Every January I meet up with my long-time friend, Irene, who owns Cotton Clouds, a mail-order business based in Arizona, to go to the Winter Show of The National Needlearts Association. Since I’ve been going it’s been in San Diego (2016 and 2014) or Phoenix (2015 and 2012) or Long Beach (2013 and 2011). This year it was in San Jose, only an hour and a half from here (on a weekend without commute traffic), so Irene flew to Sacramento and spent a few days here before we both drove to the show.

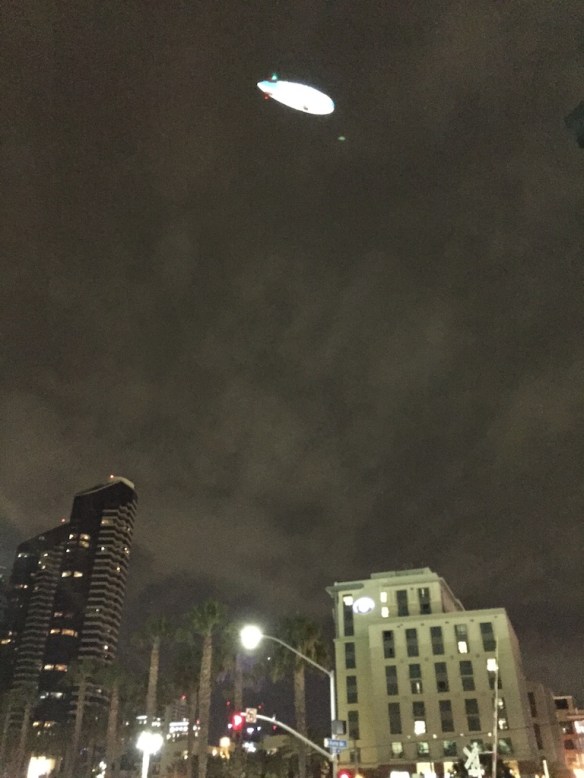

TNNA wasn’t the only thing in town on Saturday.

There was plenty of pink visible.

Other colors too. Why does Irene always look more excited in these photos of us together?

Big fat yarns seem to be the new thing this year.

I managed to find a few sheep.

After spending a few hours at the show we checked into our hotel where we had a room on the 5th floor.

This is the view…

…and this is the art work on the wall.

We went back to the convention hall. We had been seeing groups of young (mostly) men (mostly) wearing black (mostly) who were attending something in the convention center but didn’t quite fit the demographics of the yarn buyers and sellers. Irene spoke to one group and we found out that they were competing in the Super Smash Brothers Tournament, a Nintendo gaming event (if I’m using the right terminology). It’s worth looking at this link for a view into an obsession a little different than the fiber one (maybe takes up less space?) A quote from the article: “For video games you don’t need depth perception at all,” he explains, sounding almost Baudrillardian, “there’s no depth: it’s just right there.” Put in perspective, that quote is from a gamer who is blind in on eye. We may bring out fiber swatches and knitting needles. They bring their own controllers.

Back to the Fiber Hall.

I love how this sign was made.

Very clever.

I like the look of this fabric…

…woven on this loom which I have in the shop and eventually on the website.

We talked with a lot of vendors. This is Francis Chester-Cestari who has sheep and a fiber mill in Virginia and promotes American grown fiber. Irene is looking at some of his U.S. grown cotton. Notice the book on his table. That’s his memoir.

I didn’t come away from this show with all the new products that I usually do, although I do have some lotion bars with sheep on them (see photo in one of the collections above). There weren’t as many vendors and I really don’t need more yarn. What I need is a better way to market what I already have before adding more. So my investment this year is a new modern website! You’ll be hearing more about that in a month or so.

This photo doesn’t do justice to the pile of stuff. Most of them are still out in the aisle. A couple of people stopped by and were amazed that I actually fit it all in. What you don’t notice in the photo because of the black drapes are the 16 gridwall panels that create the booth. Those get heavier every year.

