I was looking for a photo earlier and got distracted by others that were of memorable events. Then I realized it had been a long time since I searched for a number to see which photos showed up. I chose 1225 and searched my Lightroom catalog for that number. I turned up a group that is not that exciting, but there are some stories attached.

In May 2017 a group of friends and I went to the Maryland Sheep and Wool Festival. We made our trip long enough for some sight seeing. One of our stops was Assateague Island National Seashore where we saw ponies. Here is the story about that.

This is from setting up a show at The Artery in November, 2017. I called the show Loom With a View. In looking back through the photos I have two conclusions. One is that it it looked pretty good. The second is that my style hasn’t changed much. Is that a good thing–in that I weave functional pieces with a recognizable style? Or not so good in that I haven’t evolved? Here is a link to the post about setting up that show.

Maybe this is cheating to keep within the theme of this post (photo # 1225), but here is a photo of how the room looked.

The next #1225 photo is from March 2021. Ahhh, the pandemic years of wearing masks everywhere. I can’t find a blog post from this shearing at the Timm Ranch but here are two from shearing in 2019 and shearing in 2022.

This is not Photo #1225 but Warp #1225. That’s the 1225th warp since I started keeping track. I guess if I run out of ideas for blog posts I could go back in those archives as well. This warp was a sampler that I ended up using to develop the class I just taught last month. Blog post is here. Class description is here.

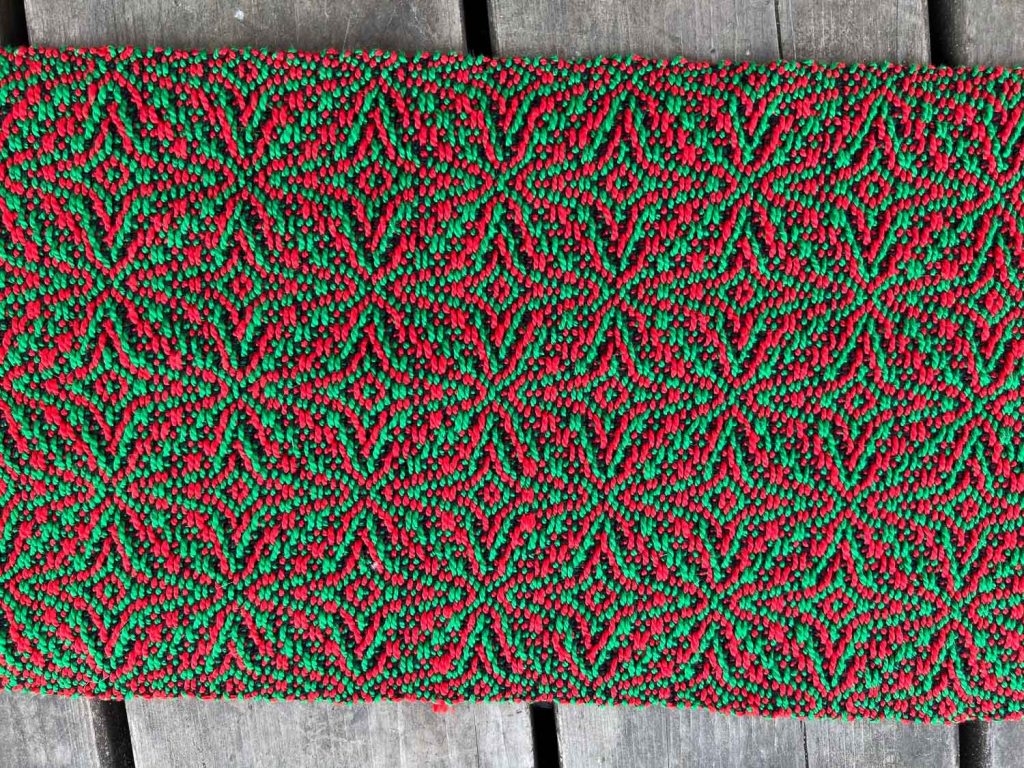

This piece is from that same warp and seems to be an appropriate end for Christmas Eve.

Chenille scarf using clasped weft.

Chenille scarf using clasped weft. Local yarns dyed with coreopsis and dahlia flowers.

Local yarns dyed with coreopsis and dahlia flowers. More local yarns dyed with mushroom and black walnut.

More local yarns dyed with mushroom and black walnut. This is the stack of ponchos that I finished in early November just before the Fibershed Wool Symposium.

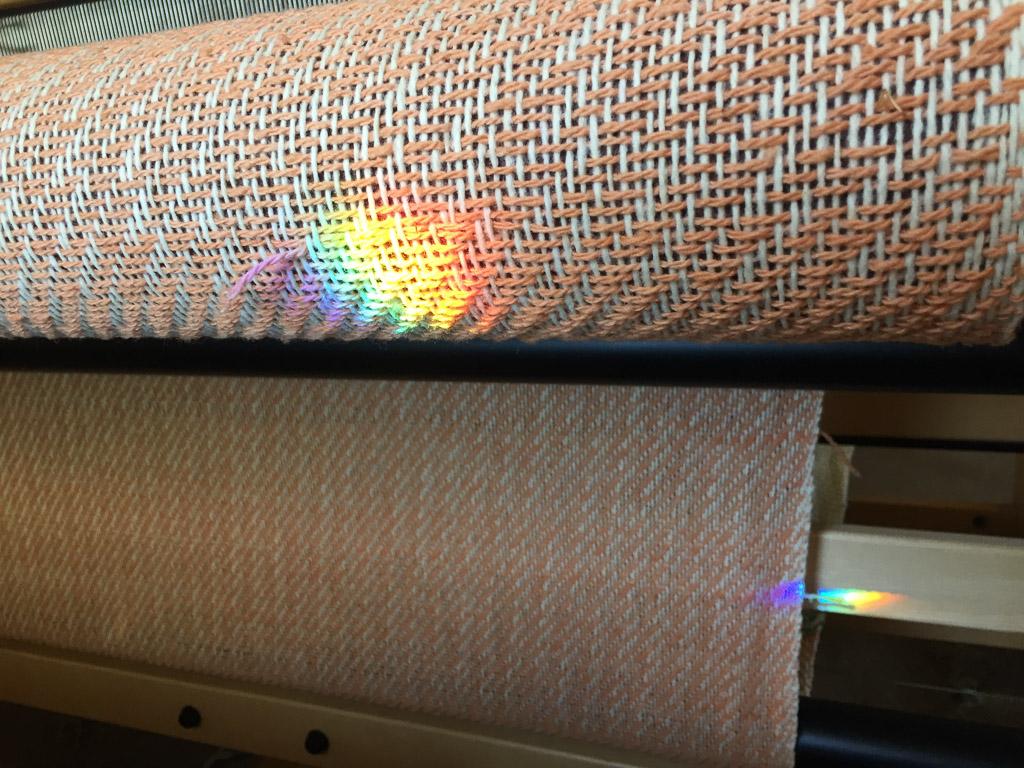

This is the stack of ponchos that I finished in early November just before the Fibershed Wool Symposium. This is how the loom looks from where I sit.

