I was ready to write another Random Farm Photos blog post but then thought that maybe, since this is the last day of the year, there should be some sort of retrospective. Most of my blog posts this year have been about the sheep and the pasture, but I am also a weaver. I have neglected that.

I keep a notebook with all my weaving info. The warps are numbered. I looked for the first one of 2025 and couldn’t find a photo. I sorted my photos into date order and found 275 photos in the weaving collection. Yikes! That doesn’t mean I wove that many pieces–not even close. But they all are part of various stories, none of which I shared in my blog. Maybe forget the sheep for a while and focus on yarn?

This is the issue of Little Looms, Summer 2025, with my clasped warp scarves in cotton. They were woven the previous year, but the magazine was published this year.

These are samples, all woven the same size in three different wool yarns. This is the photo after I took them off the loom but before any finishing. Wet finishing is the topic of an article in an upcoming issue of WEFT magazine. There were some surprises but you will have to wait for the magazine to be published to find out!

This is a workshop sampler for my Learn to Weave class. I taught this at the Conference of Northern California Handweavers (CNCH) in the spring and wanted new cotton samples. Students have the option of weaving wool or cotton in this class. You can’t tell from this view but every 6″ is a different treadling pattern. The green and white one gives four samples in one for each treadling by showing white on white, green on green, and the green/white blend.

Another sampler. This one is to experiment with color-and-weave using six colors. There will be an article featuring a project based on this in the Summer 2026 Handwoven magazine.

This is another scarf/shawl/wrap (which is it?) using Art Fiber Frenzy yarn. I have been intrigued by this yarn since I first discovered it a couple of years ago. I have also created a class to lead people through weaving a piece with so many fibers and textures.

I didn’t neglect my favorite fiber–wool. I wove several blankets and shawls during the year. This is one in a more traditional color-and-weave pattern with only two colors. The yarn is, of course, black and white Jacob wool.

This is a chenille scarf in shadow weave. It has sold but there may be a similar one at the Artery–I’ve lost track.

My new favorite wool (other than my Jacob and Timm Ranch yarns) is Brown Sheep Company Nature Spun. I’ll be introducing this for some of my classes this year. I wound some white v-shawl warps and space-dyed them. Then I needed to find weft colors.

Here is how the one on the right turned out.

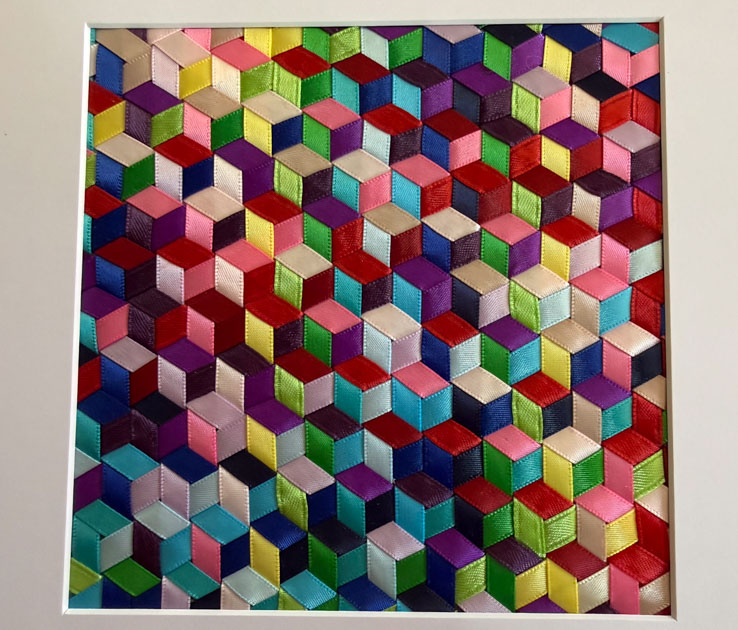

Oh boy! A crazy thing I got into was triaxial weaving. I wove some pieces 15 years ago and now have resurrected the idea. I spent way more hours on the four pieces I finished than maybe they warranted. But now I’m ready for more. Two will be in a January show at The Artery.

This is a v-shawl using the Nature Spun yarn. This one and the samples below are ideas for other articles I may propose and for pieces that I will sell.

Log cabin on the left is another color-and-weave pattern that looks much more complicated than it is.

If you read this blog regularly you know that I’ve been complaining about the fog, except for the beautiful sunny day we had two days ago. That didn’t last. It’s foggy again and it’s supposed to rain later. The “shop” where I have my bigger looms is not insulated and I don’t even try to heat it up with space heaters. I will put the heater on right next to me but It won’t have much impact on the surroundings. I am trying to finish the baby blankets that have been on this loom since October. That may be another blog post when I actually finish.

I worked on this loom yesterday and plan to finish today. First I need to put some more layers on.