This photo doesn’t do justice to the pile of stuff. Most of them are still out in the aisle. A couple of people stopped by and were amazed that I actually fit it all in. What you don’t notice in the photo because of the black drapes are the 16 gridwall panels that create the booth. Those get heavier every year. I got to Modesto about 4:30 p.m., worked until 8:40 on Thursday and then from about 9:30 to 1:30 today. The show opened at 2. Here is a tour of my booth:

I got to Modesto about 4:30 p.m., worked until 8:40 on Thursday and then from about 9:30 to 1:30 today. The show opened at 2. Here is a tour of my booth: Rusty’s Yarn faces the aisle.

Rusty’s Yarn faces the aisle. On the 3-grid tower in the middle I have the Meow and Woof yarns…

On the 3-grid tower in the middle I have the Meow and Woof yarns… …Sprout yarns…

…Sprout yarns… …and Mountain Meadows, all fingering weight yarns with sample scarves.

…and Mountain Meadows, all fingering weight yarns with sample scarves. Around the inside of the booth is the Timm Ranch yarn with blankets I wove and Mary’s beautiful shawl. There are Jacob sheepskins too–only a few left.

Around the inside of the booth is the Timm Ranch yarn with blankets I wove and Mary’s beautiful shawl. There are Jacob sheepskins too–only a few left. Moving to the left there is the Jacob yarn and Imperial Yarn Company’s “Anna”, a wool/cotton yarn that weaves up quickly (at 5 epi).

Moving to the left there is the Jacob yarn and Imperial Yarn Company’s “Anna”, a wool/cotton yarn that weaves up quickly (at 5 epi). Going around the back wall I have rigid heddle looms from Ashford and Schacht and the Ashford “Katie”, which is a wonderful very portable 8-shaft table loom.

Going around the back wall I have rigid heddle looms from Ashford and Schacht and the Ashford “Katie”, which is a wonderful very portable 8-shaft table loom. Purl & Loop Stash Blaster looms and Swatch Maker looms are brand new. Next to them are the Zoom looms with the critter kits that use squares made on the them.

Purl & Loop Stash Blaster looms and Swatch Maker looms are brand new. Next to them are the Zoom looms with the critter kits that use squares made on the them. Coming around the corner I have photo notecards, buttons, and Meridian Jacobs bags and aprons.

Coming around the corner I have photo notecards, buttons, and Meridian Jacobs bags and aprons. I have added to the horn buttons. My son helped finish off another batch.

I have added to the horn buttons. My son helped finish off another batch. Last there is Cormo Sport yarn dyed by Sincere Sheep. You can see one of the samples that I wove. It is incredibly soft and spongy (not a good wool term, but is it better than squishy? I probably need a different adjective, but it’s late.) I brought Power Scour, etc with me but barely found room for a few bottles.

Last there is Cormo Sport yarn dyed by Sincere Sheep. You can see one of the samples that I wove. It is incredibly soft and spongy (not a good wool term, but is it better than squishy? I probably need a different adjective, but it’s late.) I brought Power Scour, etc with me but barely found room for a few bottles. When I asked how many alpacas there are, Mary said between 150 and 200. They roam the hills on the ranch, accompanied by guardian dogs.

When I asked how many alpacas there are, Mary said between 150 and 200. They roam the hills on the ranch, accompanied by guardian dogs. This is one of the many ranch dogs that include guardian and herding dogs. We were told that this one is only 8 months old.

This is one of the many ranch dogs that include guardian and herding dogs. We were told that this one is only 8 months old. Our meeting was in the greenhouse located near the field where the bucks live.

Our meeting was in the greenhouse located near the field where the bucks live. This guy seemed pretty friendly.

This guy seemed pretty friendly. Before we started the meeting we admired each others fiber products. This is one of the Twirl yarns produced by Mary.

