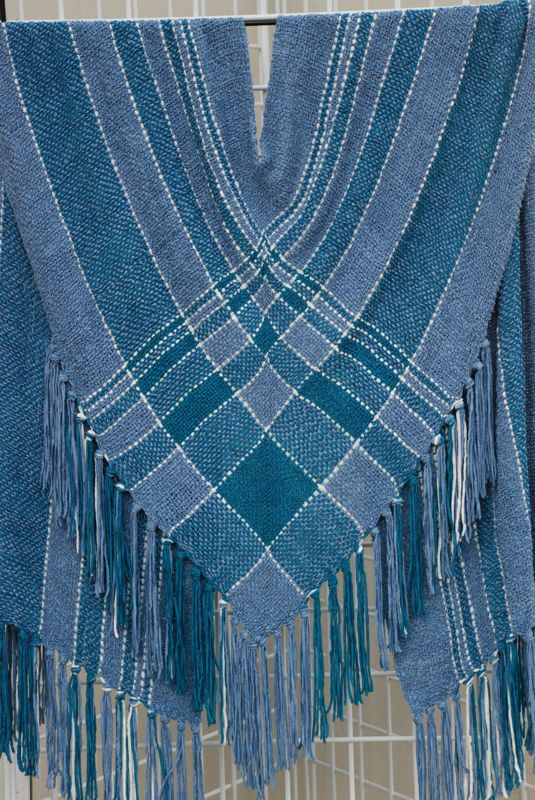

I wove several v-shawls in 2024. The one on the left is still for sale here.

Warp #1387 went on the loom in July, but I didn’t finish the last blanket until December. I get distracted by weaving on other looms and the rest of life going on around me. This photo shows how each weft yarn may behave differently. Some yarns have more elasticity than others, either due to the type of wool or whether or not they have been naturally dyed. The warp and all the naturally dyed yarns are Timm Ranch wool from various years.

Here is that warp off the loom. The blue weft yarn was naturally dyed with my home-grown indigo. The brown yarns are mostly dyed with walnut hulls. Yarns on the left are Ashford DK.

Finished indigo and walnut hull blankets.

The last warp of the year was #1404, a warp for three chenille shawls. This is the first piece off the loom in the process of twisting fringe. This warp is still on the loom with two more shawls to weave. I had wanted to get at least one off to get it to the Artery before the last couple of shopping days before Christmas.

Warp # 1403 went on the loom before the chenille warp, and I finished it just in time for our family Christmas on the 27th. There are ten hemp towels.

There are two colors in the warp and a different weft color in most of the towels.

Another favorite this year was a chenille warp. I wove two rectangular shawls and this piece that is sewn to leave a neck hole and be worn over the shoulders sort of like a poncho. I will put this on the website soon.