After all the thoughts I had about keeping up with blog posts I see that the last post was the day after Christmas. I sure write a lot of blog posts in my head and even take the photos. Best laid plans and all…

We are shearing on January 21 and I like to take photos of the sheep in full fleece so I can update the website. I just updated the Ram page and the Ewe page. I moved the lambs that I kept in 2023 to these pages so that is a record of the whole flock now.

Shearing is only 11 days away. If you are a fiber fanatic and want to attend shearing day contact me. Or maybe if you’re part of a fiber guild you have already seen an announcement. First lambs are due two weeks later.

Zora is the first one due and is pregnant with twins. Due date is February 5. All the others will start a week later.

Bessie sure looks big enough to have multiples, but the ultrasound showed one. Is it all wool?

Sweetgrass Eilwen is due at the end of February and has twins.

This will be Rose’s first lambs. She is carrying triplets and is due February 11. Eight ewes are due that first weekend. That is why I will not be demonstrating at the Sacramento Weavers Open House that weekend.

Janna is also due on the February 11 with triplets.

Patchwork Amara is the third ewe that according to ultrasound is carrying triplets. Her due date is the 21st.

Bide a wee Trista is due the 17th. Ultrasound notes say 1+. That means that one lamb is confirmed, but they couldn’t say for sure that there isn’t a second.

Columbine has twins and is one of the 8 ewes due on February 11 or 12. Of course the due date is only a guideline. Lambs could be a few days before or after that date. I have to be paying attention. Looking at this photo, I remember that she had a wool break early in the year while nursing 2023 lambs. You can tell that some of her fleece is shorter than the rest. So this will not be a prime fleece. It’s possible that it can be salvaged. If not it will become part of next year’s Gardener’s Gold, a soil amendment for houseplants or the garden and made just down the road! It is available on line or here at the shop.

We have 45 ewes that will all lamb in February. The barn will be full!

It’s hard to imagine now with unseasonably low-70’s daytime highs for the last few days and predicted for the next week, but during most of January we had fog and drizzle. On he morning of our Farm Day this was what the brush pile looked like–a wool flower forest.

It’s hard to imagine now with unseasonably low-70’s daytime highs for the last few days and predicted for the next week, but during most of January we had fog and drizzle. On he morning of our Farm Day this was what the brush pile looked like–a wool flower forest. I don’t really like to see this because it means the sheep are rubbing on these branches.

I don’t really like to see this because it means the sheep are rubbing on these branches. We are shearing tomorrow. This is Cindy in full fleece.

We are shearing tomorrow. This is Cindy in full fleece.  The lilac ram, Catalyst.

The lilac ram, Catalyst. I love Shelby’s blue eyes.

I love Shelby’s blue eyes. We caught each sheep and inspected their fleeces. Farm Club members get first dibs on fleeces on Shearing Day and they can pre-select them on our Farm Day.

We caught each sheep and inspected their fleeces. Farm Club members get first dibs on fleeces on Shearing Day and they can pre-select them on our Farm Day.