This is how the loom looks from where I sit. The rainbow colors are a result of a prism that hangs in the window behind me. After my mom died a friend gave me the prism and said that it was to remind me of my mom. And it does, as it reminds me of the friend, Sylvia.

The rainbow colors are a result of a prism that hangs in the window behind me. After my mom died a friend gave me the prism and said that it was to remind me of my mom. And it does, as it reminds me of the friend, Sylvia. Coreopsis dyed yarn.

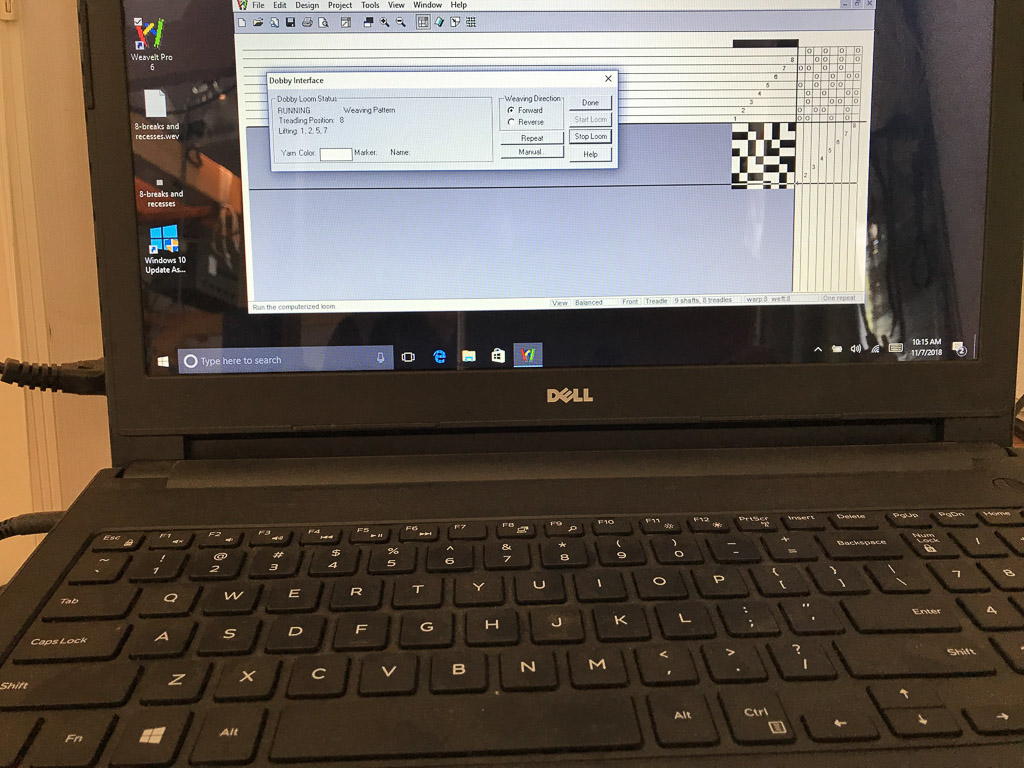

Coreopsis dyed yarn. The computer that holds the “brains” of the loom. This loom does not weave without me doing everything (for those people who think that having a computer hooked up means I’m not really weaving). It only keeps track of the pattern that I have put in.

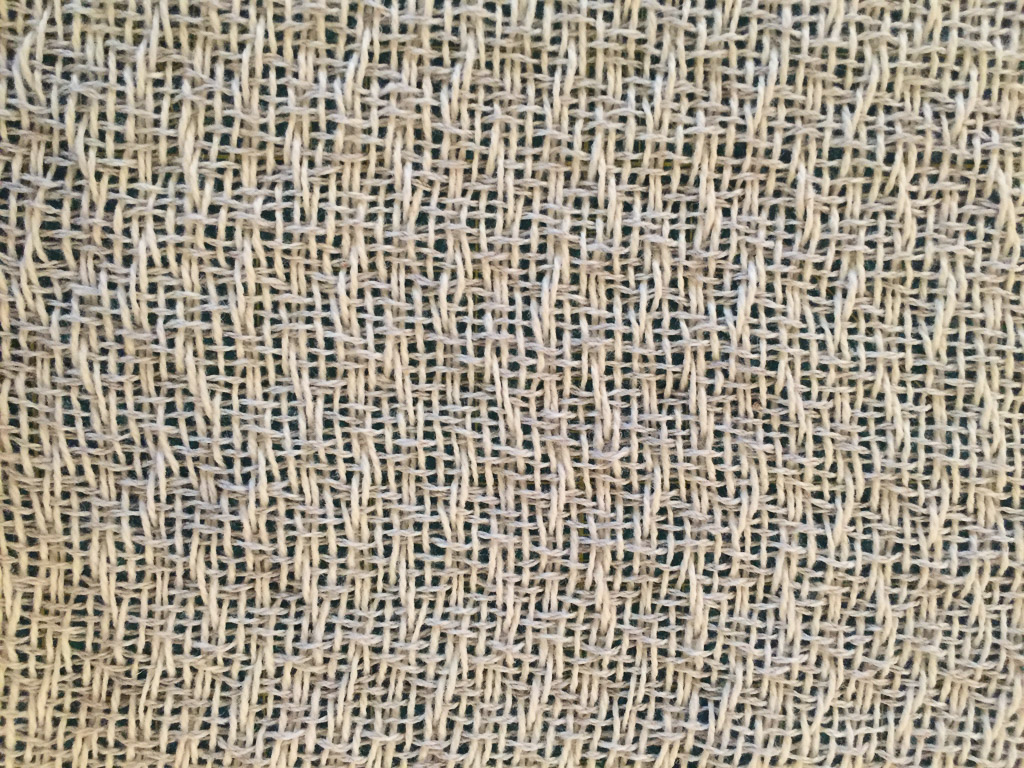

The computer that holds the “brains” of the loom. This loom does not weave without me doing everything (for those people who think that having a computer hooked up means I’m not really weaving). It only keeps track of the pattern that I have put in. This is what that pattern looks like. It will be completely different after fulling.

