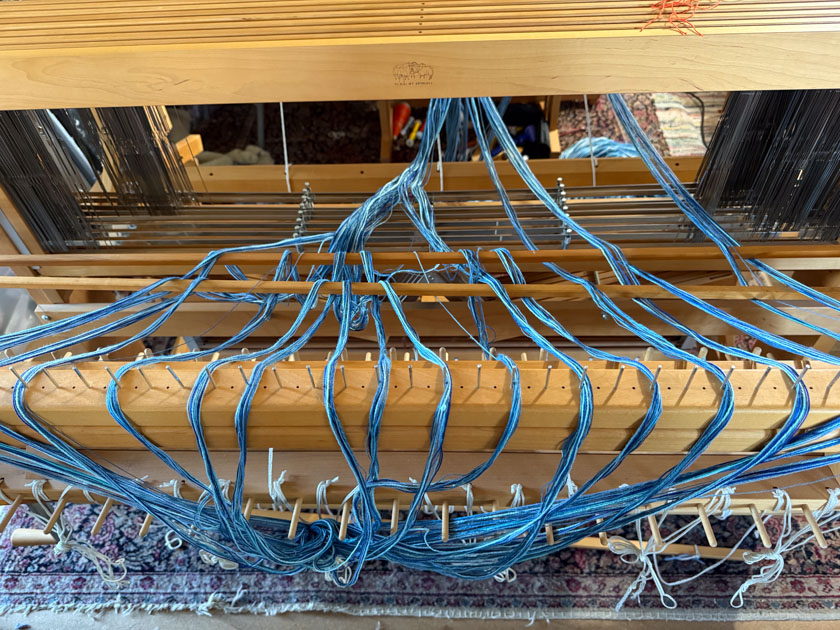

In the 2025 Weaving Recap blog post I included a photo of baby blankets still on the loom and said that warp had been on the loom since October. How about August? That’s what I found when I looked back for photos of warping this loom. Don’t ask me why I decided to wind a warp this way, but it seemed like a good idea at the time.

I used a paddle so each pass was four threads and I made a 26 yard warp.

I have wound 20 or 30 yard warps sectionally using the traditional method for sectional warping or using the AVL warping wheel. But I got this idea of using two warping boards and thought, why not?

I had to wind two bouts to accommodate all the yarn. My goal was to use up odds and ends of cones of yarn so the second warp. That meant the second warp would be different from the first, but I wanted the colors distributed throughout. I spaced the first one out in the raddle.

Then I added the second warp in the empty spaces.

I used two end sticks instead of trying to intersperse the two bouts onto one stick.

This looked good.

This side was a little messier, but it all worked out eventually.