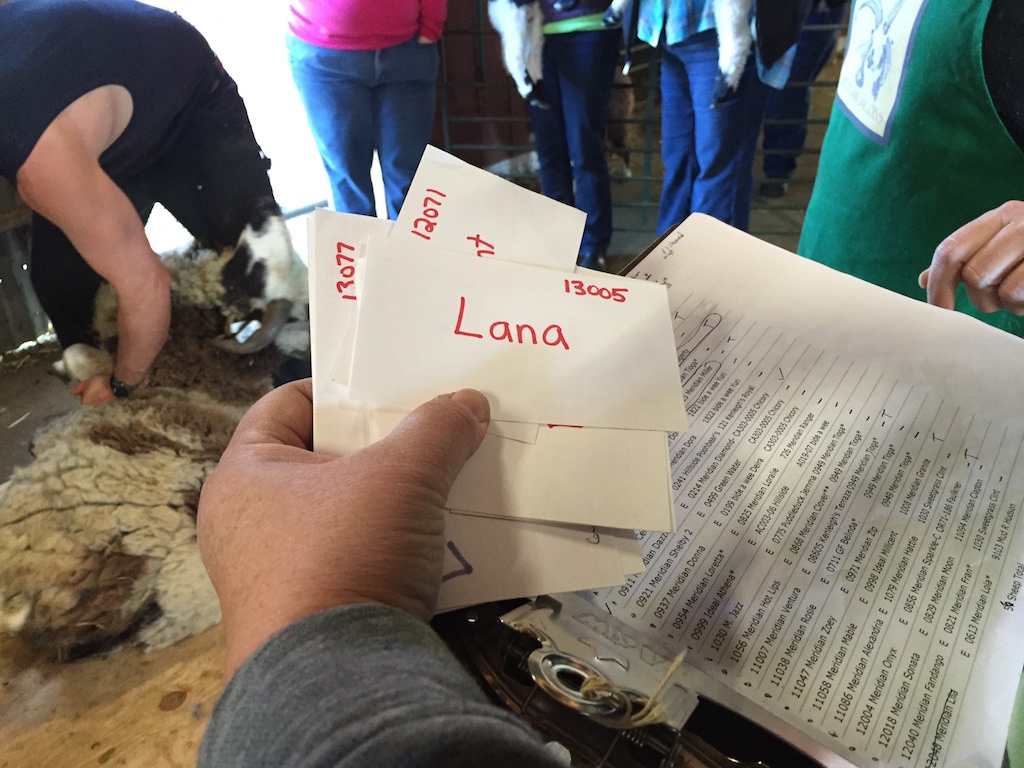

We also clean the ear tags so that they will be easy to read on Shearing Day. That’s Carole with the towel working on the tag.

We also clean the ear tags so that they will be easy to read on Shearing Day. That’s Carole with the towel working on the tag. Mary makes sure that fleece reservations are recorded on cards and that the ear tags match the ID on the card.

Mary makes sure that fleece reservations are recorded on cards and that the ear tags match the ID on the card. Another great day with Farm Club.

Another great day with Farm Club. I noticed that white line in the fleece of Terri, a 2017 lamb. I don’t have an explanation for that.

I noticed that white line in the fleece of Terri, a 2017 lamb. I don’t have an explanation for that. I love the ability to write on the photos on my phone.

I love the ability to write on the photos on my phone.

I hadn’t had a chance to do anything with it until recently. The first step was to gather some information.