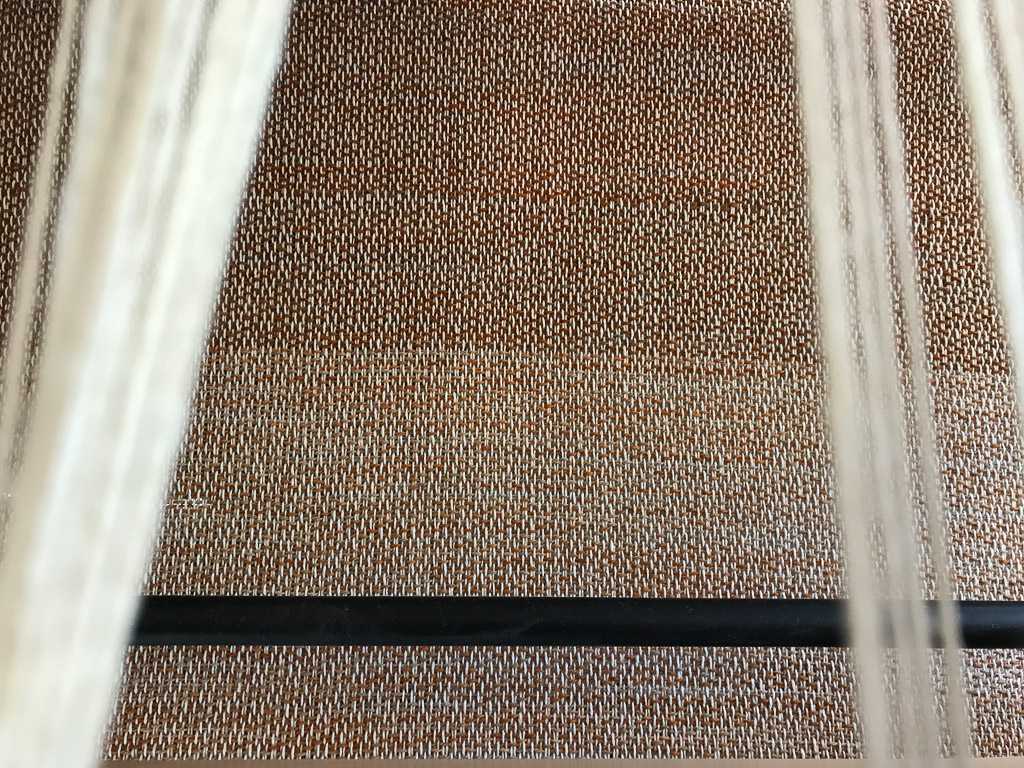

This is what that pattern looks like. It will be completely different after fulling. A look down through the warp threads to the cloth below.

A look down through the warp threads to the cloth below. OOPS! I think I have this in an earlier photo and I haven’t told the story yet of what I did about it. That will still come.

OOPS! I think I have this in an earlier photo and I haven’t told the story yet of what I did about it. That will still come. Some of the finished ponchos.

Some of the finished ponchos.

Talk about a versatile garment. I have grown to love the poncho. It’s really just a blanket with a hole in the middle for your head. Whether you’re at the computer late at night (gee, does that ever happen?), in the car, or trying to stay warm while reading in bed it’s an easy garment to throw on. And it also makes you look young and pretty! Just look at those photos! (Disclaimer–that’s really not me.)

Talk about a versatile garment. I have grown to love the poncho. It’s really just a blanket with a hole in the middle for your head. Whether you’re at the computer late at night (gee, does that ever happen?), in the car, or trying to stay warm while reading in bed it’s an easy garment to throw on. And it also makes you look young and pretty! Just look at those photos! (Disclaimer–that’s really not me.) This is my latest warp. I wound 13 yards of mixed

This is my latest warp. I wound 13 yards of mixed  The other thing to notice about this photo is that the last piece woven on it is so much narrower than the others. This was the fourth shawl on the warp. The one before this one is a different weave structure (advancing twill treadling), but the first two are the same structure as the fourth one. The only difference is the weft yarn. The first three shawls were woven with 2015 Timm Ranch yarn on cones. The weft for the fourth shawl is 2016 Timm Ranch yarn that has been dyed. This is a perfect example of the difference that “finishing” yarn can make.

The other thing to notice about this photo is that the last piece woven on it is so much narrower than the others. This was the fourth shawl on the warp. The one before this one is a different weave structure (advancing twill treadling), but the first two are the same structure as the fourth one. The only difference is the weft yarn. The first three shawls were woven with 2015 Timm Ranch yarn on cones. The weft for the fourth shawl is 2016 Timm Ranch yarn that has been dyed. This is a perfect example of the difference that “finishing” yarn can make.  This is one of the previous batch of shawls. It is mostly Jacob yarn but the weft is last year’s Timm Ranch/Jacob blend used from a cone without washing. In this case the width of the warp in the reed was 30″ with a sett of 6 epi. That is very open but when wet finished the shawl is lightweight and has great drape. However, the finished width is only about 20″ (33% draw-in and shrinkage). So I sett the brown warp the same at 6 epi but started with a 39″ wide warp.