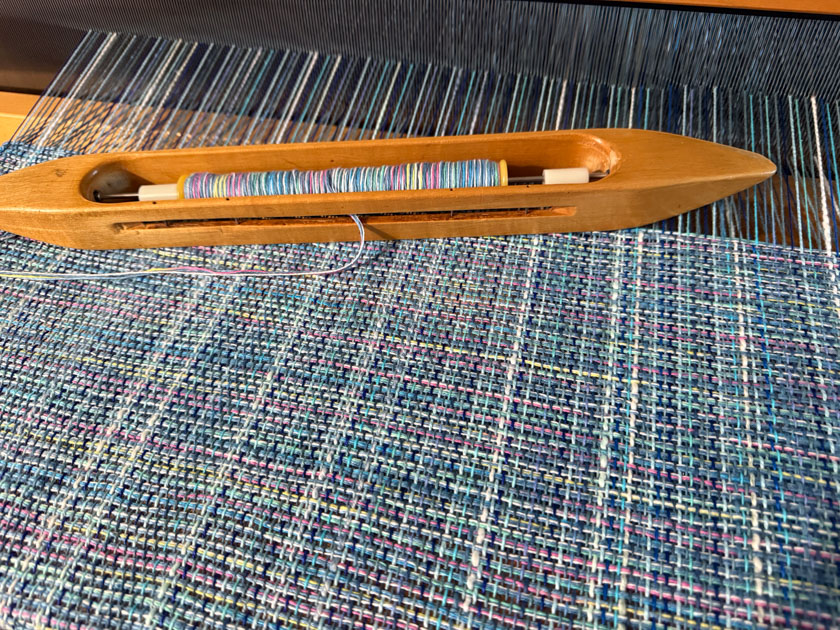

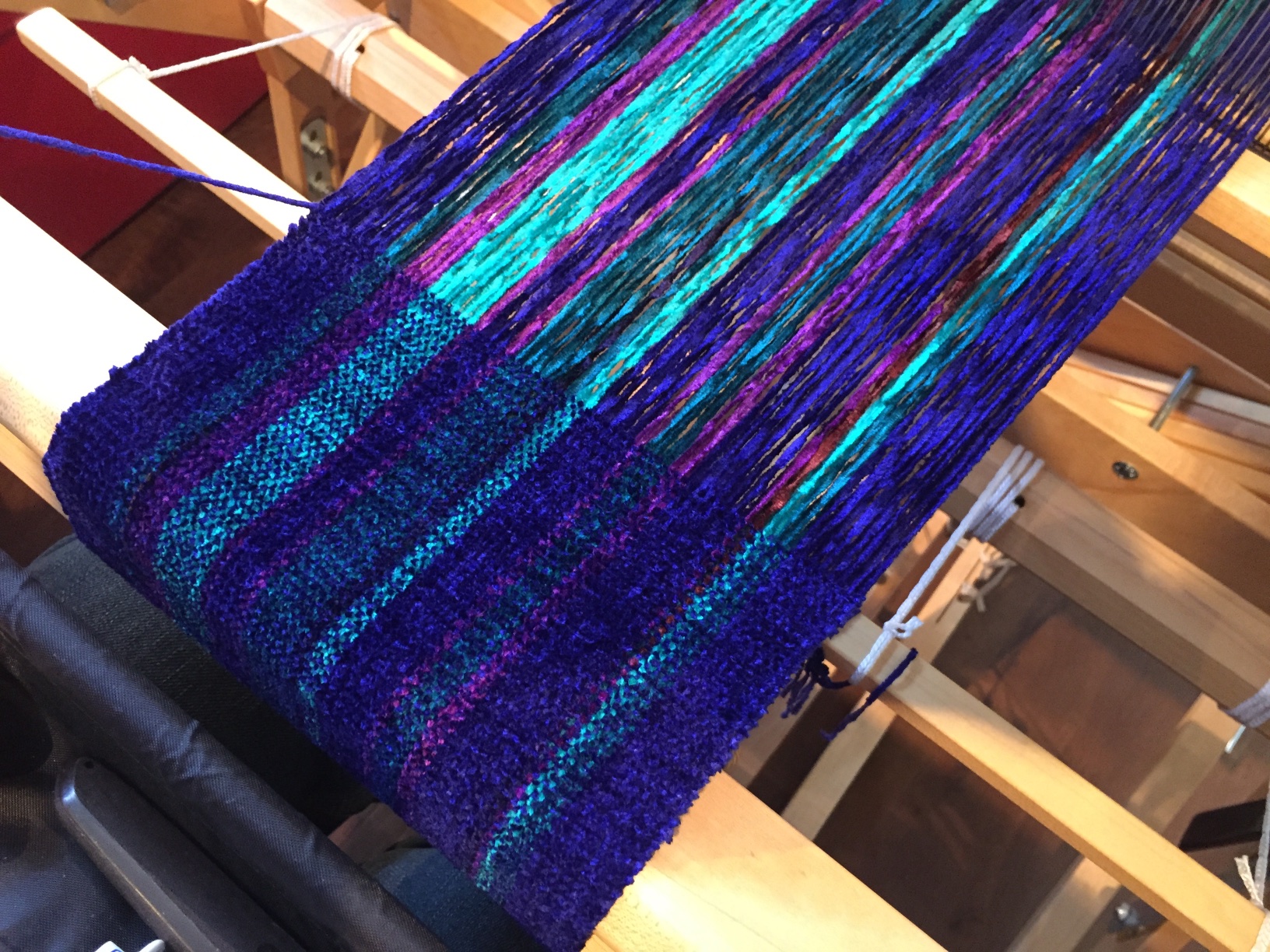