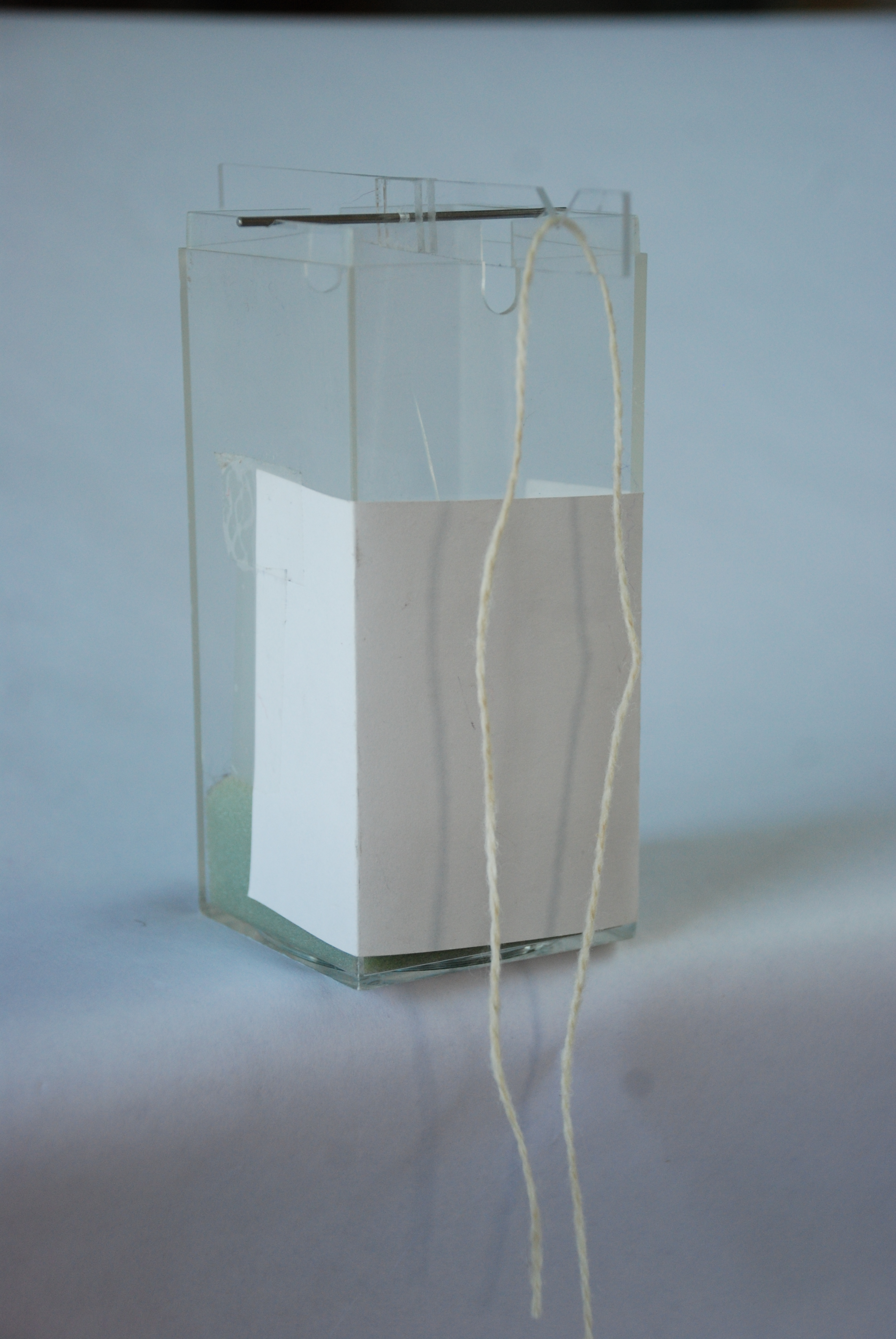

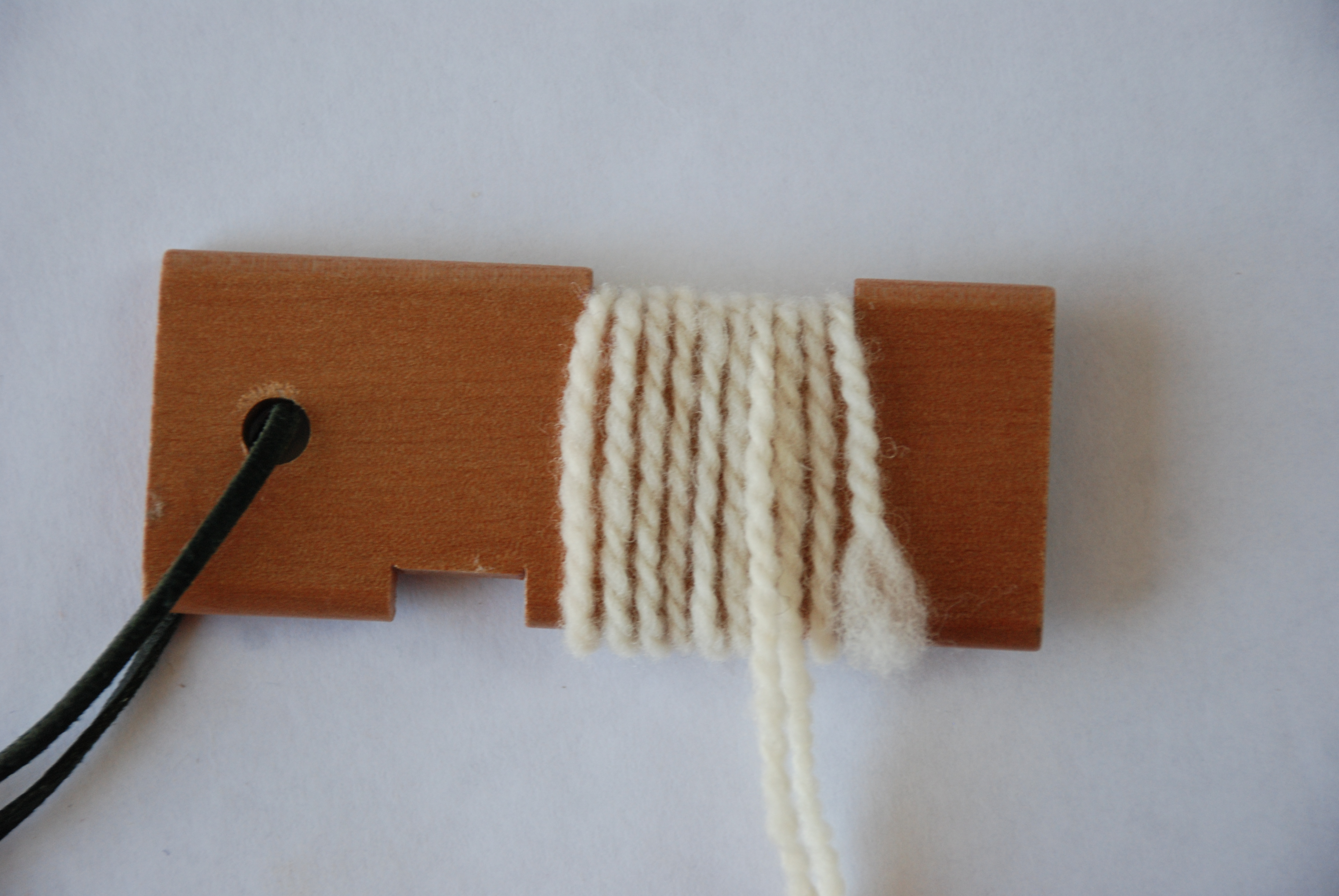

I hadn’t had a chance to do anything with it until recently. The first step was to gather some information. The McMorran yarn balance is one tool to do that. You trim the ends off a strand of yarn until the arm balances.

The McMorran yarn balance is one tool to do that. You trim the ends off a strand of yarn until the arm balances. Then you measure that length of yarn and multiply by 100 to get ypp (yards/pound). I repeated that a few times to get an average–1500 ypp.

