I explained the concept behind my Artery show in the last post. Here are some more photos. I’ll start as you walk in the gallery. I have a photo and a story for each ranch whose yarn I used. Columbia sheep at the Imperial Stock Ranch in Oregon.

Columbia sheep at the Imperial Stock Ranch in Oregon.

The story: The Imperial Stock Ranch is located on 32,000 acres in Oregon’s high desert and is owned and operated by the Carver family, who raise sheep and cattle and produce grain and hay.

In the late 1990’s the U.S. processing and manufacturing industry drastically declined (moving overseas) and the ranch, like thousands of others, was unable to sell their wool through traditional commodity channels. If the Carvers were going to continue to raise the Columbia sheep that had grazed the ranch for a century they needed to find a way to market the wool. Jeanne Carver’s response was to create and sell premium wool yarns and the Imperial Yarn Company was born.

The Carvers were thrilled to find out that their home-grown “Erin” yarn was chosen by Ralph Lauren for the 2014 Olympics Opening Ceremony sweaters. I saw this yarn at a trade show and was awed by the rich colors. I knew I had to use this for a Stars and Stripes series of blankets.

The Columbia sheep was developed by the U.S.D.A. in the early 1900’s to create a true-breeding large ewe that would yield more pounds of lamb and wool than the randomly crossbred range sheep. The Columbia is a result of crossing Lincoln rams and Rambouillet ewes and is a very large breed that produces 10-16 pound fleeces that measure 24-31 microns.

Here are some of the blankets that I wove. In another post I’ll explain the process of weaving these blankets. Also look for a later post of shawls using a fine wool yarn from the Imperial Yarn Company. The first blankets that I wove were in blue and white. All of these blankets except the mostly blue ones at the bottom are woven using “color and weave”. The weave structure is the same throughout the blanket but it is the color order of the threads (8 blue/8 white) in the warp and the weft that allow the pattern to show. Where there are solid areas of white or blue in warp and/or weft you don’t see the star pattern.

The first blankets that I wove were in blue and white. All of these blankets except the mostly blue ones at the bottom are woven using “color and weave”. The weave structure is the same throughout the blanket but it is the color order of the threads (8 blue/8 white) in the warp and the weft that allow the pattern to show. Where there are solid areas of white or blue in warp and/or weft you don’t see the star pattern. For a true Stars and Stripes theme I needed to use some red.

For a true Stars and Stripes theme I needed to use some red.

These are the same weave structures as above but with 8 white/8 red/8 blue threads in the pattern area.

These are the same weave structures as above but with 8 white/8 red/8 blue threads in the pattern area. In the first two red, white, and blue blankets I repeated the 8-thread sequence throughout.

In the first two red, white, and blue blankets I repeated the 8-thread sequence throughout. In the next two I designed blocks, sort of plaid like, where the star pattern would show up. Then I decided that there should be something in this collection that was more restful for the eye.

In the next two I designed blocks, sort of plaid like, where the star pattern would show up. Then I decided that there should be something in this collection that was more restful for the eye.  I thought about solid colors but had to throw in a bit of design.

I thought about solid colors but had to throw in a bit of design. In addition to being colorful this yarn is very soft and wonderful to work with for weaving or for knitting. I sell it at my shop and on the website.

In addition to being colorful this yarn is very soft and wonderful to work with for weaving or for knitting. I sell it at my shop and on the website. Next up: Yarn from the Barinaga sheep dairy in Marin County.

Next up: Yarn from the Barinaga sheep dairy in Marin County.

There were about a dozen people there for the tour even at 9 a.m. on a Monday morning. It was interesting to see the workings of the mill but now I have a lot of unanswered questions. We all wore headsets so that we could hear the tour guide over noise of the mill machinery but that meant that there was no opportunity to ask questions while we were walking. And the tour was fast. I would have liked to stop and watch what was going on with each loom. Now that I’m looking at my photos I realize that I have even more questions about what I was seeing. I guess I’ll just have to go back!