This is one of the previous batch of shawls. It is mostly Jacob yarn but the weft is last year’s Timm Ranch/Jacob blend used from a cone without washing. In this case the width of the warp in the reed was 30″ with a sett of 6 epi. That is very open but when wet finished the shawl is lightweight and has great drape. However, the finished width is only about 20″ (33% draw-in and shrinkage). So I sett the brown warp the same at 6 epi but started with a 39″ wide warp. Here are the shawls from the brown warp after wet finishing. That one that was so much narrower on the cloth beam? That is the one that is a little wider here. It is now 27″ wide (30% draw-in and shrinkage). The shawl in the same pattern but woven with the white weft is 26″ wide (33% draw-in and shrinkage). The difference between width in the reed and the finished piece isn’t much, but the photos show the dramatic difference in how the yarn behaves while it is woven.

Here are the shawls from the brown warp after wet finishing. That one that was so much narrower on the cloth beam? That is the one that is a little wider here. It is now 27″ wide (30% draw-in and shrinkage). The shawl in the same pattern but woven with the white weft is 26″ wide (33% draw-in and shrinkage). The difference between width in the reed and the finished piece isn’t much, but the photos show the dramatic difference in how the yarn behaves while it is woven.  Here is a before and after photo. The bottom shawl has been wet finished. The top one is the same weft yarn and same pattern, but has not been washed. Look at the very first photo in this post. You can see how wide open the yarns are. Off the loom they are a little closer, but that looks nothing like it will when finished.

Here is a before and after photo. The bottom shawl has been wet finished. The top one is the same weft yarn and same pattern, but has not been washed. Look at the very first photo in this post. You can see how wide open the yarns are. Off the loom they are a little closer, but that looks nothing like it will when finished.  An example of trying to take product photos with the help of a Border Collie.

An example of trying to take product photos with the help of a Border Collie. Here is one of the final product photos. I noticed a surprise. I started to see a purple cast to one of the warp yarns. At first I thought that I just hadn’t noticed that shade inside while I was weaving. I tried to convince myself that it was still brown.

Here is one of the final product photos. I noticed a surprise. I started to see a purple cast to one of the warp yarns. At first I thought that I just hadn’t noticed that shade inside while I was weaving. I tried to convince myself that it was still brown. Do you see it here?

Do you see it here?  Another photo of one not washed (no purple) and one washed. I lined up the same warp threads in these two pieces.

Another photo of one not washed (no purple) and one washed. I lined up the same warp threads in these two pieces.  Depending on the light setting in the photo (and maybe your monitor) you may see it more clearly in one of these other photos.

Depending on the light setting in the photo (and maybe your monitor) you may see it more clearly in one of these other photos. In person it is clearly visible, although it doesn’t stand out.

In person it is clearly visible, although it doesn’t stand out.

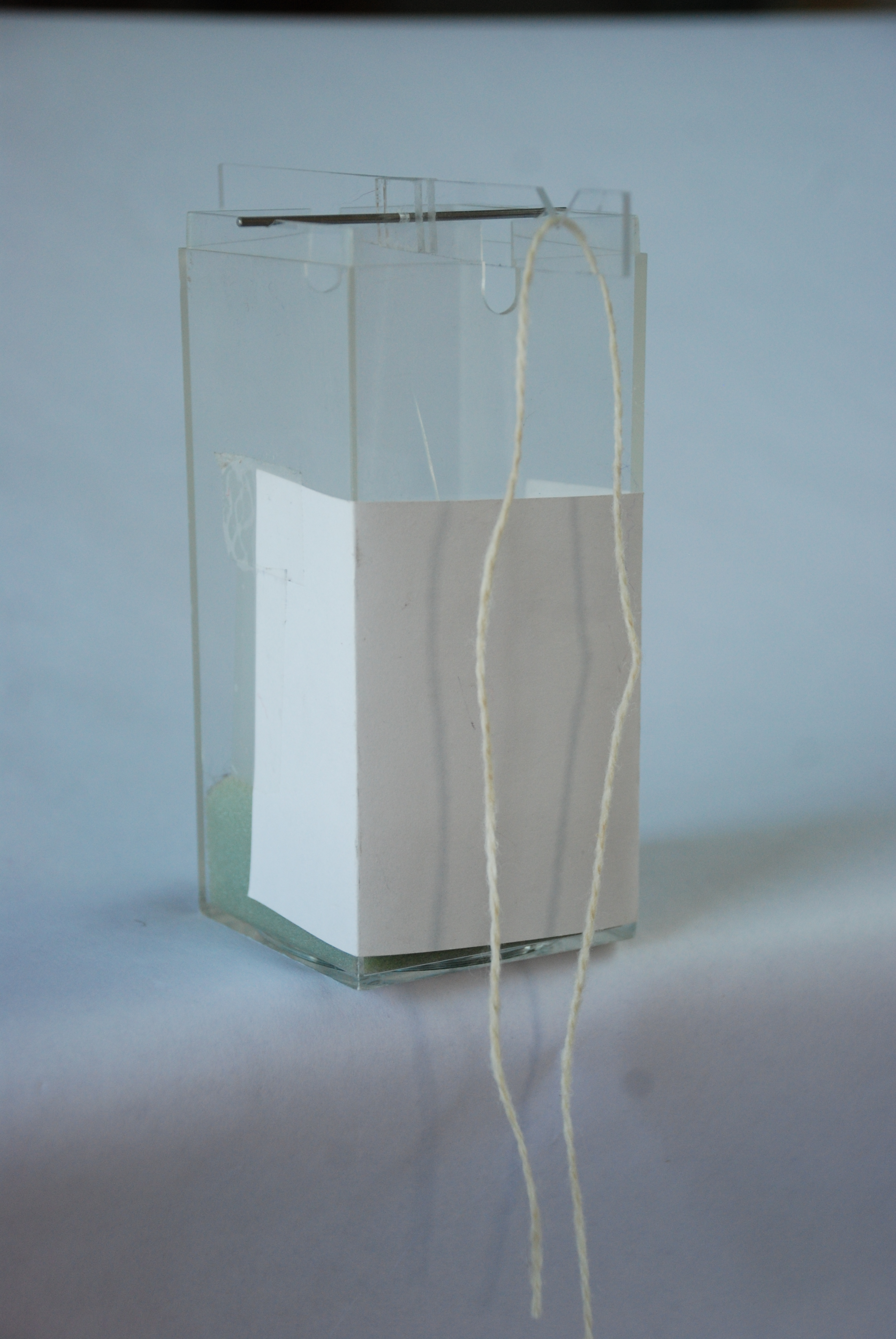

I hadn’t had a chance to do anything with it until recently. The first step was to gather some information.