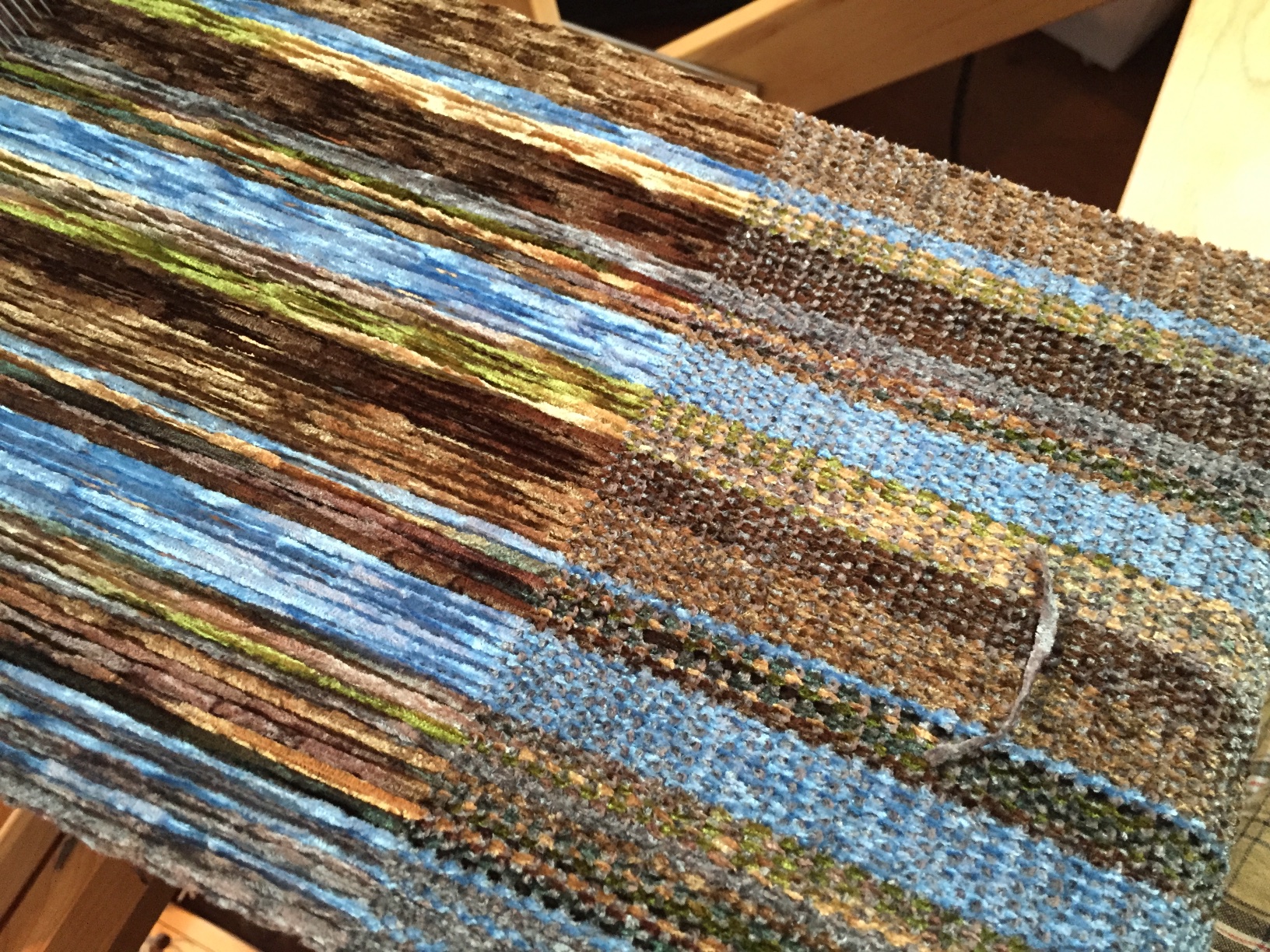

Weaving in progress.

