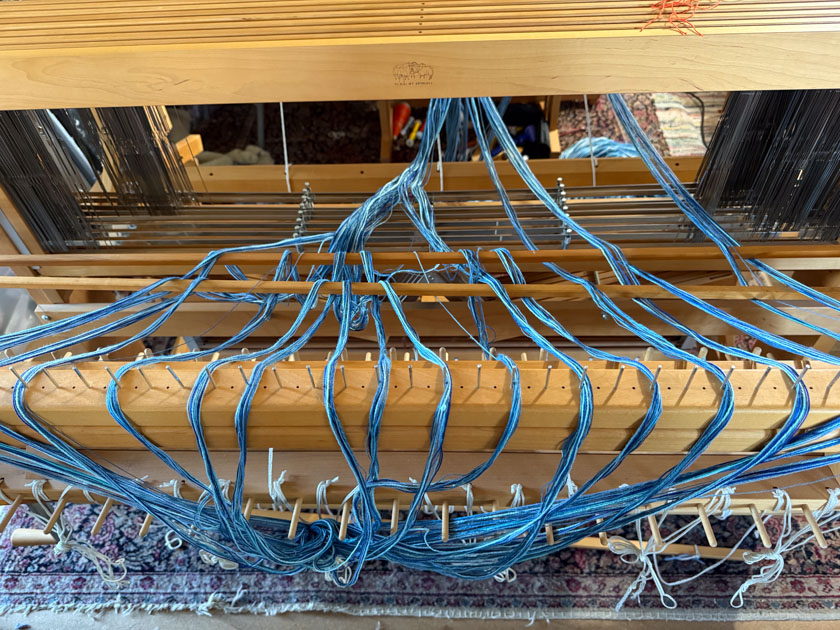

In the 2025 Weaving Recap blog post I included a photo of baby blankets still on the loom and said that warp had been on the loom since October. How about August? That’s what I found when I looked back for photos of warping this loom. Don’t ask me why I decided to wind a warp this way, but it seemed like a good idea at the time.

I used a paddle so each pass was four threads and I made a 26 yard warp.

I have wound 20 or 30 yard warps sectionally using the traditional method for sectional warping or using the AVL warping wheel. But I got this idea of using two warping boards and thought, why not?

I had to wind two bouts to accommodate all the yarn. My goal was to use up odds and ends of cones of yarn so the second warp. That meant the second warp would be different from the first, but I wanted the colors distributed throughout. I spaced the first one out in the raddle.

Then I added the second warp in the empty spaces.

I used two end sticks instead of trying to intersperse the two bouts onto one stick.

This looked good.

This side was a little messier, but it all worked out eventually.

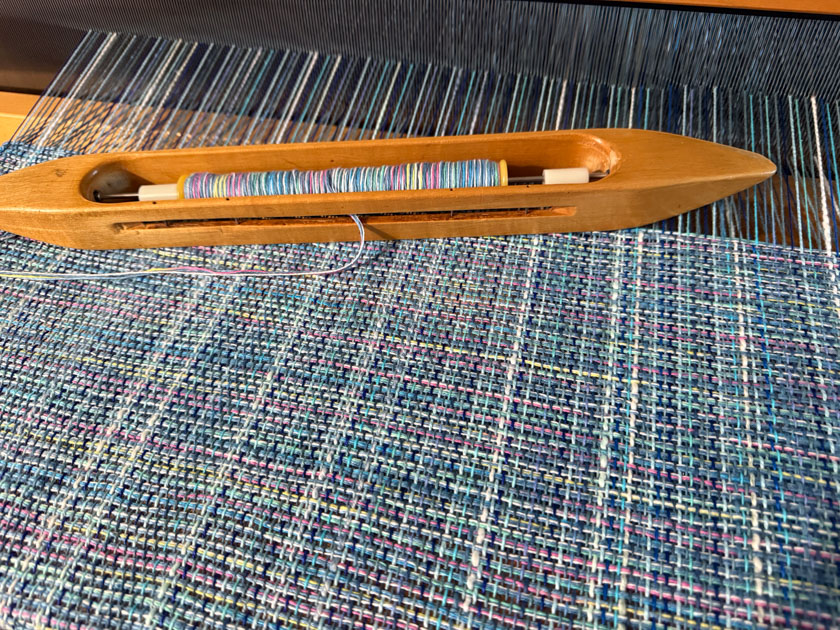

Weaving in progress.

I had an order for blankets so I cut some off the loom early and didn’t get back to that warp until recently.