Before we started the meeting we admired each others fiber products. This is one of the Twirl yarns produced by Mary. This is what I brought to share–sheepskins, buttons, yarn, and shawls from my Jacob sheep. The new

This is what I brought to share–sheepskins, buttons, yarn, and shawls from my Jacob sheep. The new  This is a felted hat made by

This is a felted hat made by  Here is

Here is  …and this is a piece she felted from the wool of Vicki, one of my Jacob sheep.

…and this is a piece she felted from the wool of Vicki, one of my Jacob sheep. We were able to see the recently produced Wool and Fine Fiber Book. Each producer has a spread in which samples of their fiber is attached. These books will be circulated to designers and manufacturers who want to find out what kinds of fiber are available locally, how to contact the producers, and to learn how these fibers might be used in end products. This was an amazing undertaking by Fibershed.

We were able to see the recently produced Wool and Fine Fiber Book. Each producer has a spread in which samples of their fiber is attached. These books will be circulated to designers and manufacturers who want to find out what kinds of fiber are available locally, how to contact the producers, and to learn how these fibers might be used in end products. This was an amazing undertaking by Fibershed. While hearing about all this we were also doing what Fibershed producers do best, eating and baby animal snuggling. This is a two-day old kid who needs some TLC.

While hearing about all this we were also doing what Fibershed producers do best, eating and baby animal snuggling. This is a two-day old kid who needs some TLC. One of the dogs was feeling left out.

One of the dogs was feeling left out. Even Rebecca found some goat snuggling time.

Even Rebecca found some goat snuggling time. I hadn’t had a chance to do anything with it until recently. The first step was to gather some information.

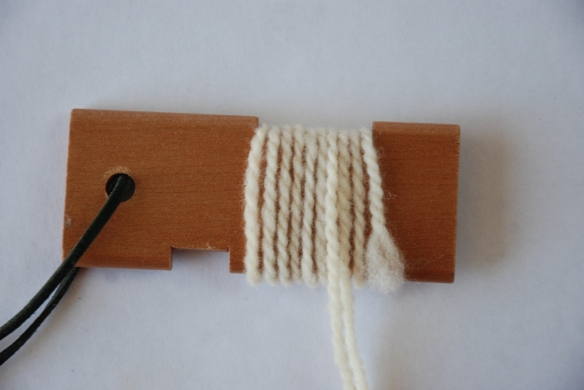

I hadn’t had a chance to do anything with it until recently. The first step was to gather some information. The McMorran yarn balance is one tool to do that. You trim the ends off a strand of yarn until the arm balances.

The McMorran yarn balance is one tool to do that. You trim the ends off a strand of yarn until the arm balances. Then you measure that length of yarn and multiply by 100 to get ypp (yards/pound). I repeated that a few times to get an average–1500 ypp.