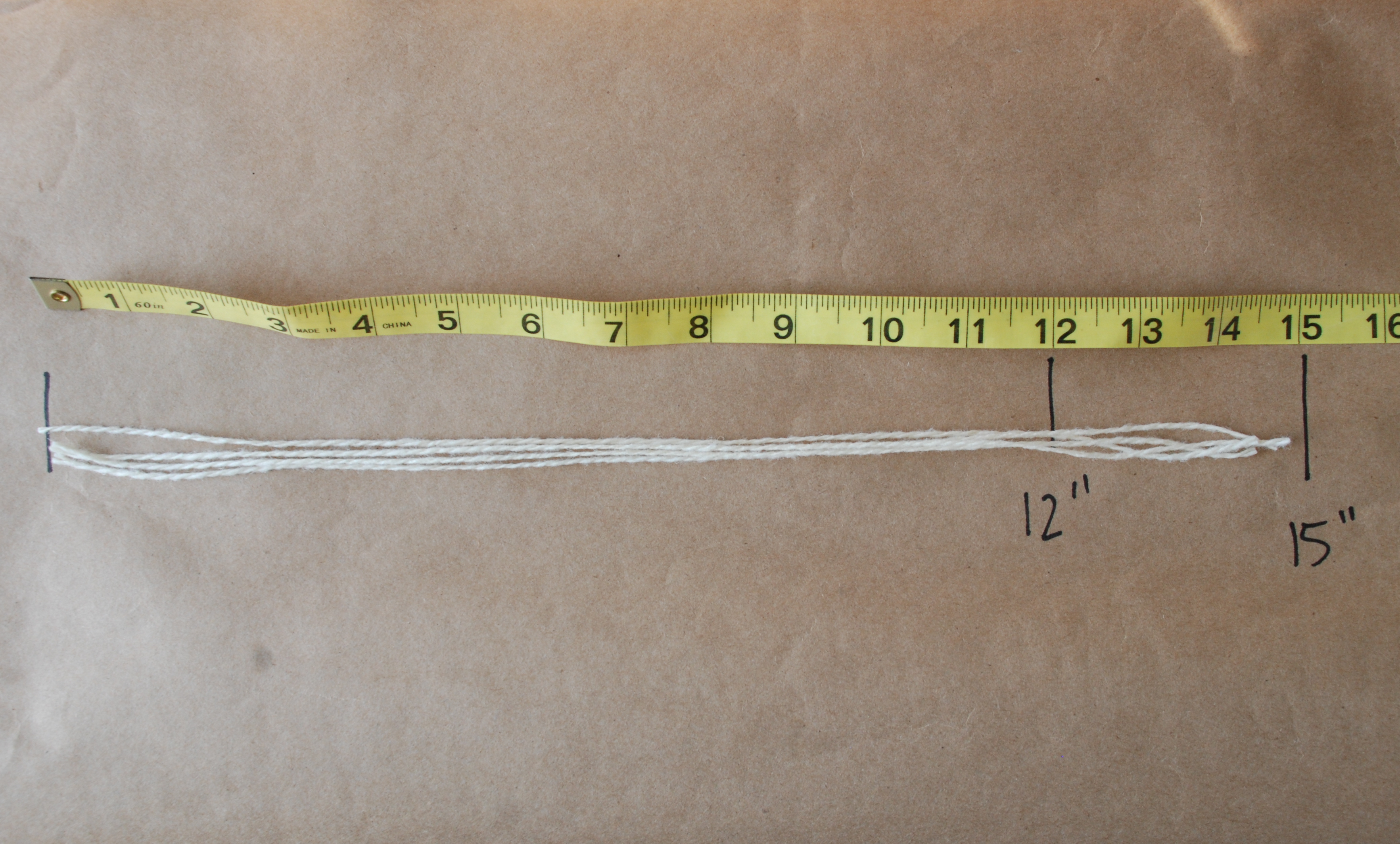

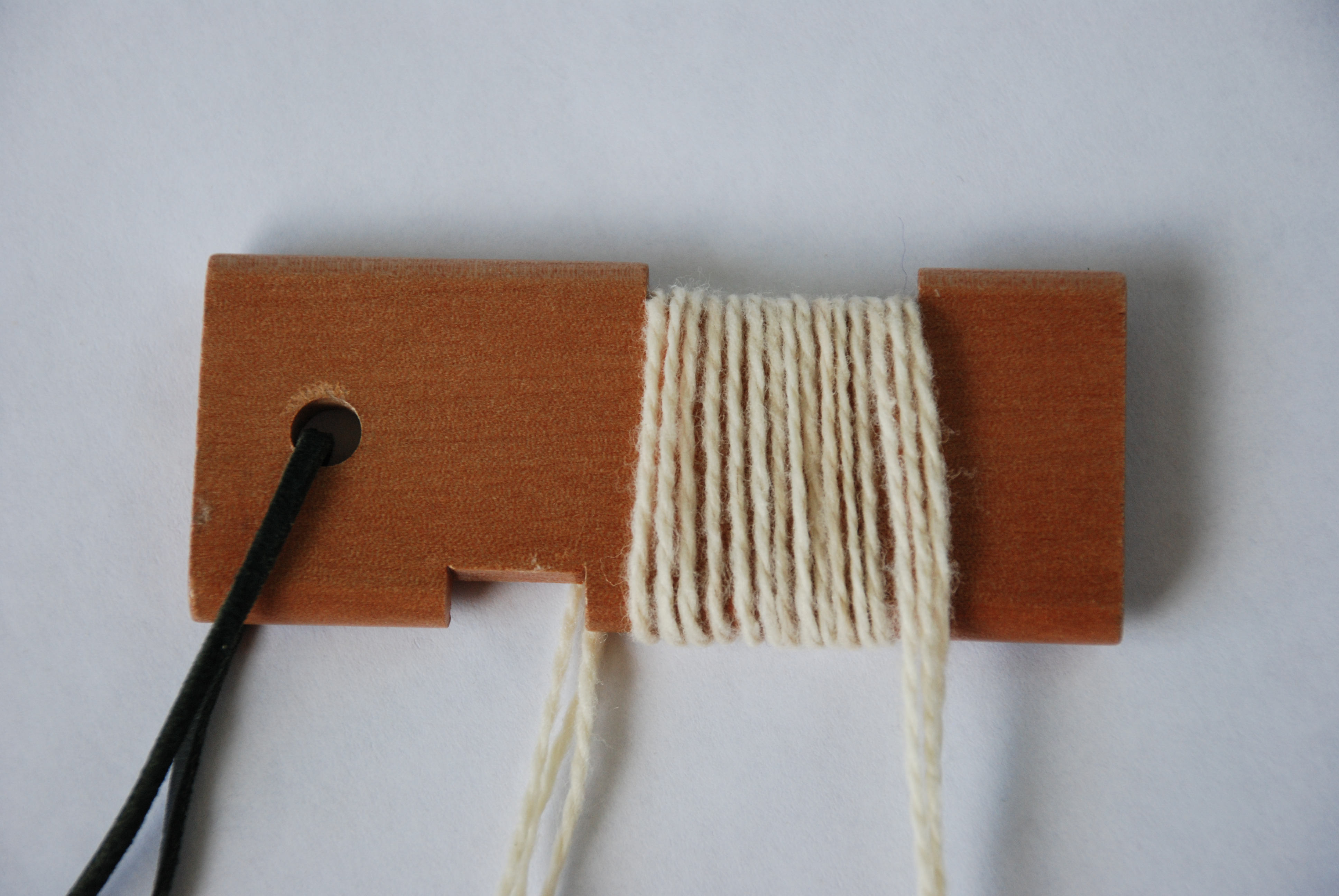

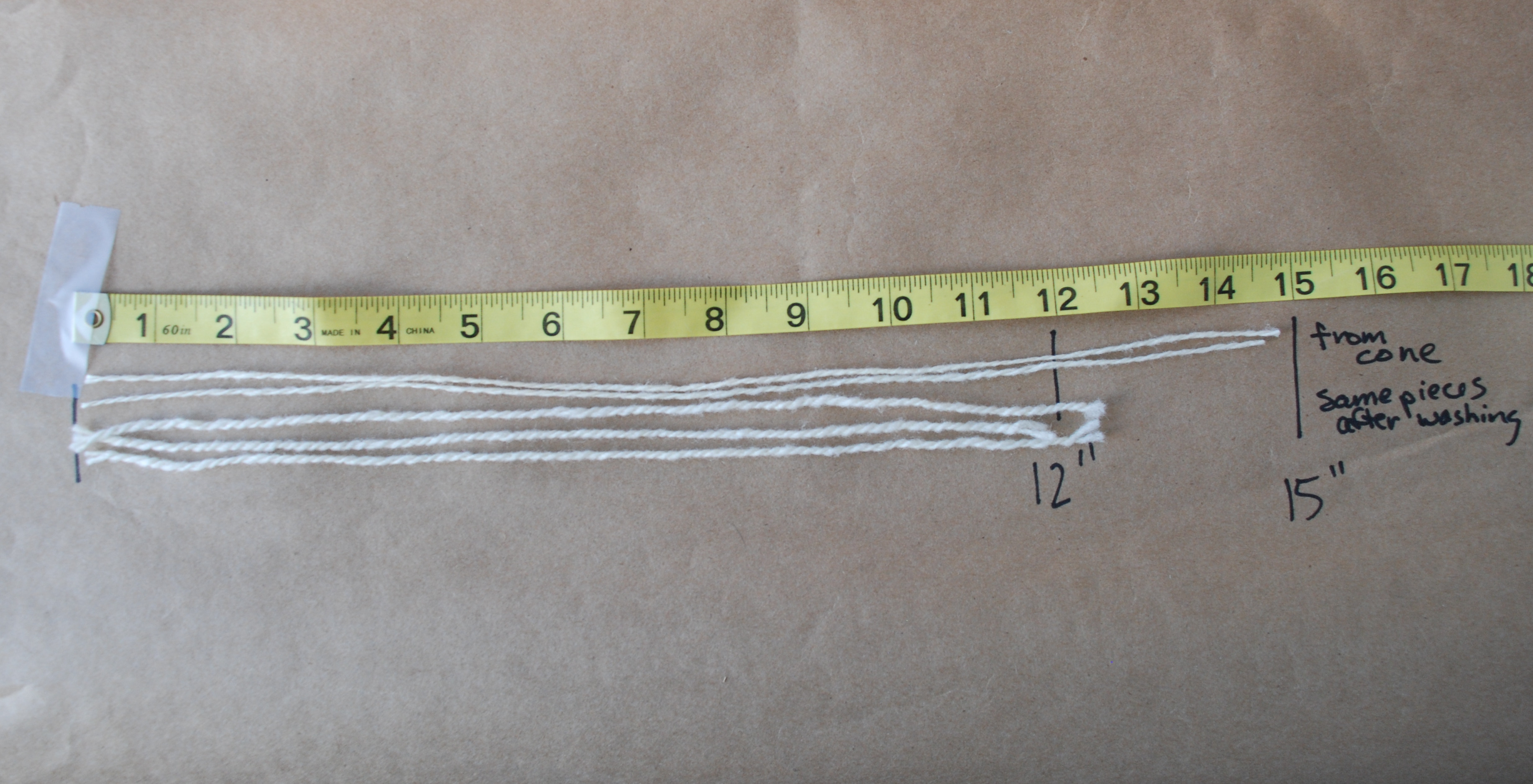

Then you measure that length of yarn and multiply by 100 to get ypp (yards/pound). I repeated that a few times to get an average–1500 ypp. Another measurement is wpi (wraps/inch). This yarn measure 15 wpi. However, from past experience I know that this isn’t quite accurate. Most yarn is scoured (washed) and skeined before it is sold in yarn stores. That can have a dramatic effect on the yarn. The yarn that I got from the mill on cones has not been scoured yet, so it is not really “finished”.

Another measurement is wpi (wraps/inch). This yarn measure 15 wpi. However, from past experience I know that this isn’t quite accurate. Most yarn is scoured (washed) and skeined before it is sold in yarn stores. That can have a dramatic effect on the yarn. The yarn that I got from the mill on cones has not been scoured yet, so it is not really “finished”. Look at the difference a soak in warm water makes. Now this yarn measure 1200 ypp (which is what the specs from the mill were)…

Look at the difference a soak in warm water makes. Now this yarn measure 1200 ypp (which is what the specs from the mill were)… and it is 10 wpi. Based on those measurements I wove some samples.

and it is 10 wpi. Based on those measurements I wove some samples. These samples look pretty open on the loom…

These samples look pretty open on the loom… …and I had to be careful to not beat the weft yarn down too much.

…and I had to be careful to not beat the weft yarn down too much. This is how the samples look off the loom. The 8 epi samples are in the top row.

This is how the samples look off the loom. The 8 epi samples are in the top row. And here is how they look after a quick wash. Dramatic difference from the loom to the finished fabric.

And here is how they look after a quick wash. Dramatic difference from the loom to the finished fabric. Here is how I had them displayed in the shop at the recent Shearing Day. The skein on the left has been washed. But these yarns aren’t just for weaving. My friend, Mary, bought some, washed it, and then used it for a Mystery Knit Along. Here is the shawl she knit.