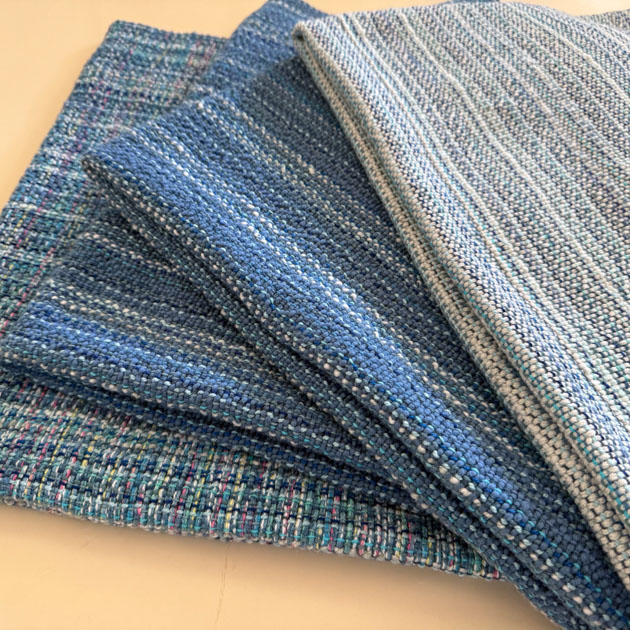

This is the warp I just finished before cutting anything apart. People always ask how long does it take to weave a piece. There are processes other than weaving that go into completing a project. In this case all blankets were machine stitched at each end before cutting them apart. Then some were hemmed. All are washed and then I sew on my label and add the hangtag.

There are multiples of some of these blankets. Those are stacked with two or three.

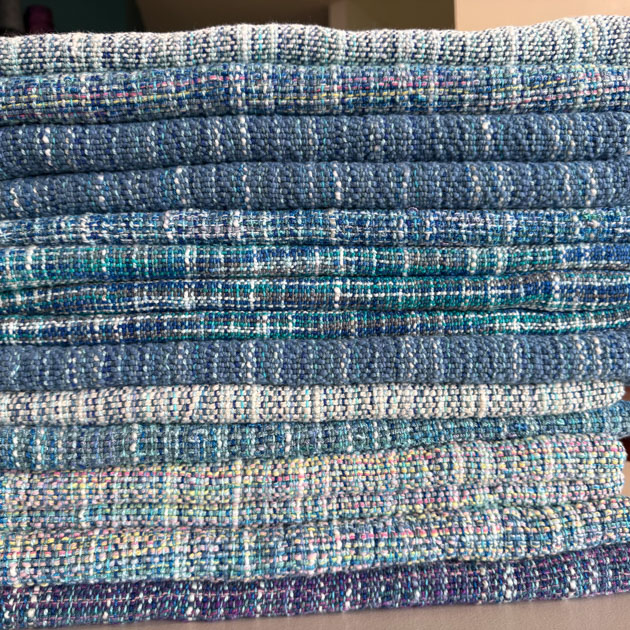

Another view of all the blankets. You can find some of these blankets on my website and here at the farm store. Others are at The Artery and some are on the Artery’s webstore (local pick-up for those right now). Next up will be a white warp so I can have a variety of colors.

Here is the problem. When threading the heddles I inadvertently used 7 heddles from the Shaft #5 when I should have used Shaft #4. This is a 4-shaft structure so #5 didn’t lift at all. It is an easy fix for the second blanket. Just tie Shaft # 5 up to each treadle in which Shaft #4 is engaged.

Here is the problem. When threading the heddles I inadvertently used 7 heddles from the Shaft #5 when I should have used Shaft #4. This is a 4-shaft structure so #5 didn’t lift at all. It is an easy fix for the second blanket. Just tie Shaft # 5 up to each treadle in which Shaft #4 is engaged.

However, the only way to fix Blanket #1 was to needle weave all 7 threads in after it was off the loom. That should be easy (over-under-over;over-under-under), but it took hours because of the nature of the boucle yarn. Thank goodness it was only 7 threads.

However, the only way to fix Blanket #1 was to needle weave all 7 threads in after it was off the loom. That should be easy (over-under-over;over-under-under), but it took hours because of the nature of the boucle yarn. Thank goodness it was only 7 threads.

My old teddy bear (I won’t tell you how old) featured in some of the shots too.

My old teddy bear (I won’t tell you how old) featured in some of the shots too.

And here is the floor behind the loom.

And here is the floor behind the loom.