I had an order for blankets so I cut some off the loom early and didn’t get back to that warp until recently.

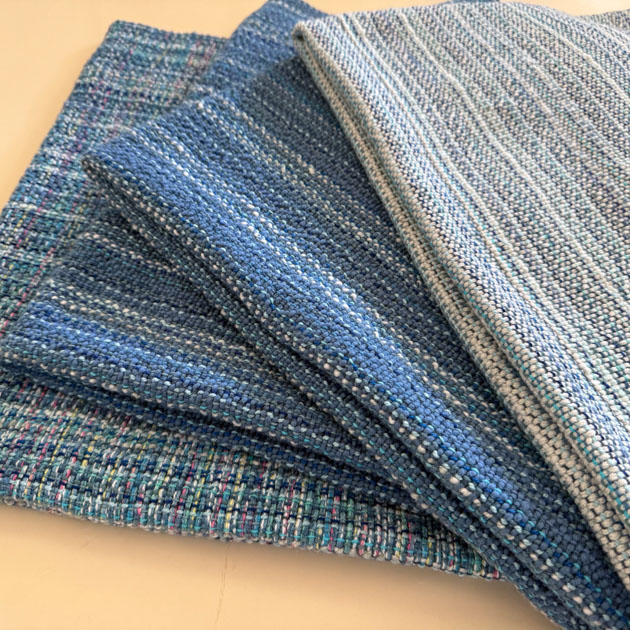

This is the warp I just finished before cutting anything apart. People always ask how long does it take to weave a piece. There are processes other than weaving that go into completing a project. In this case all blankets were machine stitched at each end before cutting them apart. Then some were hemmed. All are washed and then I sew on my label and add the hangtag.

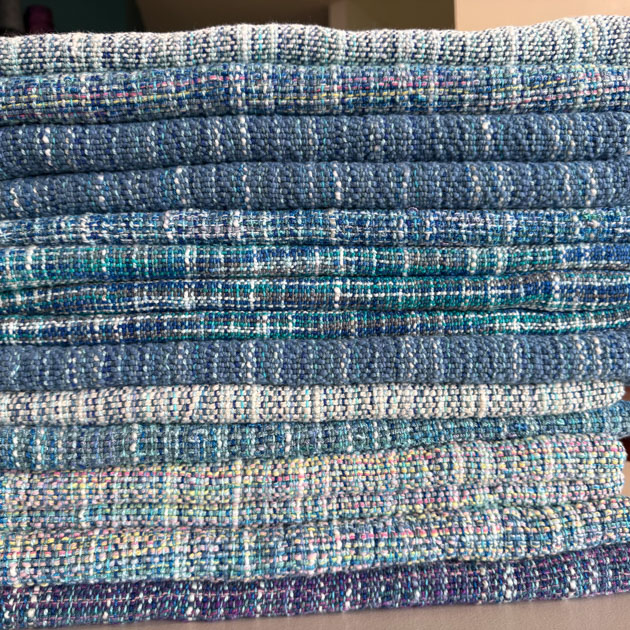

There are multiples of some of these blankets. Those are stacked with two or three.

Another view of all the blankets. You can find some of these blankets on my website and here at the farm store. Others are at The Artery and some are on the Artery’s webstore (local pick-up for those right now). Next up will be a white warp so I can have a variety of colors.