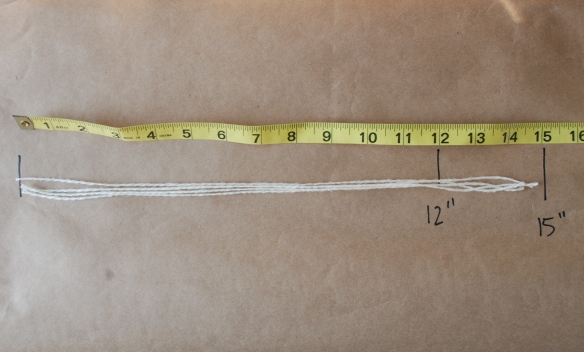

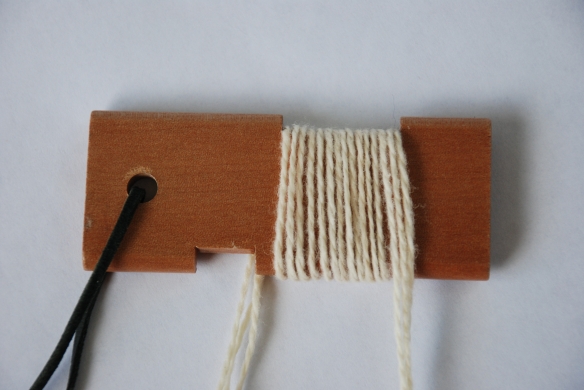

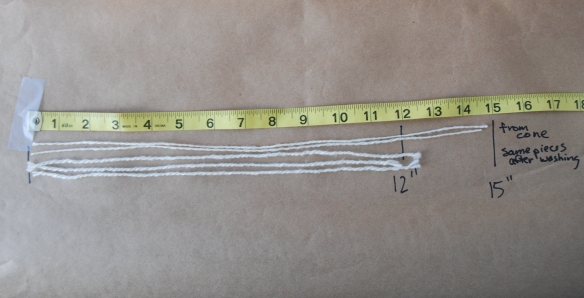

Then you measure that length of yarn and multiply by 100 to get ypp (yards/pound). I repeated that a few times to get an average–1500 ypp. Another measurement is wpi (wraps/inch). This yarn measure 15 wpi. However, from past experience I know that this isn’t quite accurate. Most yarn is scoured (washed) and skeined before it is sold in yarn stores. That can have a dramatic effect on the yarn. The yarn that I got from the mill on cones has not been scoured yet, so it is not really “finished”.

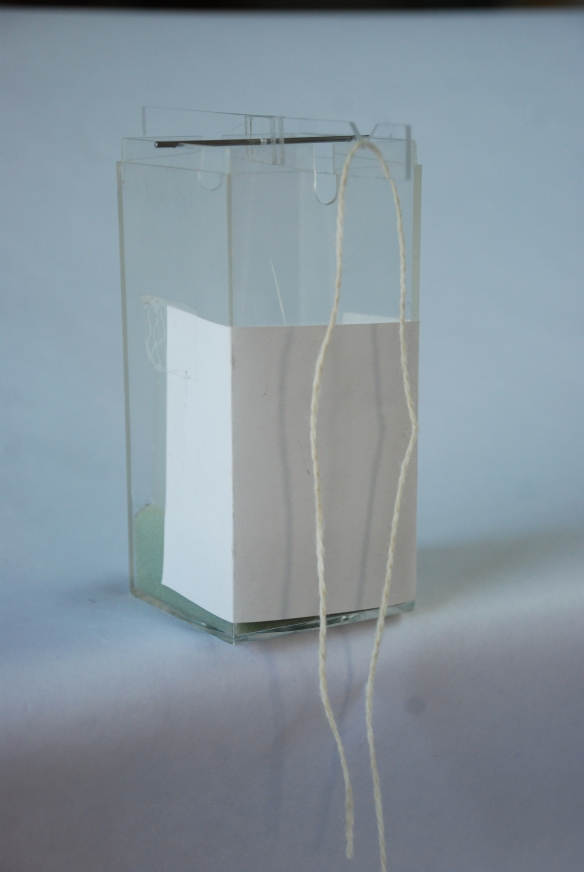

Another measurement is wpi (wraps/inch). This yarn measure 15 wpi. However, from past experience I know that this isn’t quite accurate. Most yarn is scoured (washed) and skeined before it is sold in yarn stores. That can have a dramatic effect on the yarn. The yarn that I got from the mill on cones has not been scoured yet, so it is not really “finished”. Look at the difference a soak in warm water makes. Now this yarn measure 1200 ypp (which is what the specs from the mill were)…

Look at the difference a soak in warm water makes. Now this yarn measure 1200 ypp (which is what the specs from the mill were)… and it is 10 wpi. Based on those measurements I wove some samples.

and it is 10 wpi. Based on those measurements I wove some samples. These samples look pretty open on the loom…

These samples look pretty open on the loom… …and I had to be careful to not beat the weft yarn down too much.

…and I had to be careful to not beat the weft yarn down too much. This is how the samples look off the loom. The 8 epi samples are in the top row.