I hadn’t had a chance to do anything with it until recently. The first step was to gather some information. The McMorran yarn balance is one tool to do that. You trim the ends off a strand of yarn until the arm balances.

The McMorran yarn balance is one tool to do that. You trim the ends off a strand of yarn until the arm balances. Then you measure that length of yarn and multiply by 100 to get ypp (yards/pound). I repeated that a few times to get an average–1500 ypp.

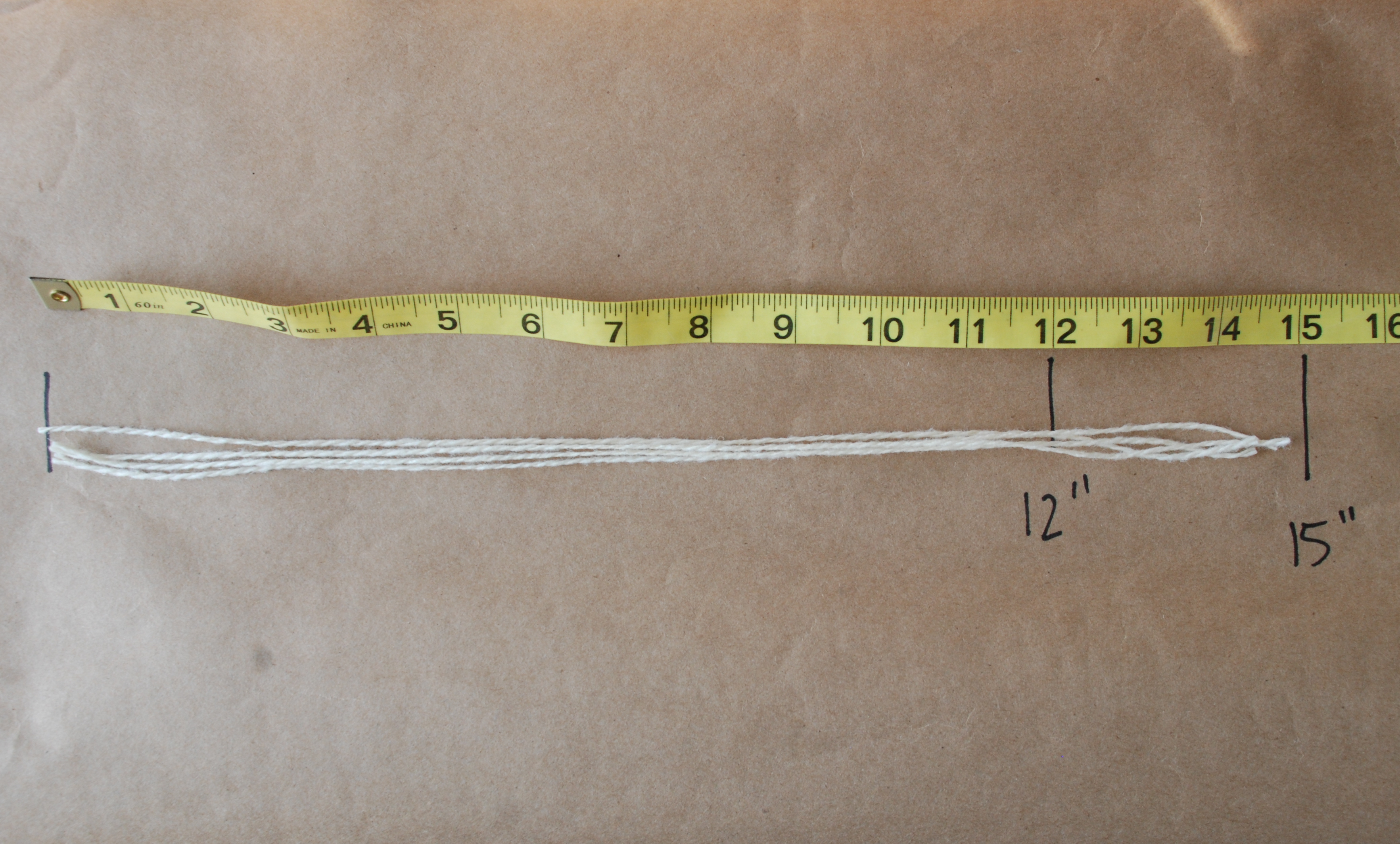

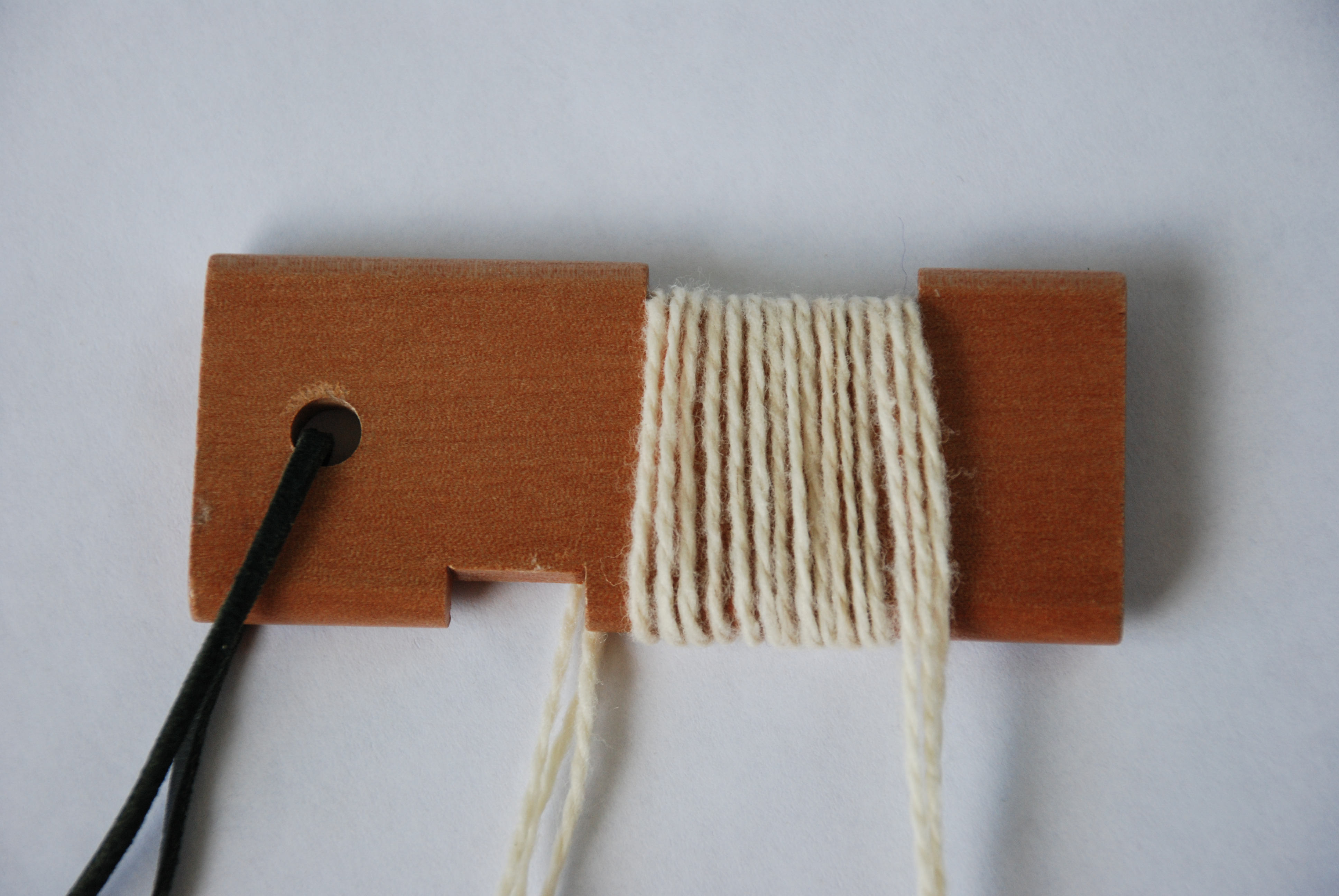

Then you measure that length of yarn and multiply by 100 to get ypp (yards/pound). I repeated that a few times to get an average–1500 ypp. Another measurement is wpi (wraps/inch). This yarn measure 15 wpi. However, from past experience