I didn’t list this one because right now I can’t find it. That may mean it is at the Artery. Or did I sell it? This is what I mean be trying to keep track. I’m not doing very well with that.

I didn’t list this one because right now I can’t find it. That may mean it is at the Artery. Or did I sell it? This is what I mean be trying to keep track. I’m not doing very well with that. My niece was nice enough to model for me at Thanksgiving.

My niece was nice enough to model for me at Thanksgiving.

Photobombing brother.

Photobombing brother. These are yarns from Lunatic Fringe and all appear in the latest scarf I wove. Hopefully I’ll get to that blog before too long.

These are yarns from Lunatic Fringe and all appear in the latest scarf I wove. Hopefully I’ll get to that blog before too long. This is my latest warp. I wound 13 yards of mixed

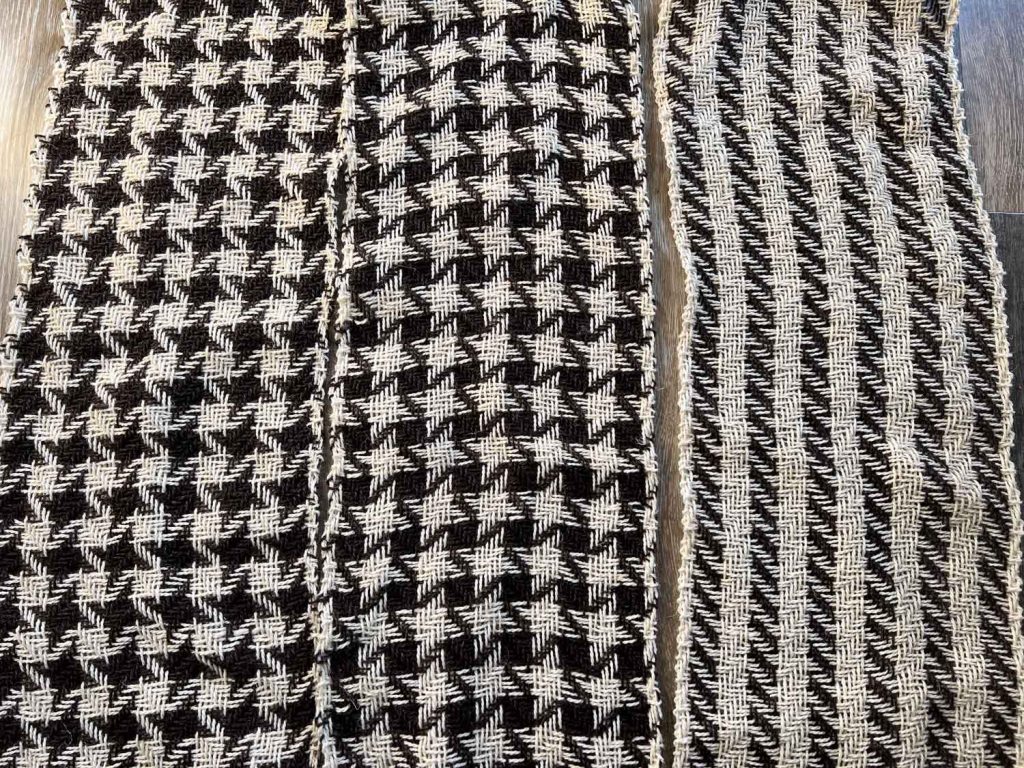

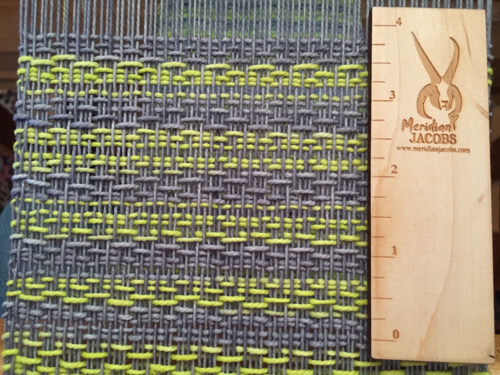

This is my latest warp. I wound 13 yards of mixed  The other thing to notice about this photo is that the last piece woven on it is so much narrower than the others. This was the fourth shawl on the warp. The one before this one is a different weave structure (advancing twill treadling), but the first two are the same structure as the fourth one. The only difference is the weft yarn. The first three shawls were woven with 2015 Timm Ranch yarn on cones. The weft for the fourth shawl is 2016 Timm Ranch yarn that has been dyed. This is a perfect example of the difference that “finishing” yarn can make.