This is how the samples look off the loom. The 8 epi samples are in the top row. And here is how they look after a quick wash. Dramatic difference from the loom to the finished fabric.

And here is how they look after a quick wash. Dramatic difference from the loom to the finished fabric. Here is how I had them displayed in the shop at the recent Shearing Day. The skein on the left has been washed. But these yarns aren’t just for weaving. My friend, Mary, bought some, washed it, and then used it for a Mystery Knit Along. Here is the shawl she knit.

Here is how I had them displayed in the shop at the recent Shearing Day. The skein on the left has been washed. But these yarns aren’t just for weaving. My friend, Mary, bought some, washed it, and then used it for a Mystery Knit Along. Here is the shawl she knit. This was knit over a few weeks with a new direction given out each week.

This was knit over a few weeks with a new direction given out each week. It is gorgeous in person and has a wonderful hand. I can’t wait to get some of this yarn on the loom and get to work with it.

It is gorgeous in person and has a wonderful hand. I can’t wait to get some of this yarn on the loom and get to work with it. This is the beautiful Horton Grand Hotel…

This is the beautiful Horton Grand Hotel… …and this is Sunshine, a paper-mache horse who stands in the lobby. He came from the saddle shop that was on the ground floor of the neighboring less formal hotel. The hotels were built in the mid 1800’s but the saddle shop originated in 1912. Wickipedia says: “Both hotels were scheduled for demolition in the 1970s when the City of San Diego purchased them to build the Horton Plaza shopping center on the site. The hotels were dismantled brick by brick, with each brick numbered, catalogued, and stored. In 1986 the hotels were rebuilt into an entirely new hotel at the present location at Fourth Street and Island Avenue.”

…and this is Sunshine, a paper-mache horse who stands in the lobby. He came from the saddle shop that was on the ground floor of the neighboring less formal hotel. The hotels were built in the mid 1800’s but the saddle shop originated in 1912. Wickipedia says: “Both hotels were scheduled for demolition in the 1970s when the City of San Diego purchased them to build the Horton Plaza shopping center on the site. The hotels were dismantled brick by brick, with each brick numbered, catalogued, and stored. In 1986 the hotels were rebuilt into an entirely new hotel at the present location at Fourth Street and Island Avenue.” Our room was lovely.

Our room was lovely. What fun to decorate a hotel like this. The furniture was all old so I assume it was found at estate sales and flea markets. We even had a fireplace (gas so no wool hauling).

What fun to decorate a hotel like this. The furniture was all old so I assume it was found at estate sales and flea markets. We even had a fireplace (gas so no wool hauling). We spent a lot of our time at the San Diego Convention Center.

We spent a lot of our time at the San Diego Convention Center. Here is a message to be read on the way there. This quote in context of time and author if quite serious. In my world the last sentence has particular meaning and is serious enough in my life, if not with as profound a meaning.

Here is a message to be read on the way there. This quote in context of time and author if quite serious. In my world the last sentence has particular meaning and is serious enough in my life, if not with as profound a meaning.  Fun view while going up the escalator in the Convention Center.

Fun view while going up the escalator in the Convention Center. Leaving the hotel at night. This is the Gas Lamp District, kind of like Old Sac is for Sacramento.

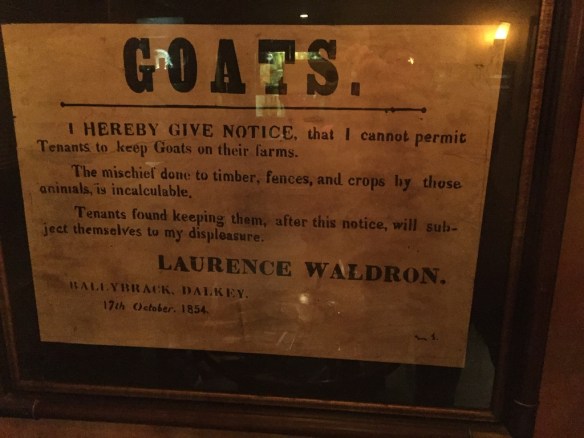

Leaving the hotel at night. This is the Gas Lamp District, kind of like Old Sac is for Sacramento. We ate one night at The Field, an Irish pub, while listening to Irish music and dancers. This sign caught my notice.