I know that this isn’t quite accurate. Most yarn is scoured (washed) and skeined before it is sold in yarn stores. That can have a dramatic effect on the yarn. The yarn that I got from the mill on cones has not been scoured yet, so it is not really “finished”.

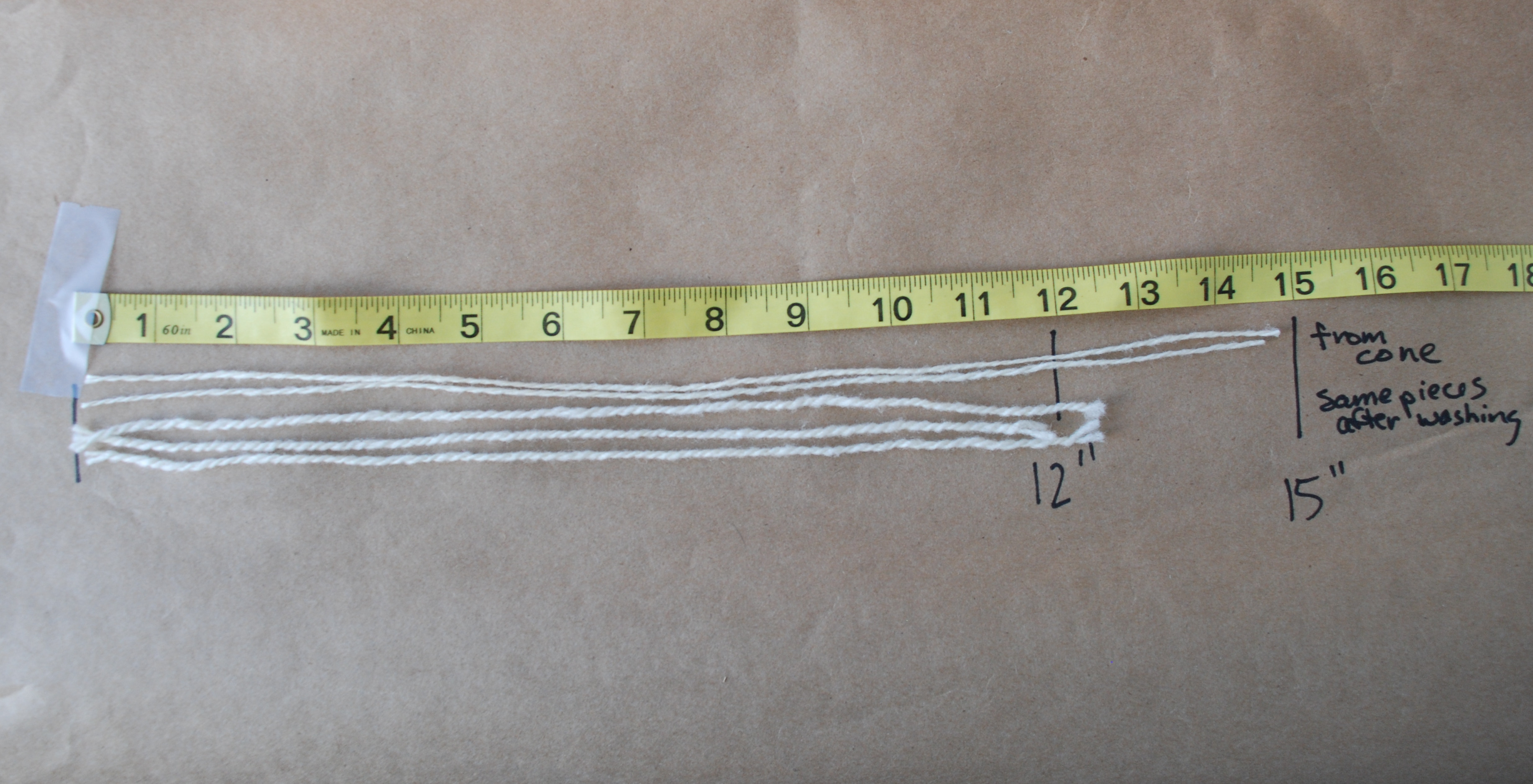

Another measurement is wpi (wraps/inch). This yarn measure 15 wpi. However, from past experience I know that this isn’t quite accurate. Most yarn is scoured (washed) and skeined before it is sold in yarn stores. That can have a dramatic effect on the yarn. The yarn that I got from the mill on cones has not been scoured yet, so it is not really “finished”. Look at the difference a soak in warm water makes. Now this yarn measure 1200 ypp (which is what the specs from the mill were)…

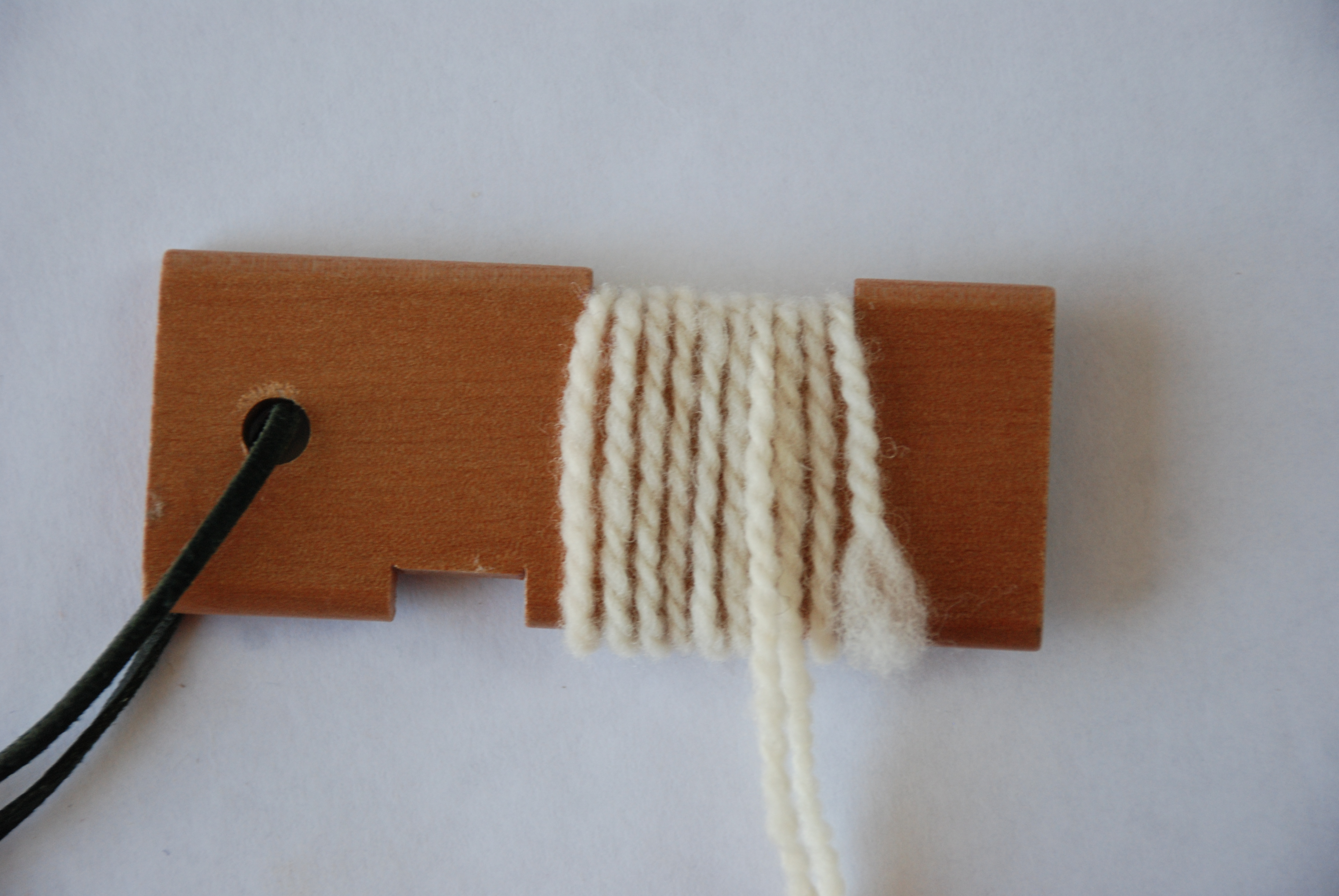

Look at the difference a soak in warm water makes. Now this yarn measure 1200 ypp (which is what the specs from the mill were)… and it is 10 wpi. Based on those measurements I wove some samples.

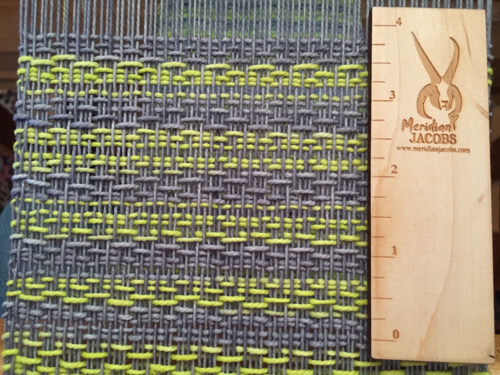

and it is 10 wpi. Based on those measurements I wove some samples. These samples look pretty open on the loom…

These samples look pretty open on the loom… …and I had to be careful to not beat the weft yarn down too much.

…and I had to be careful to not beat the weft yarn down too much. This is how the samples look off the loom. The 8 epi samples are in the top row.

This is how the samples look off the loom. The 8 epi samples are in the top row. And here is how they look after a quick wash. Dramatic difference from the loom to the finished fabric.

And here is how they look after a quick wash. Dramatic difference from the loom to the finished fabric. Here is how I had them displayed in the shop at the recent Shearing Day. The skein on the left has been washed. But these yarns aren’t just for weaving. My friend, Mary, bought some, washed it, and then used it for a Mystery Knit Along. Here is the shawl she knit.