The other thing to notice about this photo is that the last piece woven on it is so much narrower than the others. This was the fourth shawl on the warp. The one before this one is a different weave structure (advancing twill treadling), but the first two are the same structure as the fourth one. The only difference is the weft yarn. The first three shawls were woven with 2015 Timm Ranch yarn on cones. The weft for the fourth shawl is 2016 Timm Ranch yarn that has been dyed. This is a perfect example of the difference that “finishing” yarn can make.  This is one of the previous batch of shawls. It is mostly Jacob yarn but the weft is last year’s Timm Ranch/Jacob blend used from a cone without washing. In this case the width of the warp in the reed was 30″ with a sett of 6 epi. That is very open but when wet finished the shawl is lightweight and has great drape. However, the finished width is only about 20″ (33% draw-in and shrinkage). So I sett the brown warp the same at 6 epi but started with a 39″ wide warp.

This is one of the previous batch of shawls. It is mostly Jacob yarn but the weft is last year’s Timm Ranch/Jacob blend used from a cone without washing. In this case the width of the warp in the reed was 30″ with a sett of 6 epi. That is very open but when wet finished the shawl is lightweight and has great drape. However, the finished width is only about 20″ (33% draw-in and shrinkage). So I sett the brown warp the same at 6 epi but started with a 39″ wide warp. Here are the shawls from the brown warp after wet finishing. That one that was so much narrower on the cloth beam? That is the one that is a little wider here. It is now 27″ wide (30% draw-in and shrinkage). The shawl in the same pattern but woven with the white weft is 26″ wide (33% draw-in and shrinkage). The difference between width in the reed and the finished piece isn’t much, but the photos show the dramatic difference in how the yarn behaves while it is woven.

Here are the shawls from the brown warp after wet finishing. That one that was so much narrower on the cloth beam? That is the one that is a little wider here. It is now 27″ wide (30% draw-in and shrinkage). The shawl in the same pattern but woven with the white weft is 26″ wide (33% draw-in and shrinkage). The difference between width in the reed and the finished piece isn’t much, but the photos show the dramatic difference in how the yarn behaves while it is woven.  Here is a before and after photo. The bottom shawl has been wet finished. The top one is the same weft yarn and same pattern, but has not been washed. Look at the very first photo in this post. You can see how wide open the yarns are. Off the loom they are a little closer, but that looks nothing like it will when finished.

Here is a before and after photo. The bottom shawl has been wet finished. The top one is the same weft yarn and same pattern, but has not been washed. Look at the very first photo in this post. You can see how wide open the yarns are. Off the loom they are a little closer, but that looks nothing like it will when finished.  An example of trying to take product photos with the help of a Border Collie.

An example of trying to take product photos with the help of a Border Collie. Here is one of the final product photos. I noticed a surprise. I started to see a purple cast to one of the warp yarns. At first I thought that I just hadn’t noticed that shade inside while I was weaving. I tried to convince myself that it was still brown.

Here is one of the final product photos. I noticed a surprise. I started to see a purple cast to one of the warp yarns. At first I thought that I just hadn’t noticed that shade inside while I was weaving. I tried to convince myself that it was still brown. Do you see it here?

Do you see it here?  Another photo of one not washed (no purple) and one washed. I lined up the same warp threads in these two pieces.