There were about a dozen people there for the tour even at 9 a.m. on a Monday morning. It was interesting to see the workings of the mill but now I have a lot of unanswered questions. We all wore headsets so that we could hear the tour guide over noise of the mill machinery but that meant that there was no opportunity to ask questions while we were walking. And the tour was fast. I would have liked to stop and watch what was going on with each loom. Now that I’m looking at my photos I realize that I have even more questions about what I was seeing. I guess I’ll just have to go back! The Mill uses Rambouillet wool from Oregon and surrounding states and Merino wool from New Zealand and Australia. The wool is scoured in Texas and then comes to Oregon for spinning and weaving. The carding and spinning equipment was on the second floor. That room was quite humid. The guide told us that high humidity lessons the quantity of airborne particles so employees don’t have to wear dust masks. Now I wonder if that is the main reason for the humidity or if it makes carding and spinning more efficient (or both). The photo above shows the carding equipment operating behind plexiglass.

The Mill uses Rambouillet wool from Oregon and surrounding states and Merino wool from New Zealand and Australia. The wool is scoured in Texas and then comes to Oregon for spinning and weaving. The carding and spinning equipment was on the second floor. That room was quite humid. The guide told us that high humidity lessons the quantity of airborne particles so employees don’t have to wear dust masks. Now I wonder if that is the main reason for the humidity or if it makes carding and spinning more efficient (or both). The photo above shows the carding equipment operating behind plexiglass.

The sheep are gathered at the back of a trailer that is hauled from ranch to ranch with all the gear. They go up the chute with the encouragement of…

The sheep are gathered at the back of a trailer that is hauled from ranch to ranch with all the gear. They go up the chute with the encouragement of…

Here is a view from the other end of the trailer. That sheep in front hangs out for awhile in that position because the other sheep are more likely to go forward if they see a sheep in front of them. Notice how the sheep walk on a raised alleyway while the freshly shorn fleeces are shoved out of the trailer below them.

Here is a view from the other end of the trailer. That sheep in front hangs out for awhile in that position because the other sheep are more likely to go forward if they see a sheep in front of them. Notice how the sheep walk on a raised alleyway while the freshly shorn fleeces are shoved out of the trailer below them.

Alison spent the morning at the skirting table explaining skirting and helping buyers skirt their fleeces.

Alison spent the morning at the skirting table explaining skirting and helping buyers skirt their fleeces.

Shelby and Gynna were our sheep wranglers, making sure that there was always another sheep for John to shear.

Shelby and Gynna were our sheep wranglers, making sure that there was always another sheep for John to shear.

Lila.

Lila.

And look at this gorgeous one!

And look at this gorgeous one!

Mary let out the bottle babies…

Mary let out the bottle babies…

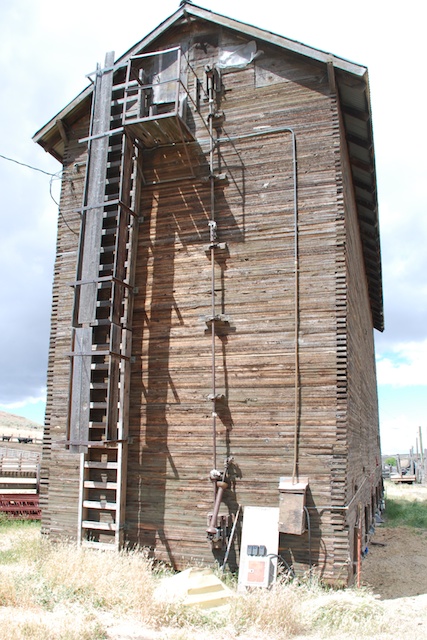

Here is where the fleeces are dried. Mary had several fleeces spread out so that the visitors could handle them and feel the characteristics that we’d been talking about all day.

Here is where the fleeces are dried. Mary had several fleeces spread out so that the visitors could handle them and feel the characteristics that we’d been talking about all day.