We ate one night at The Field, an Irish pub, while listening to Irish music and dancers. This sign caught my notice. But first I found some new equipment. These are prototypes of cool little sample looms designed by author and teacher, Liz Gipson. The unique thing about these looms is that they will be produced in 8, 10, and 12 epi versions, enabling quick sampling of yarns at those setts (and at 4, 5, and 6 epi). There are a few other gadgets I am purchasing here as well.

But first I found some new equipment. These are prototypes of cool little sample looms designed by author and teacher, Liz Gipson. The unique thing about these looms is that they will be produced in 8, 10, and 12 epi versions, enabling quick sampling of yarns at those setts (and at 4, 5, and 6 epi). There are a few other gadgets I am purchasing here as well.  This is the Meow and Woof collection from Ancient Arts Yarns. Each yarn has a photo of the cat or dog that inspired the color. I strayed from my “buy American” plan because I was so enamored with these. They were spun in Italy and are sold by a Canadian company and a percentage of sales goes to dog and cat rescue groups. I have wove a scarf out of the calico cat yarn–that is another post.

This is the Meow and Woof collection from Ancient Arts Yarns. Each yarn has a photo of the cat or dog that inspired the color. I strayed from my “buy American” plan because I was so enamored with these. They were spun in Italy and are sold by a Canadian company and a percentage of sales goes to dog and cat rescue groups. I have wove a scarf out of the calico cat yarn–that is another post. I already

I already  The Fiber Seed will be a new yarn for me. They have some wonderful gradient yarns put together in kits. I’ll get those as well as some of the solids and variegated yarns.

The Fiber Seed will be a new yarn for me. They have some wonderful gradient yarns put together in kits. I’ll get those as well as some of the solids and variegated yarns.

This is 5 batches of yarn out of the same dye pot. The first four skeins on the top are from the first batch. The next four are from the second and I crammed the tablecloth in that pot too. The rest of that row is from the third batch using the same dye. It looked like there was still plenty of dye in the pot so I did two more batches that are on the bottom row. They are lighter but still colored.

This is 5 batches of yarn out of the same dye pot. The first four skeins on the top are from the first batch. The next four are from the second and I crammed the tablecloth in that pot too. The rest of that row is from the third batch using the same dye. It looked like there was still plenty of dye in the pot so I did two more batches that are on the bottom row. They are lighter but still colored.  Here is another view. It is interesting (at least to me) that the fifth batch appears to have slightly more color than the fourth. It is a different yarn. The first four batches included

Here is another view. It is interesting (at least to me) that the fifth batch appears to have slightly more color than the fourth. It is a different yarn. The first four batches included

I was photographing the skeins outside and out of the corner of my eye I kept seeing this other brilliant color.

I was photographing the skeins outside and out of the corner of my eye I kept seeing this other brilliant color.

Another great way to waste time when using technology! But it’s better for you than drugs. The iPad app is called Kaleio and the iPhone one is Teleidoscope.

Another great way to waste time when using technology! But it’s better for you than drugs. The iPad app is called Kaleio and the iPhone one is Teleidoscope.

In September I got the yarn back from the mill and used it for pieces in my show at

In September I got the yarn back from the mill and used it for pieces in my show at

In the first two red, white, and blue blankets I repeated the 8-thread sequence throughout.

In the first two red, white, and blue blankets I repeated the 8-thread sequence throughout. In the next two I designed blocks, sort of plaid like, where the star pattern would show up. Then I decided that there should be something in this collection that was more restful for the eye.

In the next two I designed blocks, sort of plaid like, where the star pattern would show up. Then I decided that there should be something in this collection that was more restful for the eye.