Another photo of one not washed (no purple) and one washed. I lined up the same warp threads in these two pieces.  Depending on the light setting in the photo (and maybe your monitor) you may see it more clearly in one of these other photos.

Depending on the light setting in the photo (and maybe your monitor) you may see it more clearly in one of these other photos. In person it is clearly visible, although it doesn’t stand out.

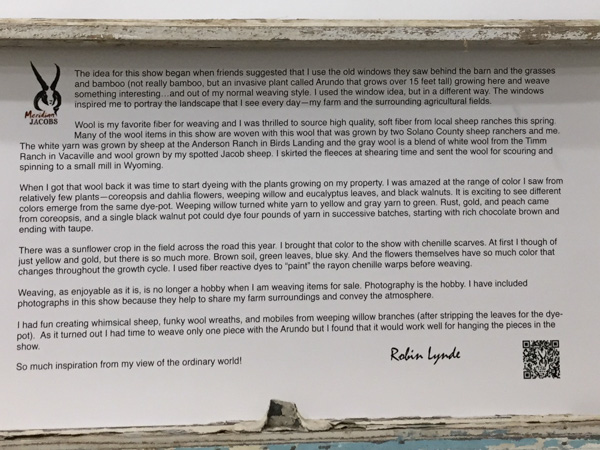

In person it is clearly visible, although it doesn’t stand out. Friends (Lisa and Dona?) said “you should use those old windows that are in back”. They were thinking that I could weave using the windows as weaving frames. They like that sort of thing. I like it too, but I haven’t actually done much of it. My weaving is more functional than decorative–like blankets, shawls, and scarves. I admire things to hang on the wall, but my house has hardly any wall space, and in my world things that hang on the wall just get covered with dust and cobwebs. Still, one point of doing a show is to move outside what is your same-old-stuff.

Friends (Lisa and Dona?) said “you should use those old windows that are in back”. They were thinking that I could weave using the windows as weaving frames. They like that sort of thing. I like it too, but I haven’t actually done much of it. My weaving is more functional than decorative–like blankets, shawls, and scarves. I admire things to hang on the wall, but my house has hardly any wall space, and in my world things that hang on the wall just get covered with dust and cobwebs. Still, one point of doing a show is to move outside what is your same-old-stuff. Wednesday, October 25, 2017. That date was stuck in my head. I had to be Ready. My friends showed up when the gallery opened at 9:30 and we unloaded the truck. All those white cubes were in the gallery from the previous show. The first decision to be made was which cubes to leave for my show. The Artery Display Committee needs to know how many they can use for the other store displays, but the person doing the gallery show gets first choice.

Wednesday, October 25, 2017. That date was stuck in my head. I had to be Ready. My friends showed up when the gallery opened at 9:30 and we unloaded the truck. All those white cubes were in the gallery from the previous show. The first decision to be made was which cubes to leave for my show. The Artery Display Committee needs to know how many they can use for the other store displays, but the person doing the gallery show gets first choice. I wasn’t really sure but narrowed it down to Not Very Many, keeping some of the larger ones.

I wasn’t really sure but narrowed it down to Not Very Many, keeping some of the larger ones. Organizing by color.

Organizing by color.

Half way through the day I needed to get my signs printed for the entry. My friends were going to go get lunch and I asked them to bring back a slice of pizza. They know me well. It was touching that they brought back my favorite beverage, but saved for special stress-invoking occasions like being at the fair all day.

Half way through the day I needed to get my signs printed for the entry. My friends were going to go get lunch and I asked them to bring back a slice of pizza. They know me well. It was touching that they brought back my favorite beverage, but saved for special stress-invoking occasions like being at the fair all day. Lunch break.

Lunch break. As Dona and Mary left at 5-ish I think they wondered if I’d spend the night there.

