What have I been doing all week? Way too much to write down and maybe not all that interesting. But I’m so busy that although I’m always taking photos and thinking of good blog posts I just haven’t had time.

Here are bits and pieces of this week.

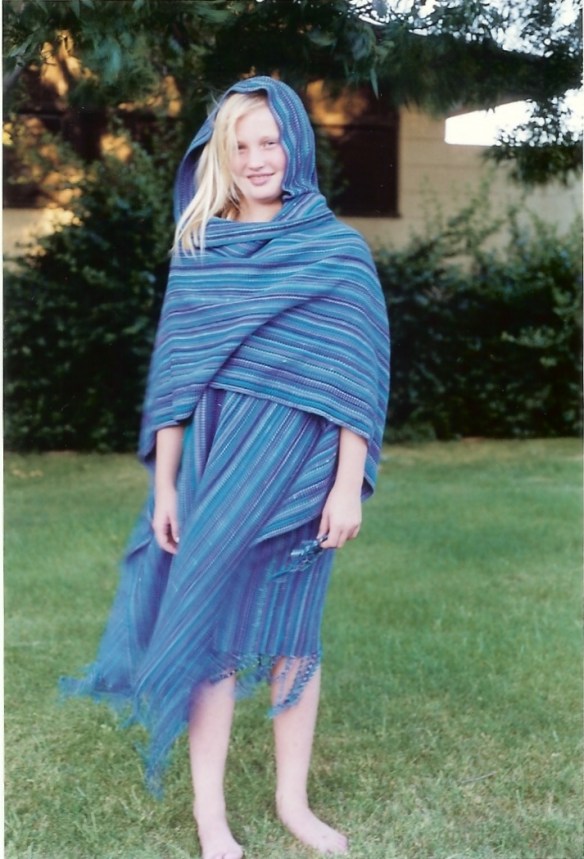

I finally wove some more baby blankets. I have customers waiting. After I took the blankets off the loom I realized that I had a lot of skipped threads along the left side of many blankets. I know why–has to do with combining 7 threads as one in the warp and trying to use 2 threads wound together on the pirn with a fly-shuttle. Just enough drag on the shuttle to cause it to catch the warp threads. AHHHH. That means a lot of fixing. My $/hour just went WAY down. Here are some of the 17 blankets.

These blankets will be on my website after I get better photos. That’s another thing I spent time on. I tried in the sun and in the shade and none of the photos were very good. Back to the drawing board.

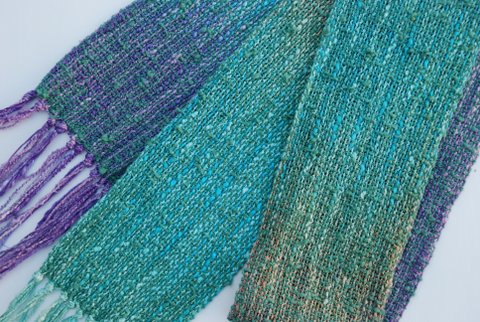

I have projects on three looms right now. Two are for the November show at the Artery. One is for my friend, Irene, owner of Cotton Clouds. That project will be a surprise, but here is a preview:

14 carat gold thread–use sparingly!

This is more of the project. All of these yarns are going into the warp!

In the meantime there are sheep things going on. Savor, one of the yearling rams, had been with a group of ewes and I needed to put him somewhere temporarily. I didn’t want to put him back with his buddy, Tioga, because I figured that they’d have to fight it out first and I can’t deal with that right now. So I gathered up the ram lambs that are left and put them all together. Usually the lambs bow down to the older and stronger ram and leave him alone. There is posturing, but if they know what’s good for them they won’t antagonize the big guy.

At first I thought it would be OK.

They look friendly enough, but finally Savor started threatening one of them more seriously. It happened to be a ram lamb who is already sold for breeding but hasn’t gone to his new home yet. I needed to separate them because I didn’t want to take a chance.

The ewes were all looking hopeful that they would get a chance to mingle with the rams. “We’re ready! Come hither!” Notice the double fence.

Last but not least–someone in this house has no problem taking naps: