Lambing started only two weeks ago but is almost over (except for the lambs that will come at the end of April due to acquiring a ram around Thanksgiving). I like to keep my blog posts in chronological order, but I’m giving up on that for now. I may share other lambing photos later, but for now I’ll write this story.

It was only a week ago (Thursday, March 13), that Patchwork Amara lambed. I had put her in the evening before and didn’t see anything when I checked the barn at 2 a.m. When I went back at 6:00 I found a big lamb in good shape and a small lamb that at first I thought was dead. When I picked her up she wasn’t completely flaccid like a dead lamb would be and I could see her take shallow breaths. She was very cold.

I brought the lamb to the house and put her in a dishpan of warm water. As her body warmed she started to move her legs. After I’d warmed her enough I wrapped her in a towel and went back to the barn. I set up a heat lamp and moved Amara and the big lamb to a clean pen. Lisa was helping for a few days and when she came to the barn I gave her lamb holding duty.

I milked colostrum from Amara and tube fed the lamb.

While we were feeding her we realized that Amara was having a third lamb.

Those big brothers were 9.2 and 8.6 pounds. Sparky, as Lisa named her when she showed a spark of life, was only 4 pounds.

I found a size Small coat for Sparky, It was way too big and eventually Lisa cut some off.

Sparky was spunky enough after the tube feeding to nurse on her own. Throughout the day we made sure that she was nursing.

The next morning Amara was tired of having three lambs and was getting a bit aggressive towards Sparky. I didn’t feel comfortable leaving her there and decided that she would be a bottle lamb. That was 6 days ago.

Farm Club members came on Saturday and Sparky was a favorite.

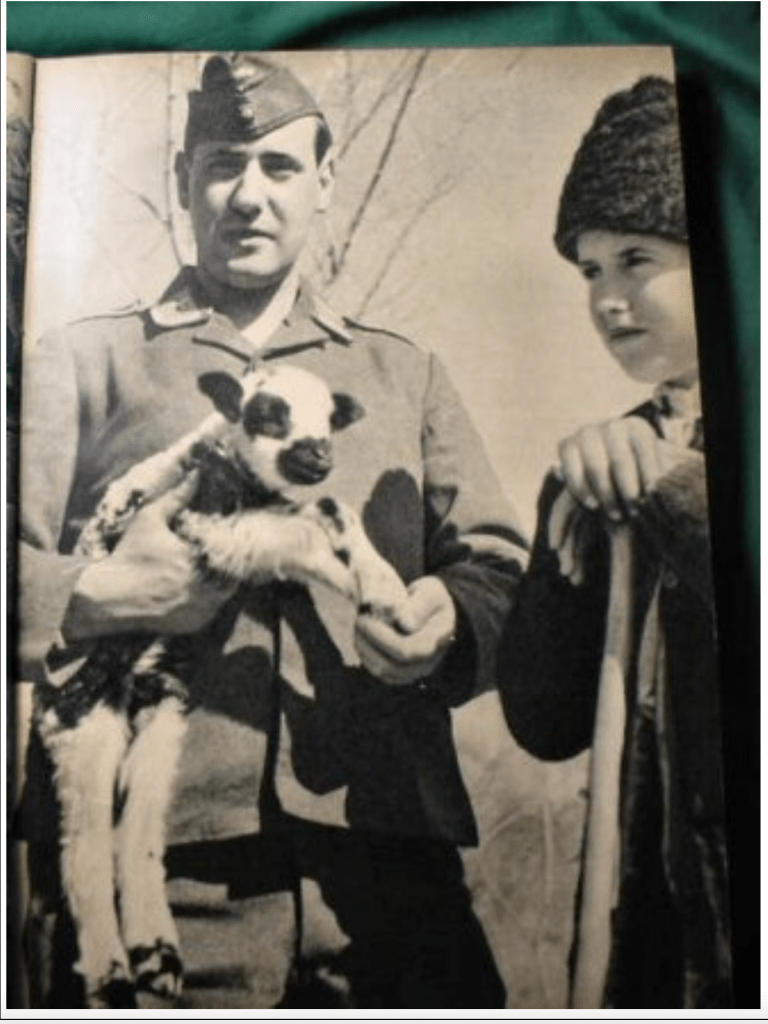

I picked up my grandkids at the airport yesterday and we went to the barn right after we got home. Ten-year-old Kirby.

Eight-year old Kasen. The kids are taking turns bottle feeding, although the next feeding is in a few minutes (11:30 p.m.) and no one has volunteered for that one.

Sparky has had plenty of attention. The kids are taking her out of the barn and letting her run around in the grass. I tried to share a video here don’t know if I can make it work. Let’s try this YouTube link.