Here is how I had them displayed in the shop at the recent Shearing Day. The skein on the left has been washed. But these yarns aren’t just for weaving. My friend, Mary, bought some, washed it, and then used it for a Mystery Knit Along. Here is the shawl she knit. This was knit over a few weeks with a new direction given out each week.

This was knit over a few weeks with a new direction given out each week. It is gorgeous in person and has a wonderful hand. I can’t wait to get some of this yarn on the loom and get to work with it.

It is gorgeous in person and has a wonderful hand. I can’t wait to get some of this yarn on the loom and get to work with it.

This is the yearling ram, Rotor.

This is the yearling ram, Rotor. A good comparison of a lilac Jacob (Nash) and black & white (Rotor).

A good comparison of a lilac Jacob (Nash) and black & white (Rotor). This is Rotor’s fleece.

This is Rotor’s fleece. They aren’t all spotted. This is one of the BFL-Jacob cross ewes.

They aren’t all spotted. This is one of the BFL-Jacob cross ewes. Lots of people help to make Shearing Day fun and easy for me. Kathleen weighed fleeces.

Lots of people help to make Shearing Day fun and easy for me. Kathleen weighed fleeces. Stephany and Gynna wrangled sheep all morning.

Stephany and Gynna wrangled sheep all morning. Alison and many others helped at the skirting table.

Alison and many others helped at the skirting table. People are welcome to skirt their fleeces before buying or ask for advice about fleeces.

People are welcome to skirt their fleeces before buying or ask for advice about fleeces.

It was a great day to stand in the sun with your hands in freshly shorn wool.

It was a great day to stand in the sun with your hands in freshly shorn wool. One more ewe to be shorn and then it was Faulkner’s turn.

One more ewe to be shorn and then it was Faulkner’s turn. His buddy, Jerry looked on. Faulkner weighed in at 235 lbs (down about 30 pounds from what he sometimes weighs in the summer).

His buddy, Jerry looked on. Faulkner weighed in at 235 lbs (down about 30 pounds from what he sometimes weighs in the summer). Fresh Jacob fleece.

Fresh Jacob fleece. Faulkner’s fleece.

Faulkner’s fleece. While the shearing and wool sorting was going on, friends were helping buyers in the shop.

While the shearing and wool sorting was going on, friends were helping buyers in the shop. Later we got everyone (almost) to the barn for a group photo. That’s a lot of enthusiastic friends!

Later we got everyone (almost) to the barn for a group photo. That’s a lot of enthusiastic friends! Sonata.

Sonata.

The BFL-cross named Ears.

The BFL-cross named Ears. This is Kenleigh’s Isadora.

This is Kenleigh’s Isadora. Vanessa.

Vanessa. Wesley is one of three wethers that are part of Ginny’s sheepdog training flock.

Wesley is one of three wethers that are part of Ginny’s sheepdog training flock. Wesley and Wally are BFL-crosses and the other two wethers in Ginny’s flock. They were all born at the fair in July.

Wesley and Wally are BFL-crosses and the other two wethers in Ginny’s flock. They were all born at the fair in July. This ram was also born at the fair. I’ll have to decide about shearing them since they will have only 6-month fleeces and it will be more of a stress on them.

This ram was also born at the fair. I’ll have to decide about shearing them since they will have only 6-month fleeces and it will be more of a stress on them. …a holiday craft project (above) and…

…a holiday craft project (above) and… …a photo op with our friendliest sheep dressed in her Christmas garb.

…a photo op with our friendliest sheep dressed in her Christmas garb. Here are some more ornaments that I made from locally grown and dyed wool.

Here are some more ornaments that I made from locally grown and dyed wool.

Much of the 2700 acres is leased for cattle grazing.

Much of the 2700 acres is leased for cattle grazing. The last gate before the ranch headquarters.

The last gate before the ranch headquarters.

The sheep are brought into the barn (on the left)…

The sheep are brought into the barn (on the left)…

These bales can weigh 300-400 pounds.

These bales can weigh 300-400 pounds.