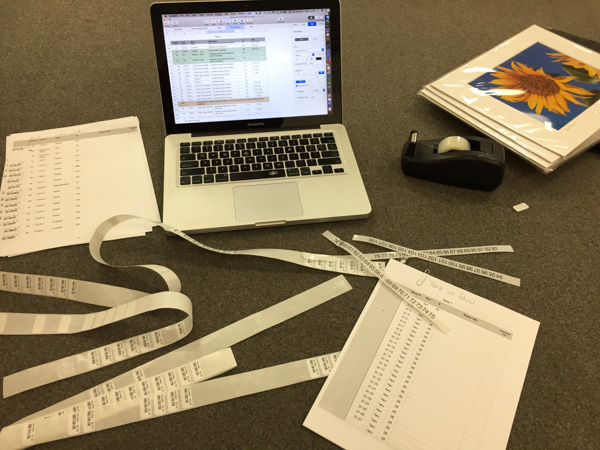

As Dona and Mary left at 5-ish I think they wondered if I’d spend the night there. Keeping track of all the pieces in the show by my inventory number and the show number (not the same), entering pieces into the Artery computer, applying barcodes to the tags, applying bar codes to the sales list at the desk, applying sticky numbers to the wall for each piece. I could have used a chocolate milk. I finished up at about 1:30 on Friday.

Keeping track of all the pieces in the show by my inventory number and the show number (not the same), entering pieces into the Artery computer, applying barcodes to the tags, applying bar codes to the sales list at the desk, applying sticky numbers to the wall for each piece. I could have used a chocolate milk. I finished up at about 1:30 on Friday. This is the display in the front window.

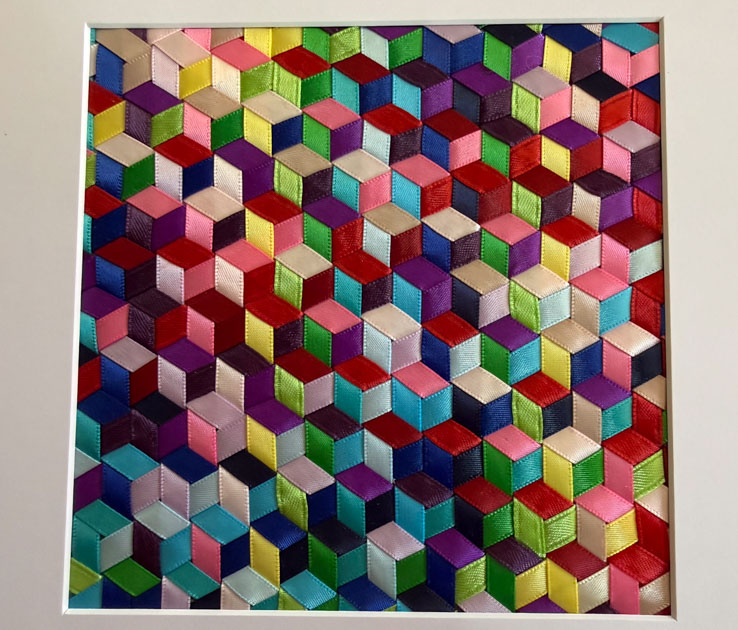

This is the display in the front window.

This was a class about weaving with rayon chenille, a yarn with a reputation of being difficult to work with. I set up 4 warping frames on temporary structures and the fifth person used the one I have mounted on the wall.

This was a class about weaving with rayon chenille, a yarn with a reputation of being difficult to work with. I set up 4 warping frames on temporary structures and the fifth person used the one I have mounted on the wall. After the looms were warped and ready to go I was surprised that it wasn’t all that crowded with five looms. Each person chose a different combination of colors for their scarves:

After the looms were warped and ready to go I was surprised that it wasn’t all that crowded with five looms. Each person chose a different combination of colors for their scarves:

We did take a barn break or two. One lamb was born during class and two more right afterward.

We did take a barn break or two. One lamb was born during class and two more right afterward. Everyone finished weaving in the class time (although fringes will be finished at home) and all were pleased with their scarves.

Everyone finished weaving in the class time (although fringes will be finished at home) and all were pleased with their scarves.