Here is how I had them displayed in the shop at the recent Shearing Day. The skein on the left has been washed. But these yarns aren’t just for weaving. My friend, Mary, bought some, washed it, and then used it for a Mystery Knit Along. Here is the shawl she knit. This was knit over a few weeks with a new direction given out each week.

This was knit over a few weeks with a new direction given out each week. It is gorgeous in person and has a wonderful hand. I can’t wait to get some of this yarn on the loom and get to work with it.

It is gorgeous in person and has a wonderful hand. I can’t wait to get some of this yarn on the loom and get to work with it. For this month’s show we invited our family members to join us in sharing their art work.

For this month’s show we invited our family members to join us in sharing their art work. My sons and daughter-in-law entered their photos. Sorry that my photos don’t show theirs very well. Chris took photos while on the fire line last summer. Matt and Kaleena’s photos are taken in their “backyard” of the El Dorado National Forest. I wove 7 Fire scarves and 5 Sky scarves so that I could choose the ones I wanted to display with the photos. You can’t tell from this but the Fire scarves have sparkles (and have a lot more color variation than shows up here).

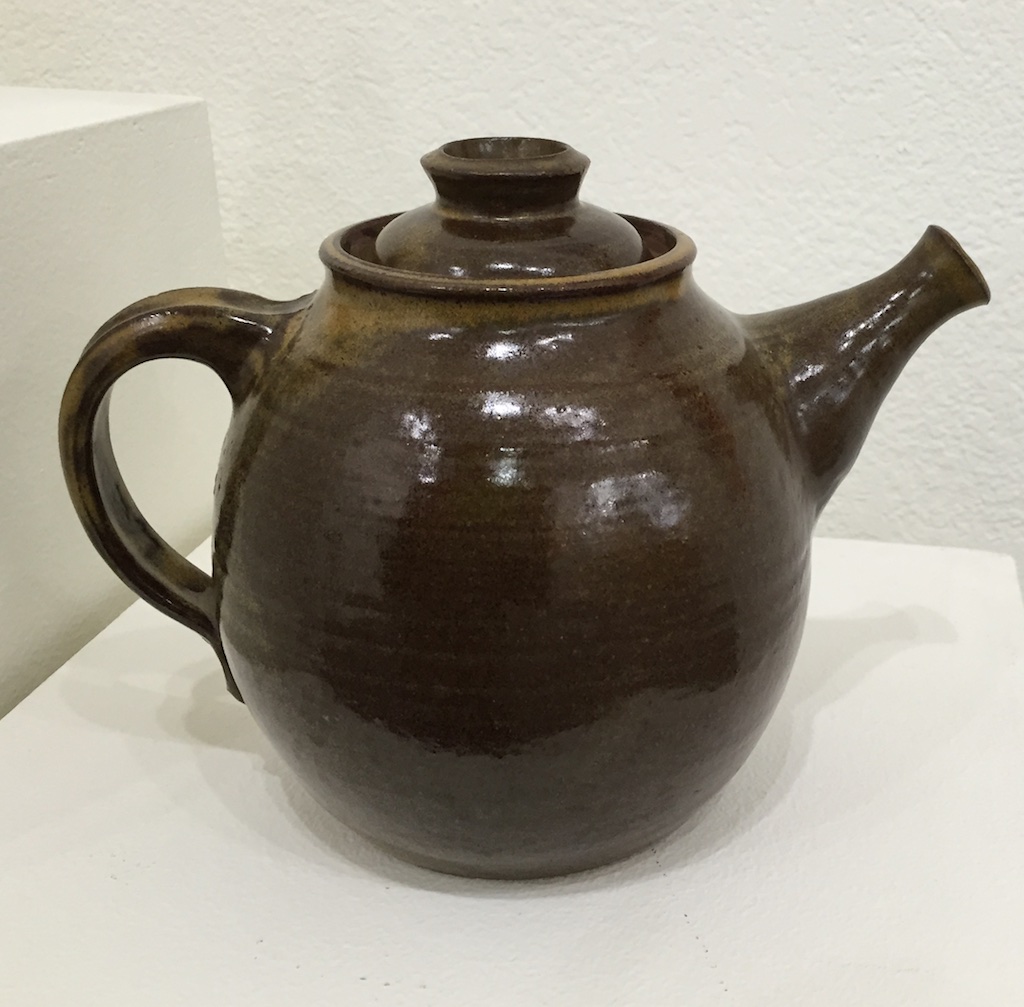

My sons and daughter-in-law entered their photos. Sorry that my photos don’t show theirs very well. Chris took photos while on the fire line last summer. Matt and Kaleena’s photos are taken in their “backyard” of the El Dorado National Forest. I wove 7 Fire scarves and 5 Sky scarves so that I could choose the ones I wanted to display with the photos. You can’t tell from this but the Fire scarves have sparkles (and have a lot more color variation than shows up here). I also included two of my mom’s pieces. She was always proud of her teapots because she could create a dripless spout.

I also included two of my mom’s pieces. She was always proud of her teapots because she could create a dripless spout.  Mom mostly made functional pieces like plates, bowls, and mugs, but also made tiles for the kitchen, a bathroom sink (the actual sink !), lanterns, birdbaths, and a sundial. This is a rare statement on society…

Mom mostly made functional pieces like plates, bowls, and mugs, but also made tiles for the kitchen, a bathroom sink (the actual sink !), lanterns, birdbaths, and a sundial. This is a rare statement on society… …but I’m not really sure what she meant.

…but I’m not really sure what she meant. I took only a few more photos in the gallery because I ran out of time. Artery member Marjan made the 3-D flowers and her mom did the silk paintings.

I took only a few more photos in the gallery because I ran out of time. Artery member Marjan made the 3-D flowers and her mom did the silk paintings. Heidi’s husband and dad collaborated with her making bowls.

Heidi’s husband and dad collaborated with her making bowls. Sorry, but I don’t remember whose work this is but it is all felt, including the rocks.

Sorry, but I don’t remember whose work this is but it is all felt, including the rocks. Here is a wild “Dragon Drawn in Space” above member Chris’ family’s art.

Here is a wild “Dragon Drawn in Space” above member Chris’ family’s art. My regular work moved out of the gallery and is in the front of the Artery for the next month or two.

My regular work moved out of the gallery and is in the front of the Artery for the next month or two.